engine

A technology of engine and engine block, which is applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc. It can solve the problems of restricting the development space of miniaturization of automobile displacement, short service life, low thermal power efficiency, etc., and achieve the goal of overcoming left and right Sloshing and side pressure wear, improved air tightness and service life, and improved energy saving and emission reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

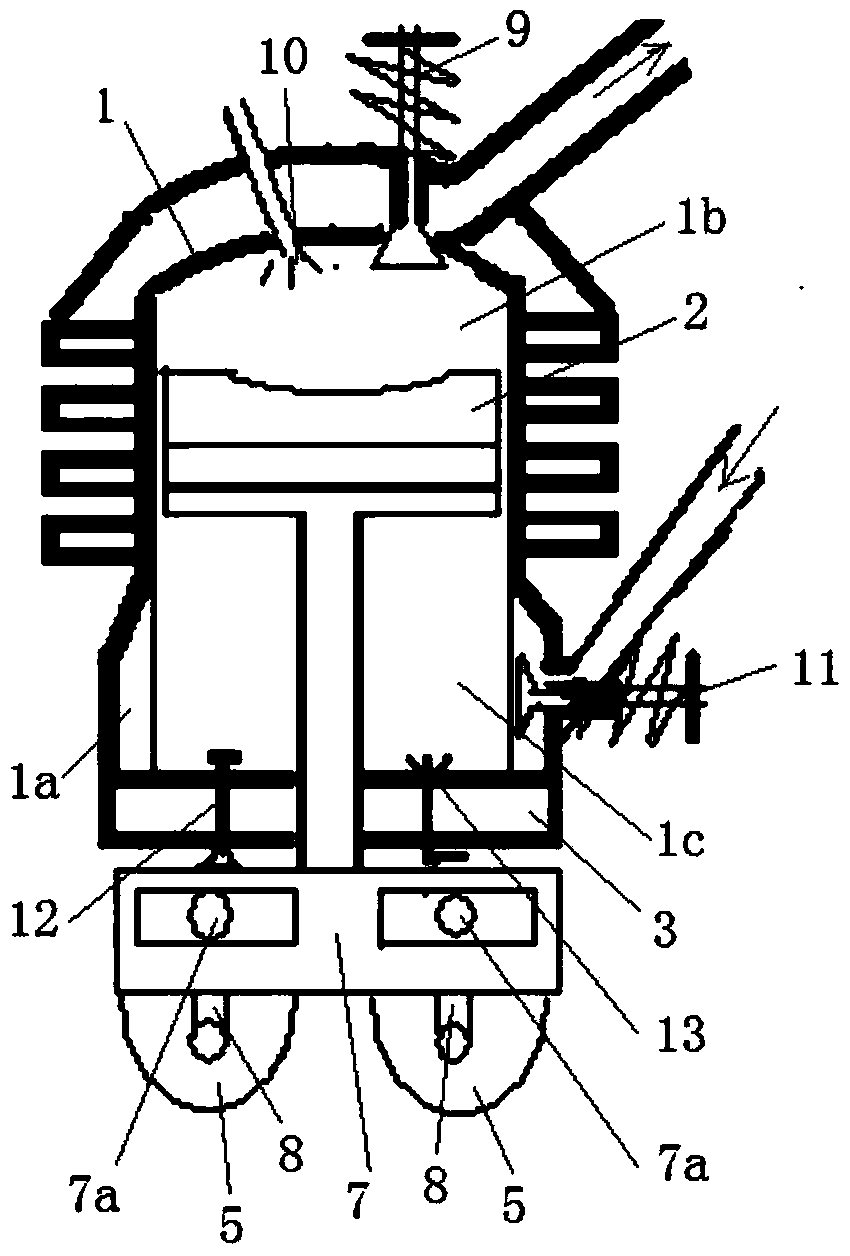

[0017] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

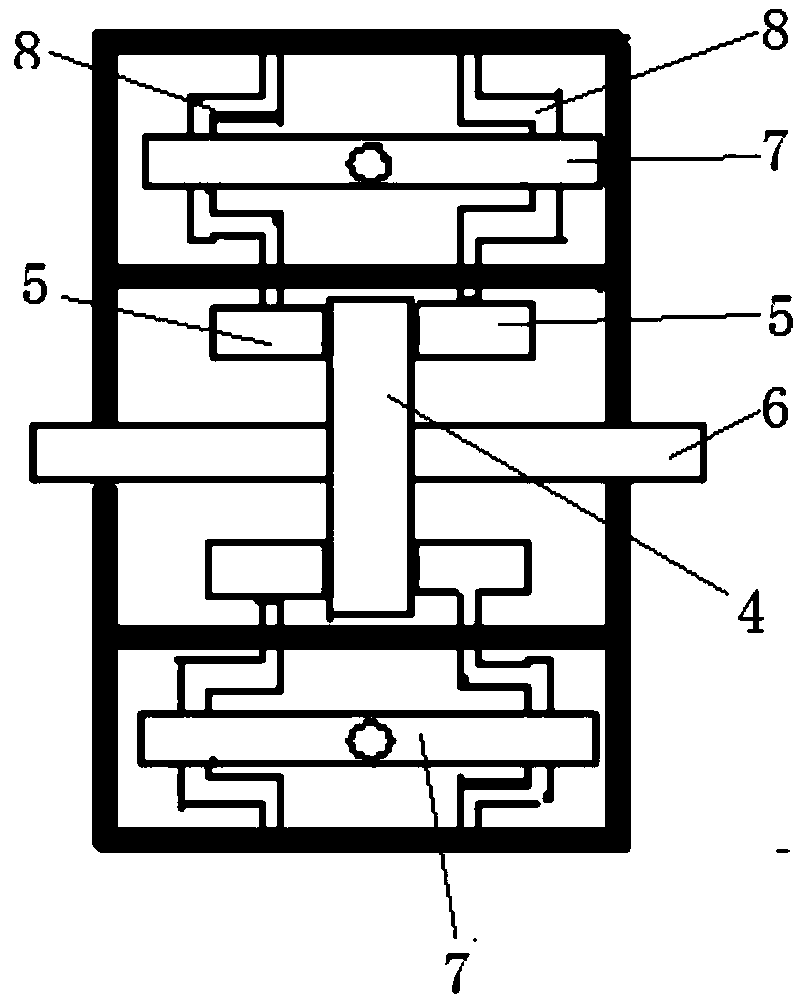

[0018] combine figure 1 — figure 2 Shown, a kind of engine mainly is made up of engine block 1, block piston 2, cylinder head 3, power output gear 4, drive gear flywheel 5, drive shaft 6, T-shaped push-pull rod 7, short arm crankshaft 8.

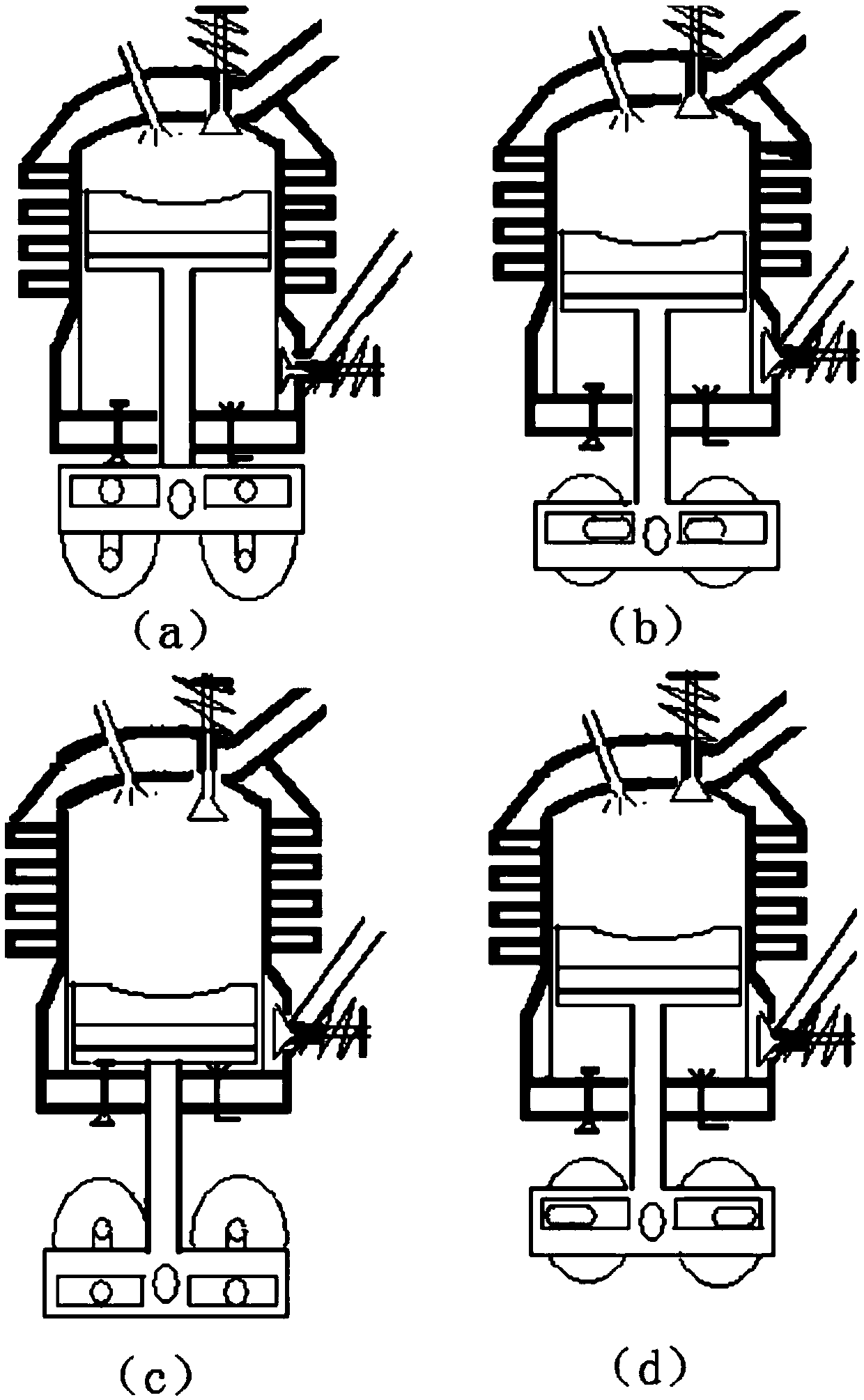

[0019] The top of the engine block 1 is provided with a fuel nozzle 10 and an exhaust valve 9 . The exhaust valve 9 is used to control the opening and closing of the exhaust hole of the engine block 1; fuel is injected into the engine block 1 through the fuel nozzle 10, such as the cylinder piston 2 moves up and down once, and the high-pressure gas is penetrated once, and the fuel nozzle 10 injects oil once, compression ignition works once, then the engine is in the two-stroke working mode; if the cylinder piston 2 moves up and down twice, high-pressure gas penetrates twice, the fuel nozzle 10 sprays oil once, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com