Light source optimization method for adaptive photoetching system

A lithography system and light source optimization technology, which is applied in the direction of micro-lithography exposure equipment, photolithography exposure device, etc., can solve the problem of reducing the complexity of the light source pattern, taking a long time, and not considering the impact of light source simplification on the imaging performance of the lithography system And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

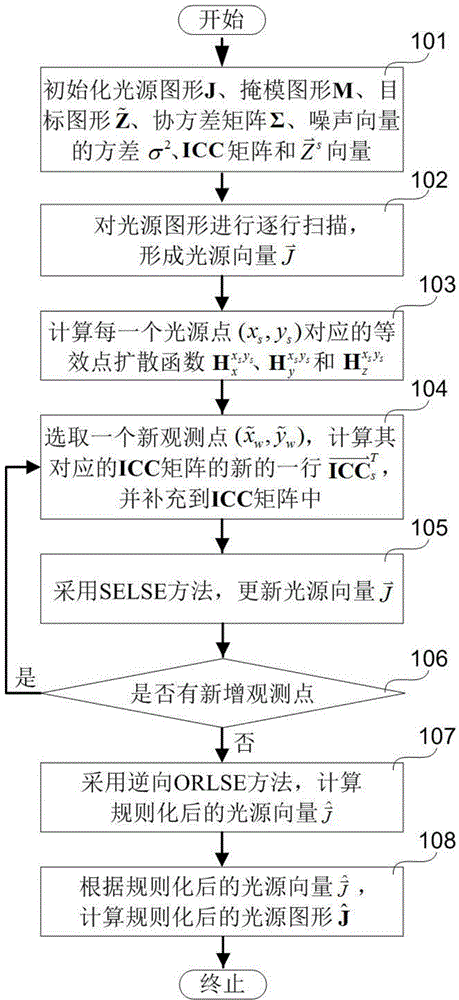

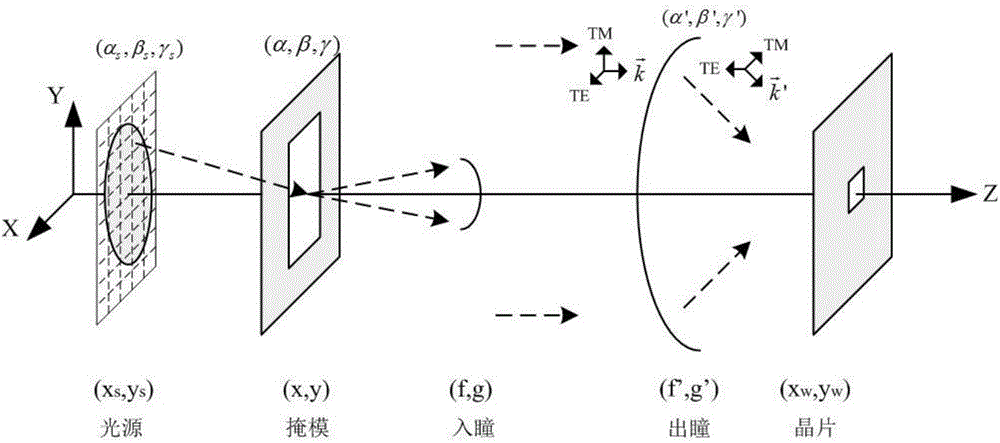

Method used

Image

Examples

Embodiment

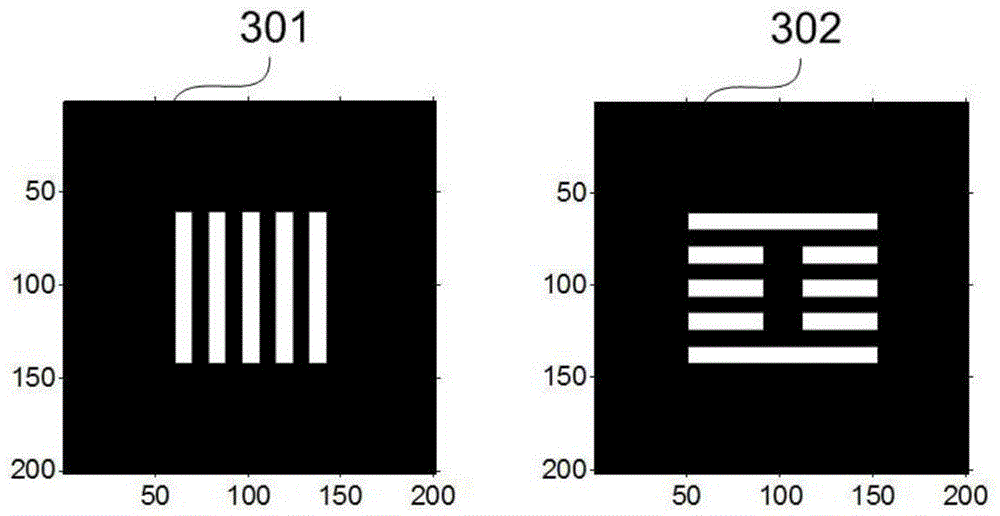

[0127] Such as image 3 Shown is a schematic diagram of two critical areas on the wafer, which are also target patterns, white represents the open area, black represents the light blocking area, and its critical dimension is 45nm. The lines in the key area indicated by 301 are along the vertical direction, and the lines in the key area indicated by 302 are along the horizontal direction.

[0128] Figure 4 is the initial light source graph, and the light source graph obtained after using the SELSE method to optimize the light source for the observation point data on the first key area. The initial light source shown in 401 is a ring light source; 402 is the result of optimizing the light source by using the SELSE method for the data of 2 observation points on the first key area; 403 is the result of optimizing the light source for 7 observations on the first key area The point data is the result of optimizing the light source by using the SELSE method; 404 is the result of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com