Egg collecting and grading integrated equipment

A technology for collecting eggs and equipment is applied in the improvement field of the egg grading system, which can solve the problems of damaged surface of eggs, pollution, low production efficiency, etc., and achieve the effects of reducing production costs, ensuring economic benefits, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

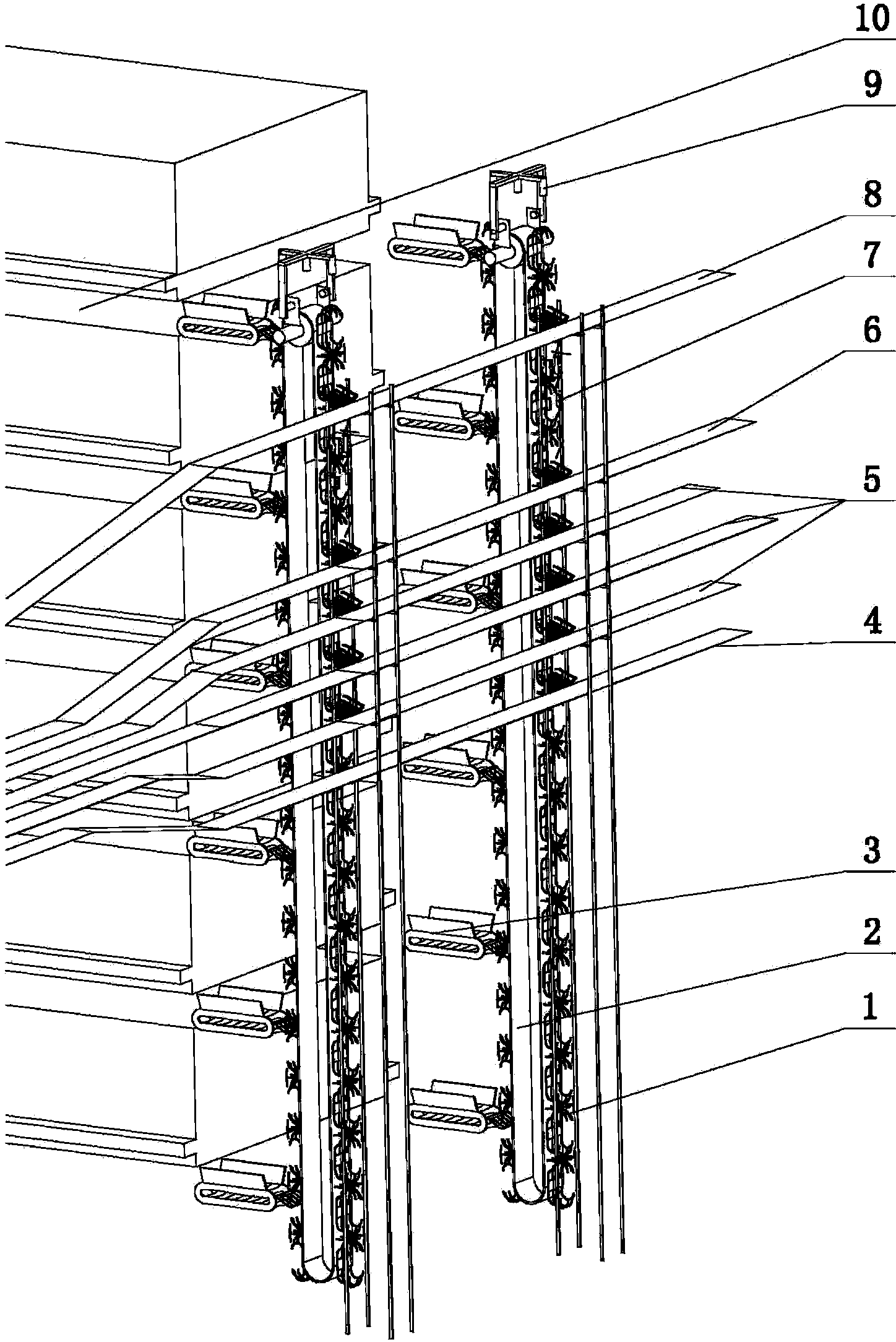

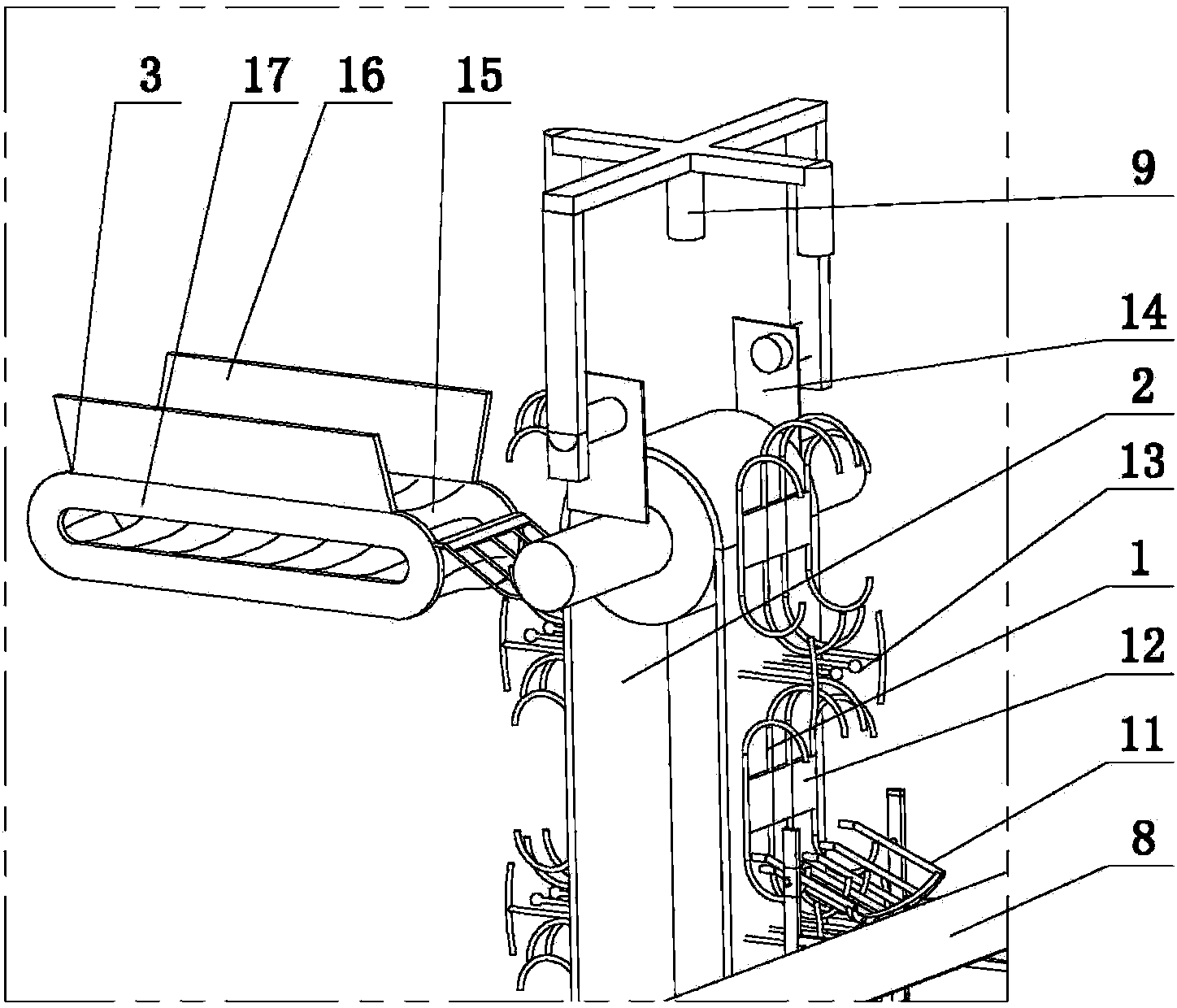

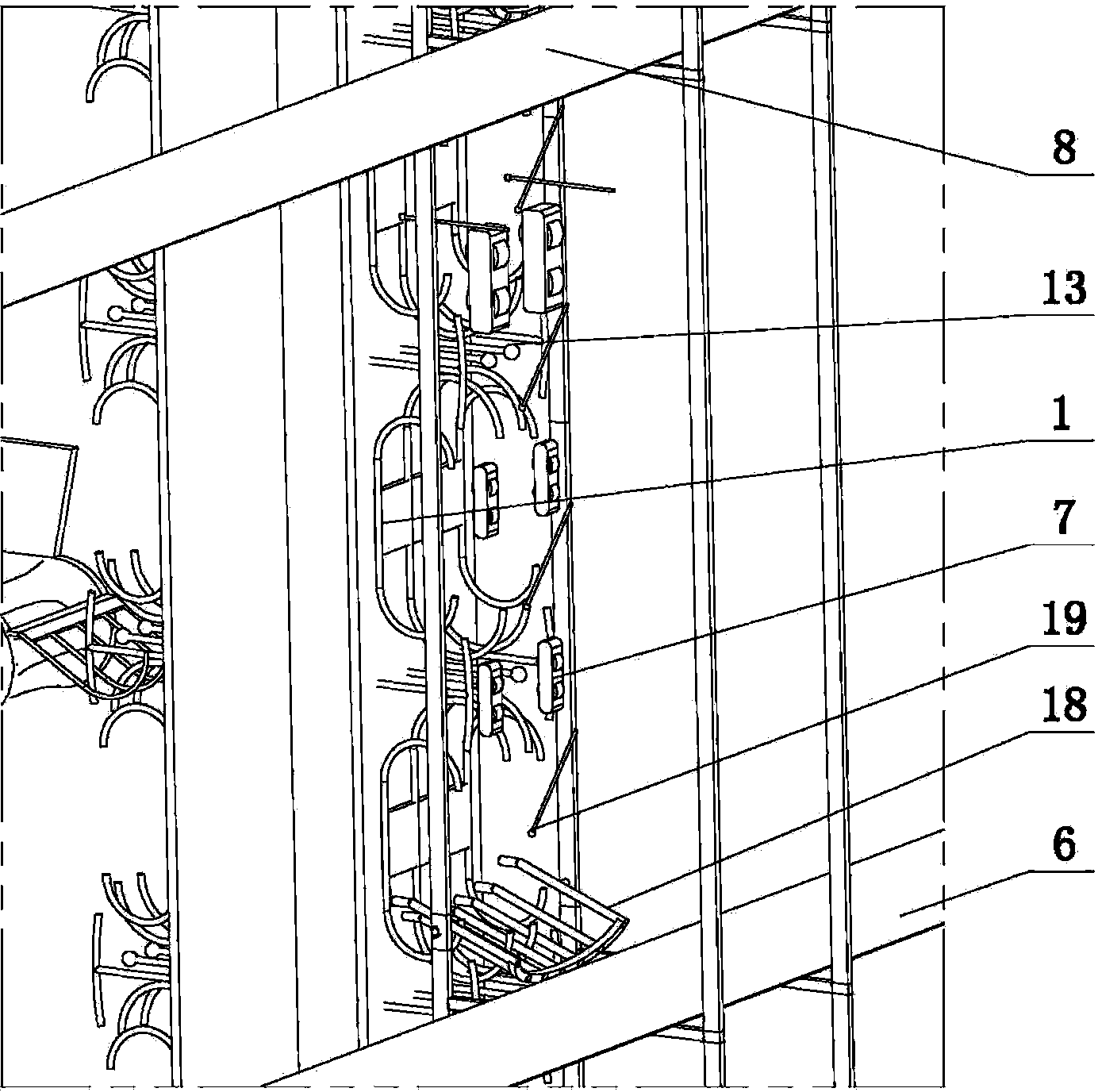

[0024] The present invention comprises an egg conveying device 3, a lifting conveying device 2 and at least two graded egg conveying devices 5 arranged vertically; A lever baffle 20 is provided through a rotating shaft between the egg delivery devices 5, and one end of the lever baffle 20 corresponds to the egg tray 1; 5 correspondingly; the counterweight on the lever baffle 20 increases sequentially from top to bottom.

[0025] An egg stopper 13 is arranged between the egg trays 1 and the egg trays 1 on the lifting transmission device 2 , and the egg stopper 13 can prevent poultry eggs from entering between the two egg trays 1 .

[0026] As a preferred solution of the present invention, a first egg conveying device 8 is arranged above the graded egg conveying device 5, and a first egg conveying device 8 is arranged between the first egg conveying device 8 and the lifting conveying device 2. Turning plate 11, the first turning plate 11 is provided with a first driving device;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com