Rice wet slurry automatic stone mill

A stone mill, wet pulp technology, applied in cocoa, grain processing, food science and other directions, can solve problems such as low work efficiency, high work noise, grinding tooth wear, etc., to achieve improved work efficiency, low manufacturing cost, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

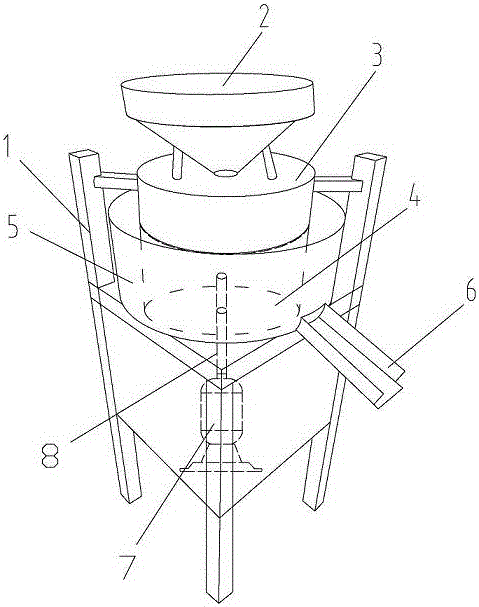

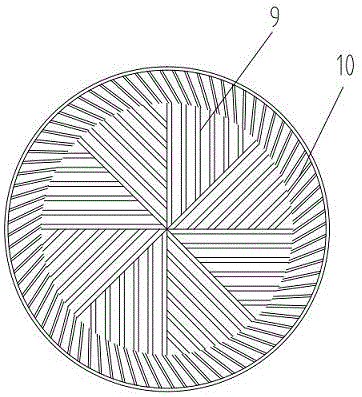

[0023] like Figure 1~2 As shown, the rice wet slurry automatic stone mill of the present invention includes a frame 1, a feed hopper 2, an upper grinding disc 3, a lower grinding disc 4, a grinding groove 5, a slurry outlet 6, a motor 7, a transmission shaft 8, a large grinding grain 9 and small grinding pattern 10, the upper grinding disc 4 is fixedly connected with the frame 1, the center of the upper grinding disc is provided with a feeding hole, the lower grinding disc 4 is arranged at the bottom of the upper grinding disc 3, and the described feeding funnel 2 is arranged on the upper The top of the millstone 3, the motor 7 is located at the bottom of the frame 1, the lower millstone 4 is connected with the motor 7 through the transmission shaft 8, and the friction surfaces of the upper millstone 3 and the lower millstone 4 are provided with grinding grains, and the milling grains include large grinding grains 9 and The small grinding lines 10 and the large grinding lines...

Embodiment 2

[0025] like Figure 1~2 As shown, the rice wet slurry automatic stone mill of the present invention includes a frame 1, a feed hopper 2, an upper grinding disc 3, a lower grinding disc 4, a grinding groove 5, a slurry outlet 6, a motor 7, a transmission shaft 8, a large grinding grain 9 and small grinding pattern 10, the upper grinding disc 4 is fixedly connected with the frame 1, the center of the upper grinding disc is provided with a feeding hole, the lower grinding disc 4 is arranged at the bottom of the upper grinding disc 3, and the described feeding funnel 2 is arranged on the upper The top of the millstone 3, the motor 7 is located at the bottom of the frame 1, the lower millstone 4 is connected with the motor 7 through the transmission shaft 8, and the friction surfaces of the upper millstone 3 and the lower millstone 4 are provided with grinding grains, and the milling grains include large grinding grains 9 and The small grinding lines 10 and the large grinding lines...

Embodiment 3

[0027] like Figure 1~2 As shown, the rice wet slurry automatic stone mill of the present invention includes a frame 1, a feed hopper 2, an upper grinding disc 3, a lower grinding disc 4, a grinding groove 5, a slurry outlet 6, a motor 7, a transmission shaft 8, a large grinding grain 9 and small grinding pattern 10, the upper grinding disc 4 is fixedly connected with the frame 1, the center of the upper grinding disc is provided with a feeding hole, the lower grinding disc 4 is arranged at the bottom of the upper grinding disc 3, and the described feeding funnel 2 is arranged on the upper The top of the millstone 3, the motor 7 is located at the bottom of the frame 1, the lower millstone 4 is connected with the motor 7 through the transmission shaft 8, and the friction surfaces of the upper millstone 3 and the lower millstone 4 are provided with grinding grains, and the milling grains include large grinding grains 9 and The small grinding lines 10 and the large grinding lines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com