General rotating ultrasonic transducer assembly of high-speed motorized spindle

A high-speed electric spindle and rotating ultrasonic technology, applied in the direction of the fluid using vibration, can solve the problems of inability to run at high speed, low emission efficiency of piezoelectric elements, heat generation and energy loss, etc., and achieve the consistency of product parameters and transmission efficiency. And the effect of improving reliability and reducing the difficulty of manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

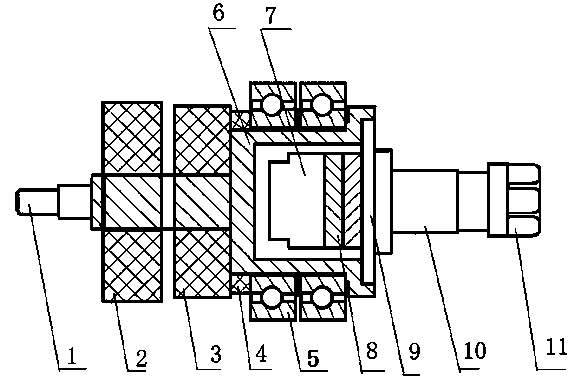

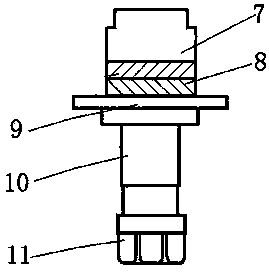

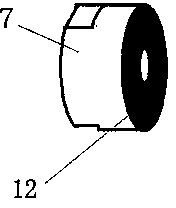

[0022] Such as figure 1 As shown, a high-speed electric spindle universal rotating ultrasonic transducer assembly according to the present invention includes a connecting shaft 1 and a transducer housing 6 of an integral structure, coaxially fixed on the connecting shaft 1 or the rear shaft end of the electric spindle The static unit 2 of the magnetic resonance transmitter and the rotating unit 3 of the magnetic resonance receiver, and the integrated ultrasonic transducer coaxially fixed inside the transducer housing 6; the bearing 5 is fixed on the transducer housing 6 through a nut 4; The ultrasonic transducer comprises an upper cover plate 7, a piezoelectric element 8, an integrated lower cover plate 9, a horn 10, and a cutting tool chuck 11, and the piezoelectric element 8 is arranged on the upper cover plate 7 and the lower cover betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com