Chitosan modification method

A chitosan and modification technology, applied in the field of modified chitosan, can solve the problems of weak specific recognition, inability to target recognition of asialoglycoprotein, complicated operation, etc., achieve easy availability of reagents and reduce production Cost, effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

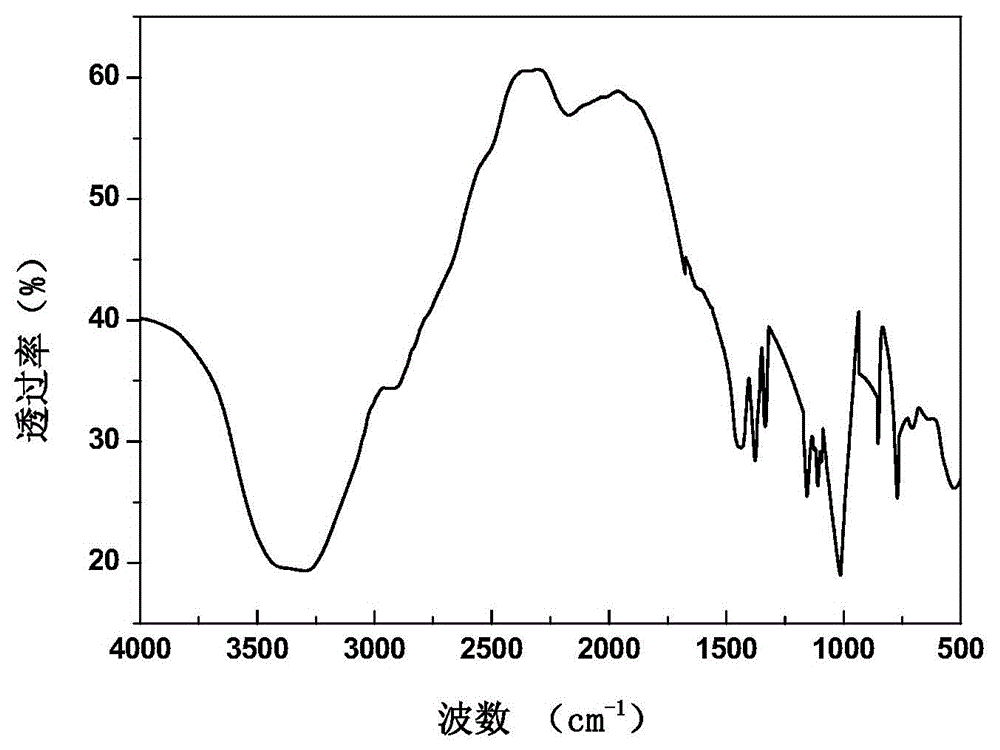

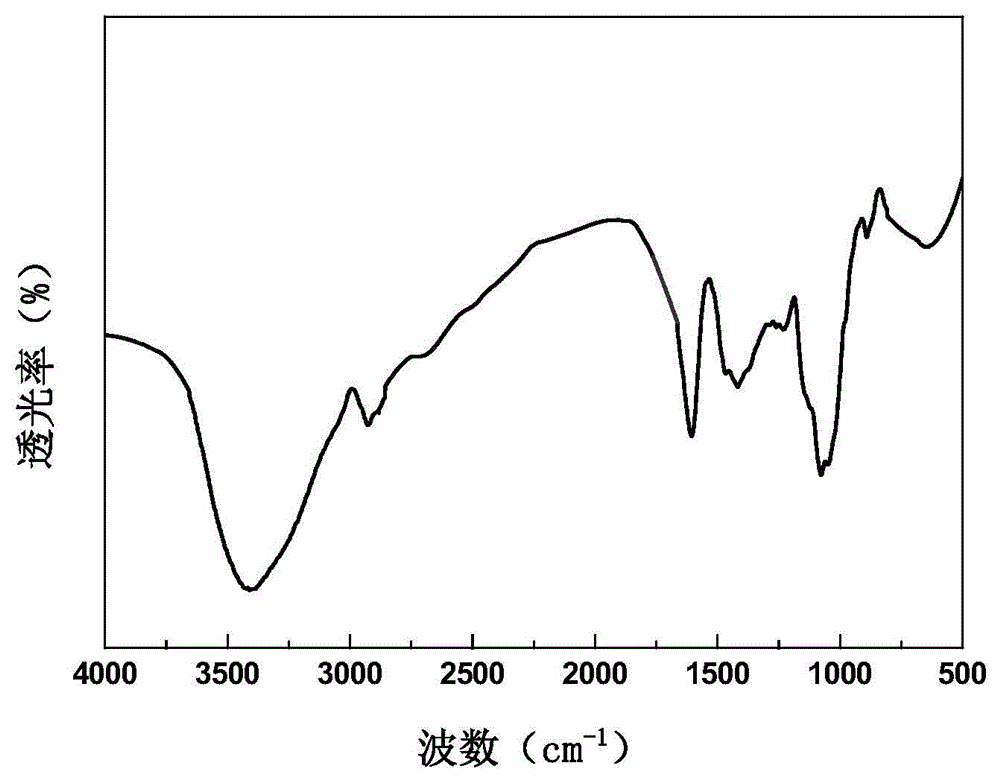

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: the method for a kind of modified chitosan described in the present embodiment is specifically carried out according to the following steps:

[0021] 1. Dissolving chitosan in dilute hydrochloric acid solution with a mass fraction of 1% to 20% to obtain acidified chitosan;

[0022] The volume ratio of the quality of the chitosan to the dilute hydrochloric acid solution with a mass fraction of 1% to 20% is 1g:(100 to 300) mL;

[0023] 2. Dissolving lactobionic acid in water to obtain a lactobionic acid solution;

[0024] The mass of the lactobionic acid and the volume ratio of water are 1g:(10~50)mL;

[0025] 3. Dissolving N,N'-dicyclohexylcarbodiimide in tetramethylethylenediamine to obtain activated N,N'-dicyclohexylcarbodiimide;

[0026] The volume ratio of the mass of N,N'-dicyclohexylcarbodiimide to tetramethylethylenediamine is 1g:(10-50)mL;

[0027] 4. Drop lactobionic acid solution and activated N,N'-dicyclohexylcarbodiimide into the a...

specific Embodiment approach 2

[0031] Specific embodiment two: what this embodiment is different from specific embodiment one is: the quality of the chitosan described in step one and mass fraction are that the volume ratio of the dilute hydrochloric acid solution of 1%~20% is 1g:(100~ 200) mL. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the volume ratio of the mass of lactobionic acid described in step 2 to water is 1 g:(20-50) mL. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com