Method for Improving Pressure Capability of Magnetic Fluid Sealing by Using Magnetic Nanowire Magnetic Fluid

A technology of magnetic liquid and pressure resistance, which is applied to engine seals, engine components, mechanical equipment, etc., can solve the problems of low pressure resistance of magnetic liquid seals and limit the application of magnetic liquid seals, and achieve the effect of improving pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

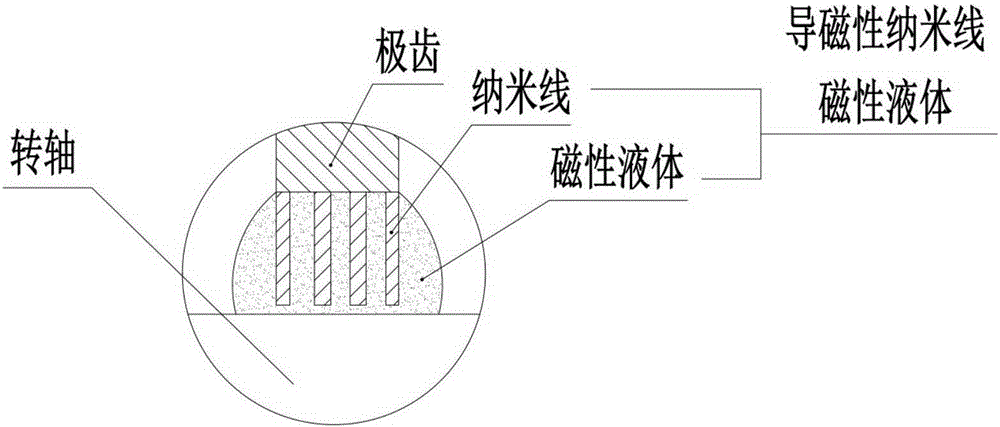

[0014] Firstly, in the solution in which the magnetically conductive nanowires are dissolved, the nanowires with a lateral size of 10-30 nm and a length of 100-150 μm are screened out. Then add the above-mentioned nanowires with a volume of 5% of the volume of the magnetic liquid in the purchased fluorocarbon-based magnetic liquid, and add an appropriate amount of surfactant to prevent the precipitation of the nanowires, and stir for 40 minutes to form a magnetic nanowire magnetic liquid. . The magnetic liquid of the magnetically permeable nanowire is injected into the sealing gap sealed by the magnetic liquid.

Embodiment approach 2

[0016] First, in the solution in which the magnetically conductive nanowires are dissolved, the nanowires with a lateral dimension of 30-70 nm and a length of 150-250 μm are screened out. Then, add the above-mentioned nanowires with a volume of 6% of the volume of the magnetic liquid to the purchased ester-based magnetic liquid, and add an appropriate amount of surfactant to prevent the precipitation of the nanowires, and stir for 45 minutes to form a magnetic nanowire magnetic liquid. The magnetic liquid of the magnetically permeable nanowire is injected into the sealing gap of the magnetic liquid.

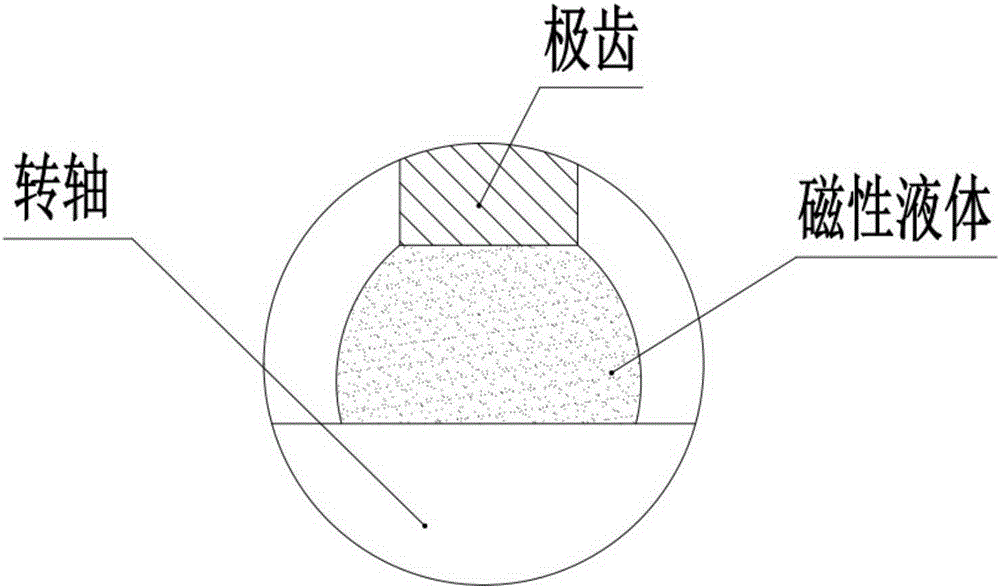

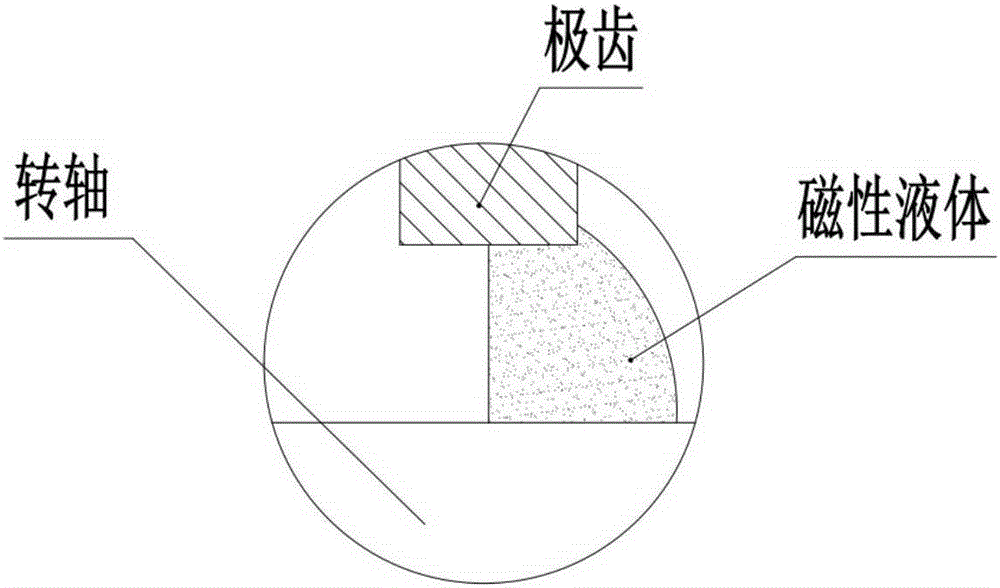

[0017] After using the magnetic nanowire magnetic liquid in the magnetic liquid seal, the nanowires in the magnetic nanowire magnetic liquid between the pole teeth and the rotating shaft will be arranged radially under the action of the magnetic field, as shown in the attached figure 1 , 2 shown. After the side of the seal is pressurized, the permanent magnet will form a certai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com