A suspension carrier system

A technology of suspension and load-carrying devices, which is applied in the field of delivery systems, can solve the problems of the complexity of air traffic management of small domestic aircraft, the inability to popularize ordinary vehicles, and high cost of use, so as to reduce construction costs, low construction costs, and lower requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

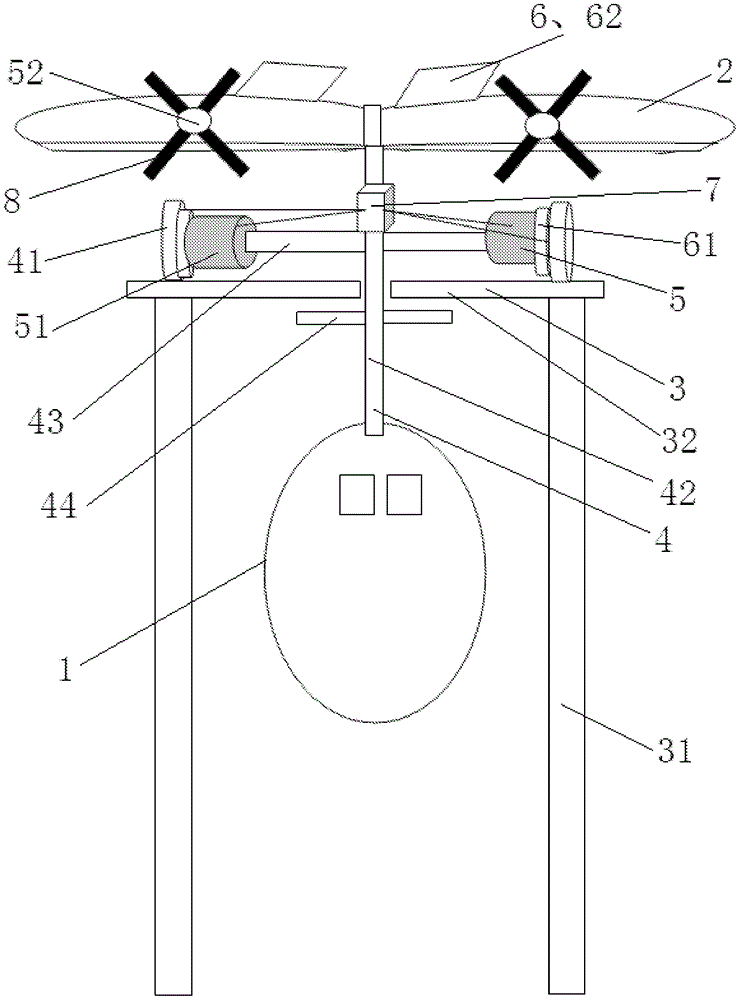

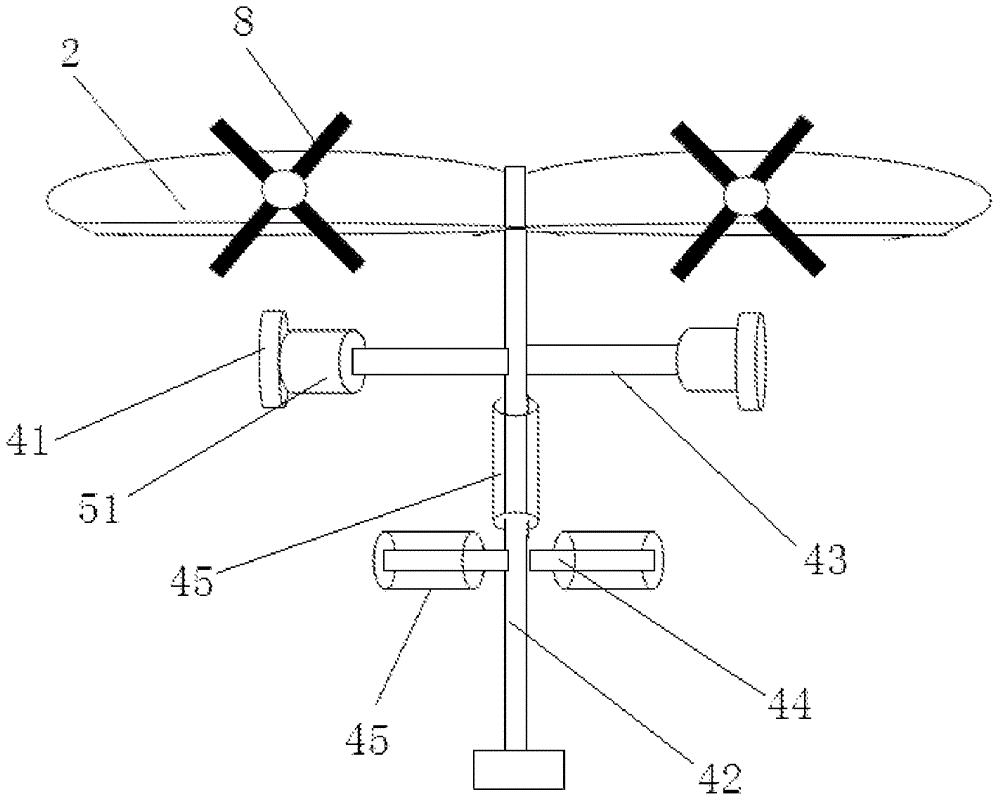

[0049] Such as figure 1 As shown, the running track 3 includes several track supports 31 arranged at intervals along the track running direction, and two pairs of tracks 32 are arranged in parallel at intervals on the track supports 31, and the connecting device 4 includes a vertical shaft 42, and the vertical shaft 42 is located on the two inner rails 32 The upper end of the vertical shaft 42 is connected to the flight wing 2, and the lower end of the vertical shaft 42 is connected to the carrying device 1. At least one wheel shaft 43 is arranged on the vertical shaft 42 between the flying wing 2 and the running track 3, and the two ends of each wheel shaft 43 are respectively connected with a wheel 41 driven by a wheel motor 51, and each wheel 41 is on the two outer rails 32. Operation; a limit rod 44 is arranged on the vertical shaft 42 between the carrying device 1 and the running track 3, and a contact feedback device is arranged between the limit rod 44 and the track 32,...

Embodiment 2

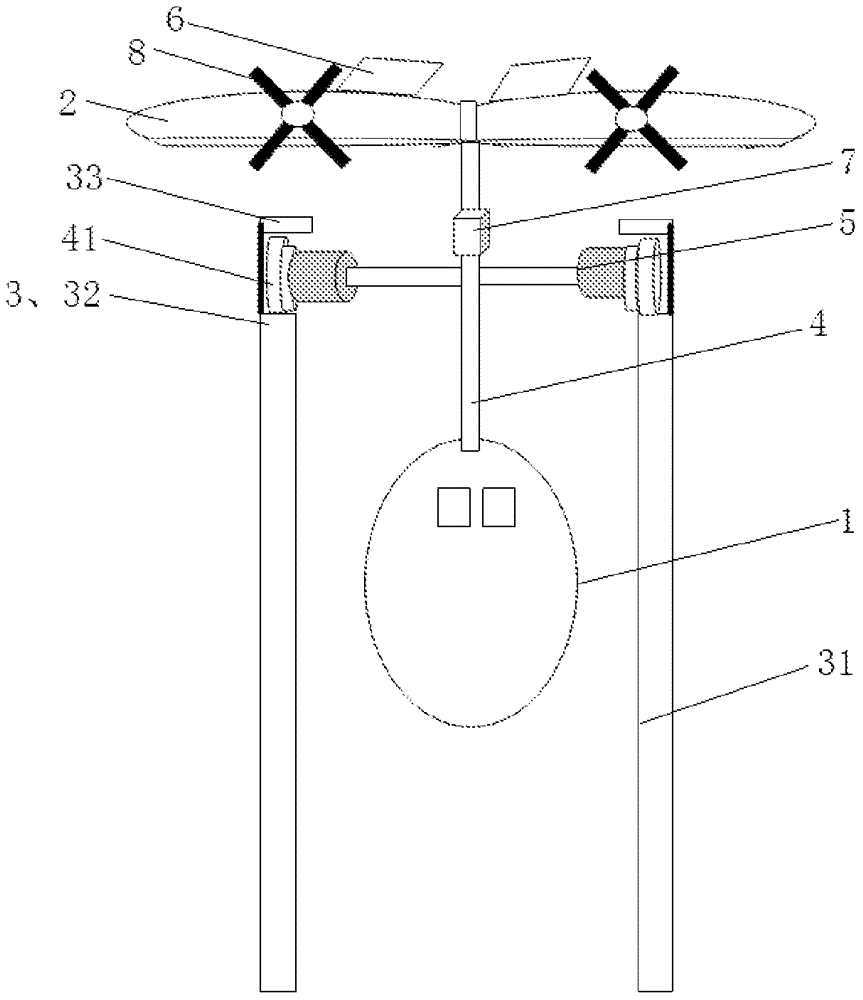

[0053] Such as image 3 As shown, the difference between the present embodiment and the first embodiment is that two rails 32 are arranged in parallel at intervals on the rail bracket 31, and a limiting track 33 is respectively arranged above the two rails 32, and the limiting track 33 and the track 32 Between them is the operating space for limiting the suspension height of the wheels 41. A contact feedback device is provided at the bottom edge of the limit rail 33 to send feedback information to the control device 7, and the control device 7 controls the flying wing 2 to drive the wheels 41 to limit the suspension height. Running in the running space, now it is not necessary to set the limit rod 44.

[0054] When the above-mentioned embodiment is running: after the device of the present invention is installed, start the driving device 5, and the wheel 41 is driven by the wheel motor 51 to rotate, and runs on the track 32. As the speed of the wheel 41 accelerates, the flying ...

Embodiment 3

[0056] Such as Figure 4 As shown, the difference between the present embodiment and the second embodiment is: each track 32 and the limit track 33 above it are oppositely provided with a pair of ribs 34 extending along the running direction of the track 32, and between the two ribs 34 is a limit. The running space of the suspension height of the wheel 41 corresponds to the two convex ribs 34 , a circle of grooves is arranged around the wheel 41 , and the wheel 41 is located in the running space limited by the two convex ribs 34 . A contact feedback device is provided on the bottom rib 34 of the limiting track 33 to send feedback information to the control device 7, and the control device 7 controls the flying wing 2 to drive the wheels 41 to run in the operating space limited by the suspension height.

[0057] When the above-mentioned embodiment is running: after the device of the present invention is installed, start the driving device, and the wheel 41 is driven by the whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com