Mactra veneriformis conditioning accelerator

An acceleration device, a technology of white clams, applied in bivalve processing and other directions, can solve the problems of consuming the physical strength of staff and affecting the taste of dishes, and achieve the effect of reducing labor intensity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

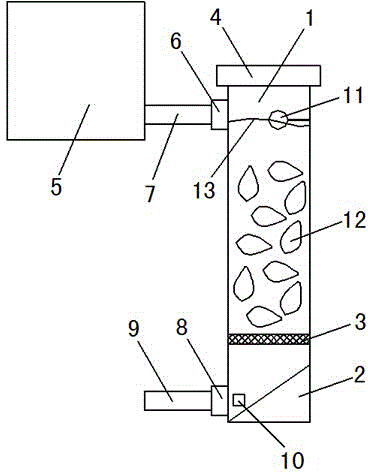

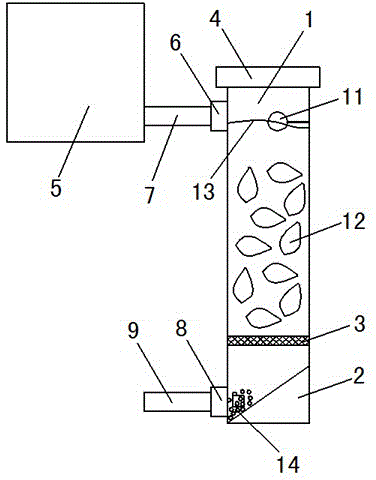

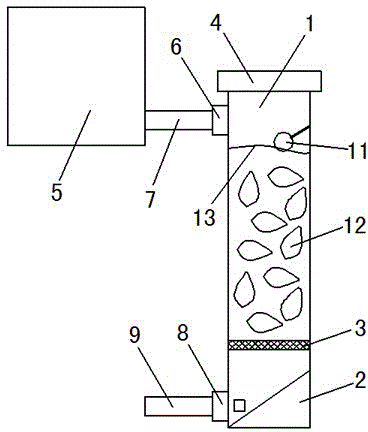

[0019] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0020] The structure of the present invention is as figure 1 As shown, it includes a cuboid container 1, a water storage tank 5, a water injection solenoid valve 6, a water injection pipe 7, a drainage solenoid valve 8, a drain pipe 9, a photoelectric switch 10 and a float switch 11; 3. The bottom of the cuboid container 1 is provided with a slope 2; the photoelectric switch 10 is located at the lower part of the slope 2; the float switch 11 is located at the upper end of the cuboid container 1; one end of the water injection pipe 7 communicates with the water storage tank 5 The other end of the water injection pipe 7 is connected to the upper end of the cuboid container 1 through the water injection solenoid valve 6; the drain pipe 9 is connected to the lower end of the cuboid container 1 through the drain solenoid valve 8; the water injection sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com