Steamed bread bucket

A steamed bun and barrel wall technology, which is applied in the field of steamed bun machine parts, can solve the problems of unsuitable steamed bun barrels, etc., and achieve the effect of excellent taste, material saving, and white, tender and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

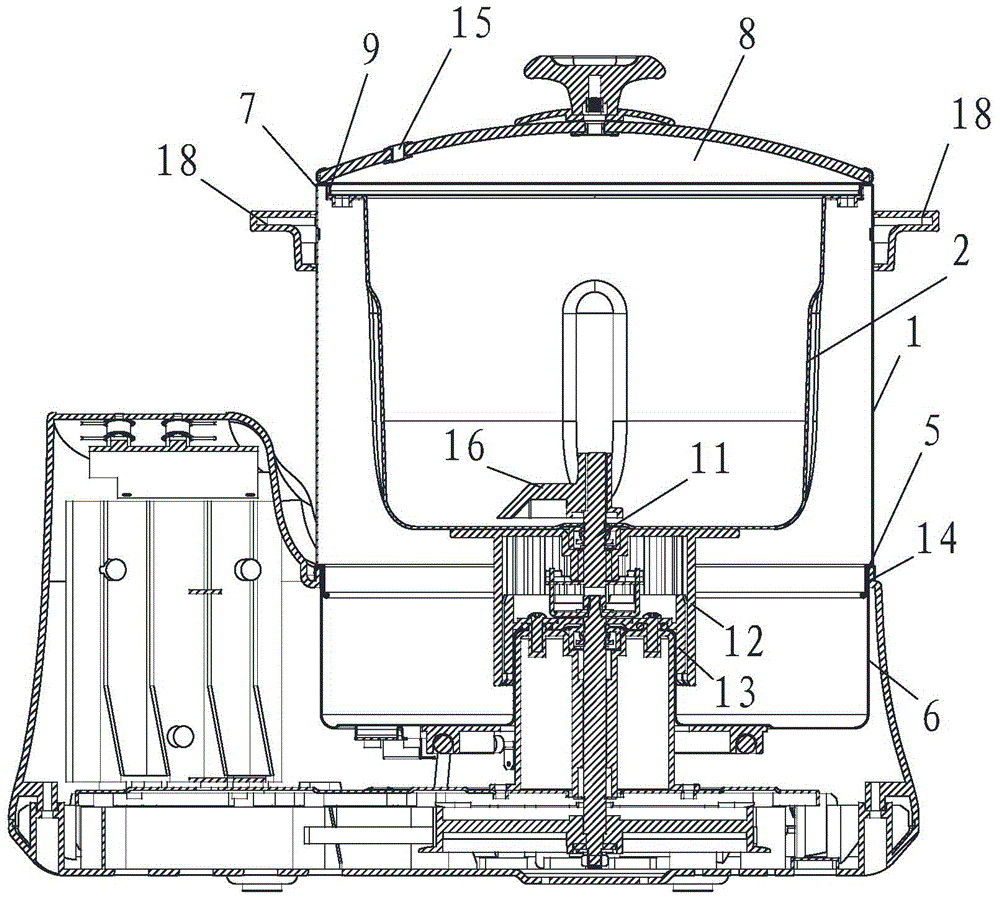

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

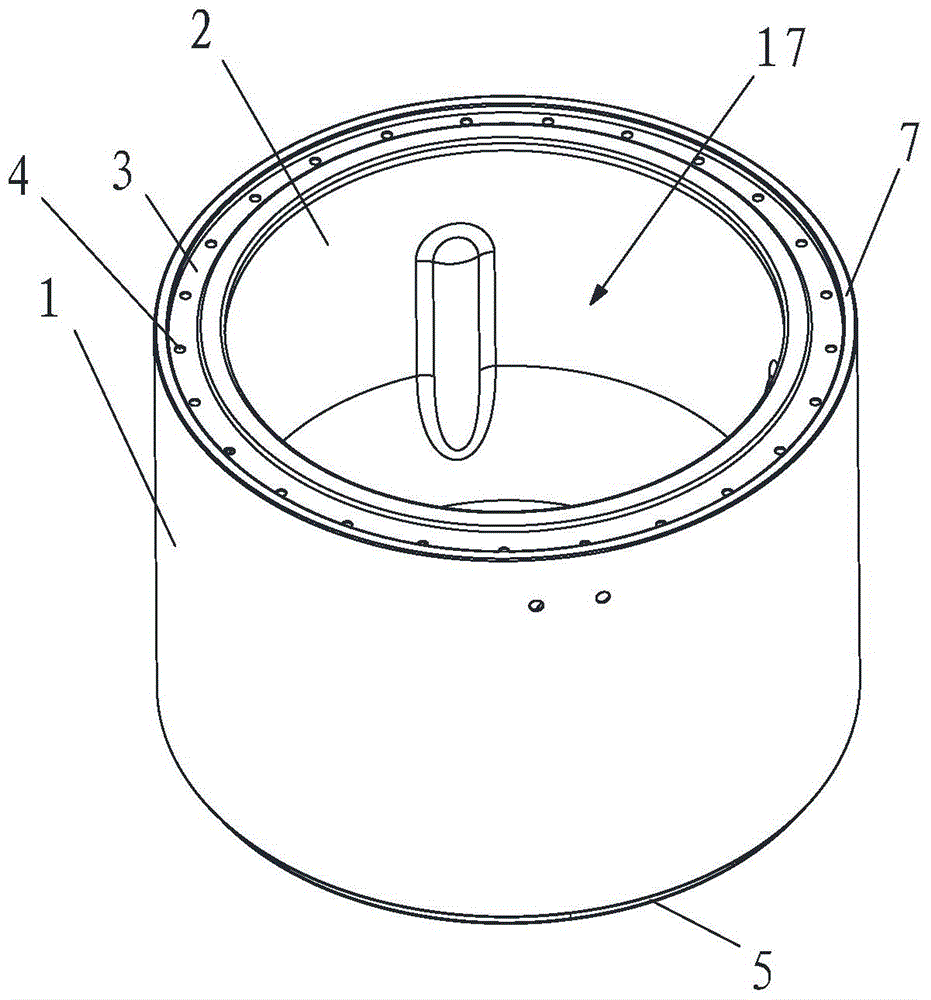

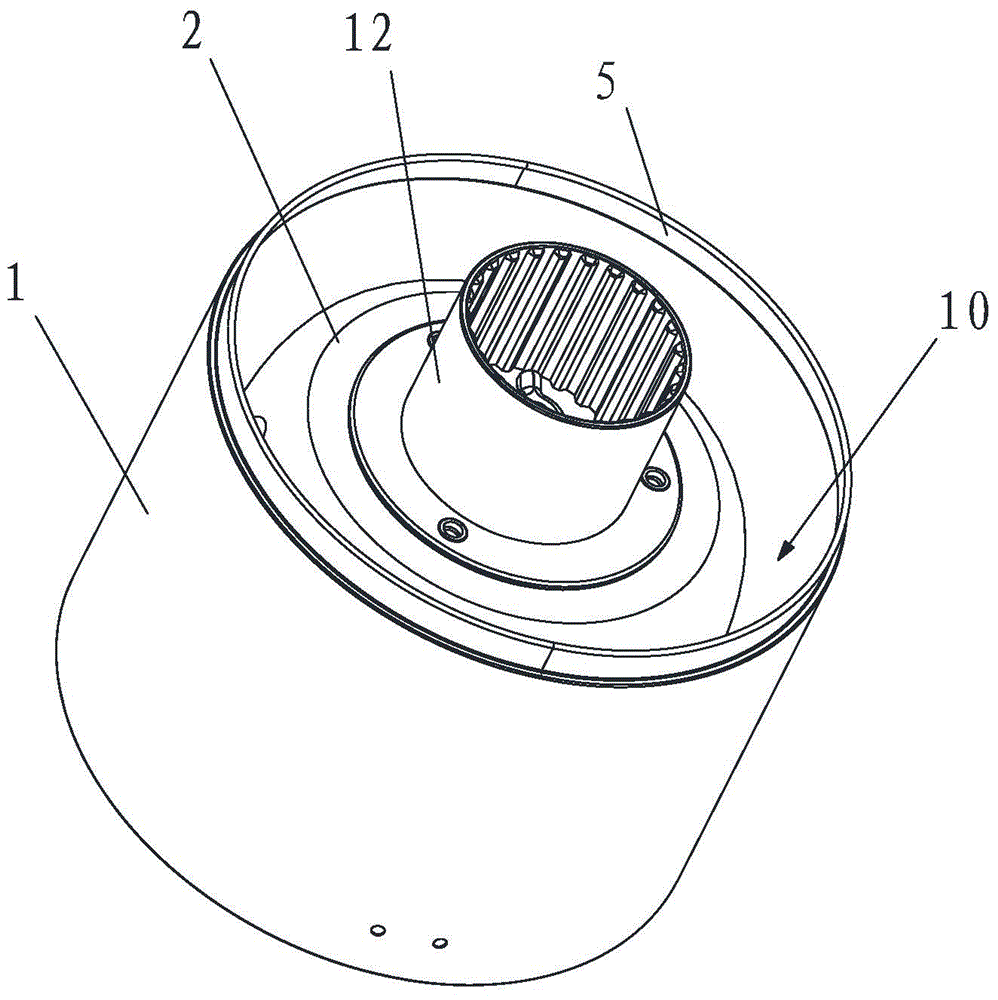

[0018] combine Figure 1 to Figure 3 As shown, a steamed bun barrel has double-layer barrel walls, that is, an outer barrel wall 1 and an inner barrel wall 2 .

[0019] The outer barrel wall 1 is located outside the inner barrel wall 2 , and the upper part of the outer barrel wall 1 is connected with the upper part of the inner barrel wall 2 . Specifically, an annular connecting wall 3 is set between the upper part of the outer barrel wall 1 and the upper part of the inner barrel wall 2, the upper part of the outer barrel wall 1 and the upper part of the inner barrel wall 2 are connected through the annular connecting wall 3, and the A plurality of ventilation holes 4 are evenly arranged on one circumference. The annular connecting side wall 3 is preferably integrally formed with the outer barrel wall 1 and the inner barrel wall 2, which is ea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap