A multi-purpose polylysine fluorescent self-assembled nano-microsphere carrier and its preparation method and application

A technology of polylysine and nano microspheres, which is applied in the field of biomedicine to achieve good colloidal properties, avoid interference, and the effect of simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

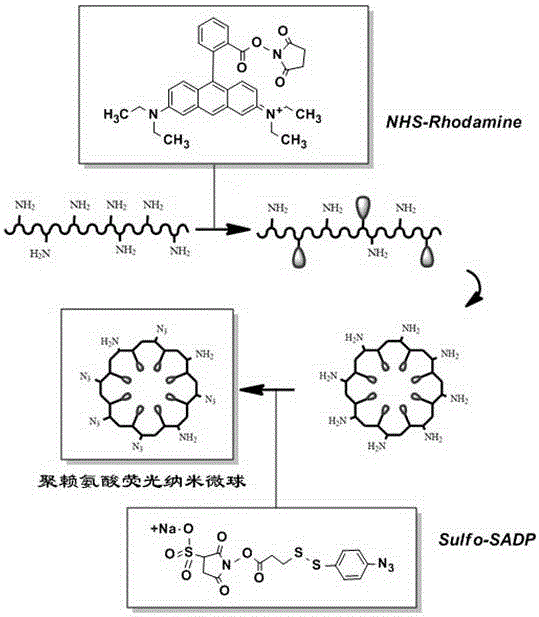

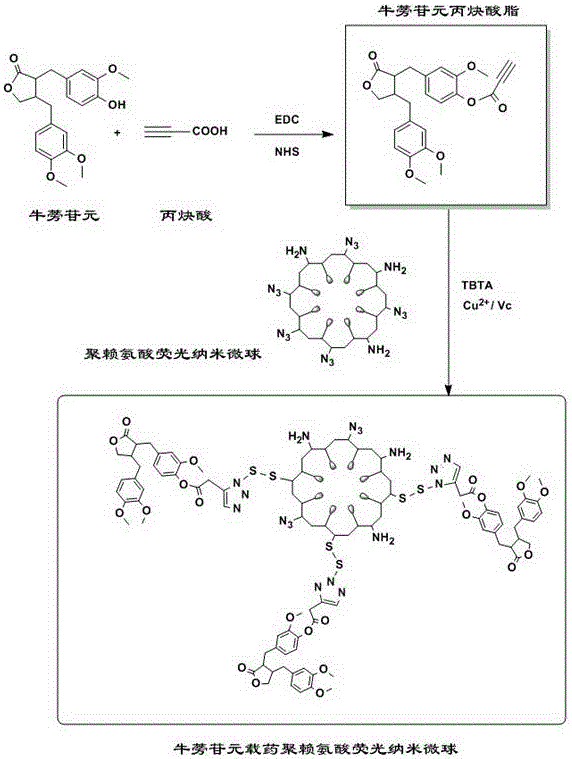

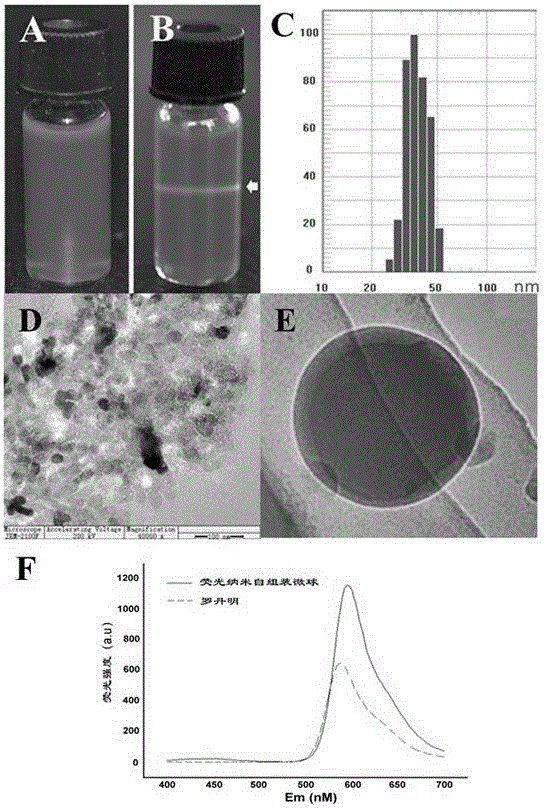

[0034] Example 1. Preparation and azide modification of highly fluorescent polylysine modified nanospheres

[0035] Dissolve 5 g of polylysine hydrochloride in 500 mL of pure water and load it on activated 001×7 cation exchange resin (2×80 cm) for desalting at a rate of 1 mL / min. Equilibrate with 1500 mL of pure water until the effluent is neutral, elute with 5% ammonia water, collect the eluate, distill under reduced pressure, concentrate and dry to obtain 1.9 g of white to light yellow solid.

[0036] Take 200 mg of the above-mentioned desalted polylysine in 10 mL of pure water, stir to dissolve completely to obtain an aqueous phase solution; at the same time, mix 13 mL of gasoline, 12 mL of carbon tetrachloride and 1.25 mL of Span-80, and stir The organic phase is obtained homogeneously. Add 20 mg of NHS-Rhodamine (NHS-Rhodamine, Pierce 46406) to the organic phase, mix well, and set aside. Quickly pour the above water phase into the organic phase, stir at 12,000 rpm for 3...

Embodiment 2

[0038] Example 2, Preparation and Azide Modification of Polylysine Fluorescent Nanospheres

[0039] Dissolve 50 mg of the desalted polylysine in Example 1 above in 10 mL of pure water to obtain an aqueous phase solution; simultaneously mix 5 mL of gasoline, 15 mL of carbon tetrachloride and 0.5 mL of Span-80, and stir evenly to obtain an organic Mutually. Add 0.1 mg of NHS-Rhodamine (NHS-Rhodamine, Pierce 46406) to the organic phase, stir to dissolve, and set aside for later use. Pour the above water phase into the organic phase quickly, stir at 20,000 rpm for 15 seconds at high speed, repeat 3 times to obtain a uniform emulsion, and transfer it to a separatory funnel. Add 20 mL of petroleum ether, stir for 5 minutes, then add 10 mL of pure water, continue stirring for 5 minutes, let stand to separate layers, collect the aqueous phase, and obtain crude fluorescent nanospheres. The crude product was centrifuged at 12,000 rpm for 10 minutes, the precipitate was discarded, and ...

Embodiment 3

[0040] Example 3. Preparation and highly azide modification of polylysine fluorescent nanospheres

[0041] Dissolve 20 mg of the desalted polylysine in Example 1 above in 10 mL of pure water to obtain an aqueous phase solution; at the same time, mix 15 mL of gasoline, 5 mL of carbon tetrachloride and 0.2 mL of Span-80, and stir evenly The organic phase is obtained. Add 2 mg of NHS-Rhodamine (NHS-Rhodamine, Pierce 46406) (0.002 mmoL) to the organic phase, stir to dissolve, and set aside for later use. Pour the above water phase into the organic phase quickly, stir at 10,000 rpm for 20 seconds at high speed, repeat 3 times to obtain a uniform emulsion, and transfer it to a separatory funnel. Add 10 mL of petroleum ether, stir for 5 minutes, then add 10 mL of pure water, continue stirring for 5 minutes, let stand to separate layers, collect the aqueous phase, and obtain crude fluorescent nanospheres. The crude product was centrifuged at 12,000 rpm for 10 minutes, the precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com