A kind of positive electrode material of lithium-sulfur battery and preparation method thereof

A technology for lithium-sulfur batteries and positive plates, which is applied in the field of lithium-sulfur battery positive electrode materials and its preparation, can solve the problems of lithium-sulfur battery positive electrode capacity decline, poor battery cycle life, etc., and achieve improved capacity and cycle performance, low cost, and high energy efficiency. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

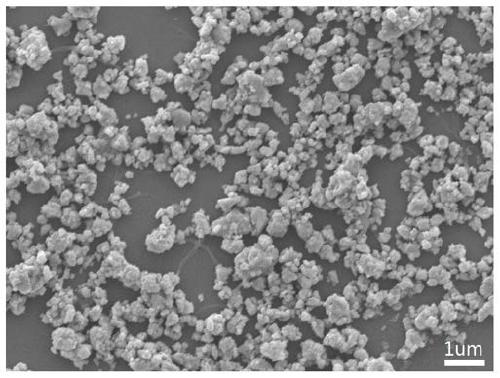

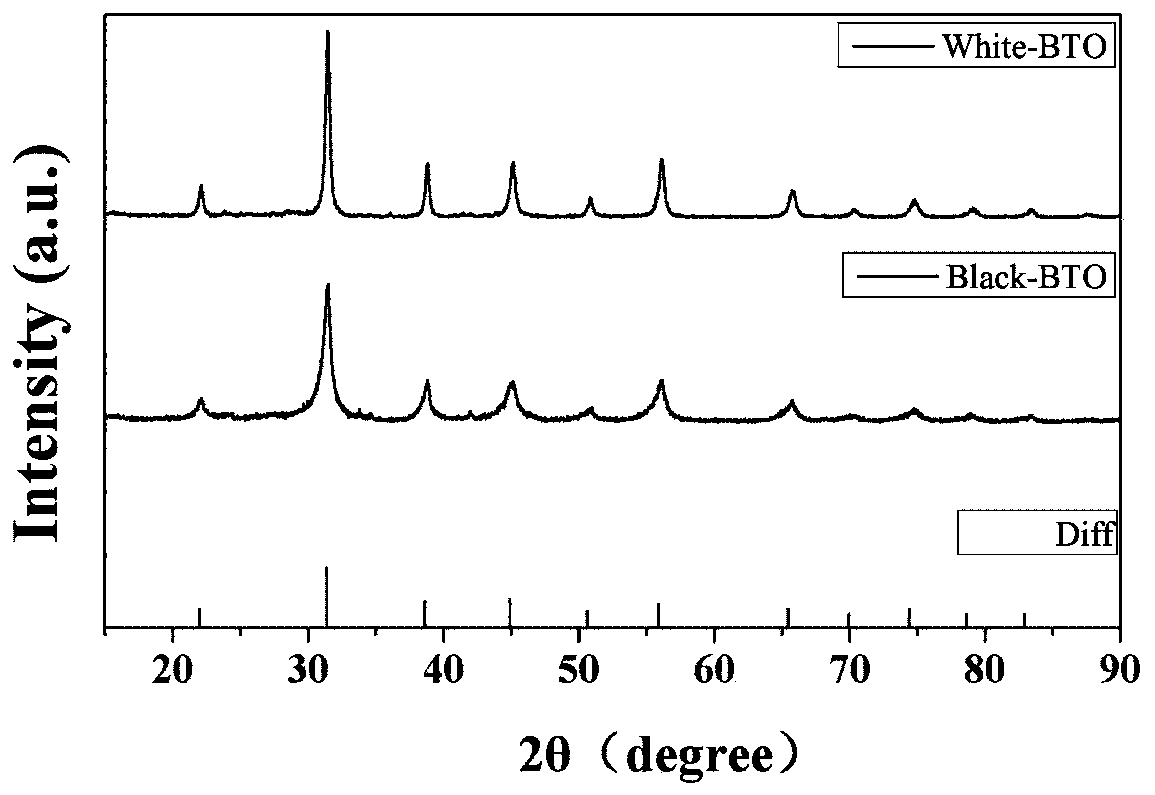

[0034] (1) Preparation of BaTiO 3 powder:

[0035] a) Add barium acetate to 5ml ethylene glycol methyl ether and 2ml glacial acetic acid mixed organic solution and stir, wherein the content of barium acetate is 10-30wt% of the ethylene glycol methyl ether and glacial acetic acid mixed organic solution to obtain solution A ;

[0036] b) by BaTiO 3 In the chemical formula, the molar ratio of Ba and Ti is 1:1, and tetrabutyl titanate is weighed, and tetrabutyl titanate is added into the mixed organic solution of 10ml ethylene glycol methyl ether and 1ml acetylacetone for stirring to obtain solution B;

[0037] c) Weigh 5.40 g of acetic acid, 1.80 g of acetylacetone, 0.81 g of formamide, and 0.81 g of deionized water, and mix and stir for 5 to 15 minutes to obtain solution C. After stirring, pour it into solution A;

[0038] d) Pour solution B into solution A, mix and stir for about 4-6 hours, put it into a drying oven at 60-80°C, after drying, grind it sufficiently, and sinter...

Embodiment 2

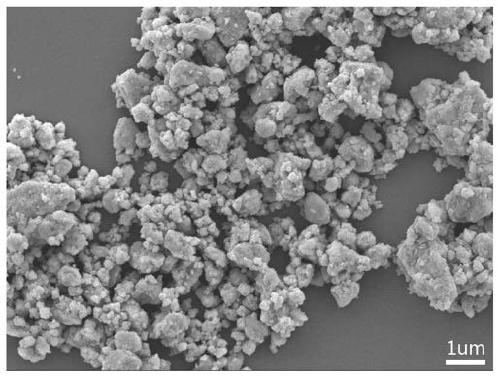

[0052] (1) Preparation of BaTiO 3 powder:

[0053] a) Add barium acetate to 5ml ethylene glycol methyl ether and 3ml glacial acetic acid mixed organic solution and stir, wherein the content of barium acetate is 10-30wt% of the ethylene glycol methyl ether and glacial acetic acid mixed organic solution to obtain solution A ;

[0054] b) by BaTiO 3 In the chemical formula, the molar ratio of Ba and Ti is 1:1, and tetrabutyl titanate is weighed, and tetrabutyl titanate is added into the mixed organic solution of 10ml ethylene glycol methyl ether and 2ml acetylacetone for stirring to obtain solution B;

[0055] c) Weigh 5.40 g of acetic acid, 1.80 g of acetylacetone, 0.81 g of formamide, and 0.81 g of deionized water, and mix and stir for 5 to 15 minutes to obtain solution C. After stirring, pour it into solution A;

[0056] d) Pour solution B into solution A, mix and stir for about 4-6 hours, put it into a drying oven at 60-80°C, after drying, grind it sufficiently, and sinter i...

Embodiment 3

[0070] (1) Preparation of BaTiO 3 powder:

[0071] a) adding barium acetate to 5ml ethylene glycol methyl ether and 4ml glacial acetic acid mixed organic solution and stirring, wherein the content of barium acetate is 10-30wt% of the ethylene glycol methyl ether and glacial acetic acid mixed organic solution to obtain solution A ;

[0072] b) by BaTiO 3 In the chemical formula, the molar ratio of Ba and Ti is 1:1, and tetrabutyl titanate is weighed, and tetrabutyl titanate is added into the mixed organic solution of 10ml ethylene glycol methyl ether and 3ml acetylacetone for stirring to obtain solution B;

[0073] c) Weigh 5.40 g of acetic acid, 1.80 g of acetylacetone, 0.81 g of formamide, and 0.81 g of deionized water, and mix and stir for 5 to 15 minutes to obtain solution C. After stirring, pour it into solution A;

[0074] d) Pour solution B into solution A, mix and stir for about 4-6 hours, put it into a drying oven at 60-80°C, after drying, grind it sufficiently, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com