Reforming catalyst with high dispersion stability and preparation method thereof

A technology of dispersion stability and catalyst, applied in chemical instruments and methods, physical/chemical process catalysts, reformed naphtha, etc., can solve the problems of poor stability of metal active centers of highly dispersed catalysts, and achieve easy industrial application, stable High performance and good reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step A: Mg(NO 3 ) 2 ·6H 2 O, SnCl 4 ·5H 2 O, urea with Mg 2+ :urea:Sn 4+ = The ratio of 3:2:0.02 is dissolved in deionized water, and a certain amount of Al is installed 2 o 3 The reactor was vacuumized, then the above mixed solution was added, and crystallized at 85°C for 5h. Wash by suction filtration, wash with deionized water until neutral, and dry.

[0023] Step B: For the MgAlSn-LDH / Al synthesized in the step (A) 2 o 3 The container was vacuumized and injected with 3.745mL Na 2 PtCl 6 solution (0.046M), let stand for a while, and dry overnight.

[0024] Step C: The catalyst precursor prepared in step (B) is preferably calcined in air at 600°C for 4h (flow rate 80mL / min / g), preferably in 400°C H 2 Reduction for 4h (flow rate 60mL / min / g), heating rate is 10°C / min.

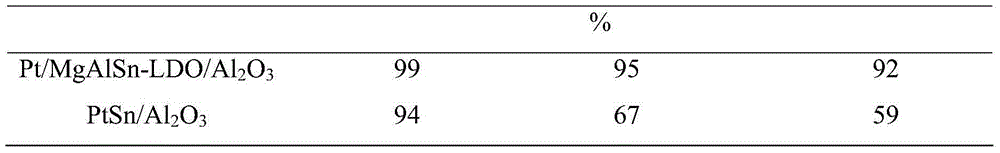

[0025] That is to prepare Pt / MgAlSn-LDO / Al 2 o 3 For the catalyst, the actual loading amount of Pt is 0.30%, and the actual loading amount of Sn is 0.29%.

[0026] According to the X-ray...

Embodiment 2

[0039] Step A: Mg(NO 3 ) 2 ·6H 2 O, SnCl 4 ·5H 2 O, urea with Mg 2+ :urea:Sn 4+ = 3:2:0.01 ratio dissolved in deionized water, for a certain amount of Al 2 o 3 The reactor was vacuumized, then the above mixed solution was added, and crystallized at 85°C for 5h. Wash by suction filtration, wash with deionized water until neutral, and dry.

[0040] Step B: For the MgAlSn-LDH / Al synthesized in the step (A) 2 o 3 The container was vacuumized and injected with 3.74mL Na 2 PtCl 6 solution (0.046M), let stand for a while, and dry overnight.

[0041] Step C: The catalyst precursor prepared in step (B) is preferably calcined in air at 600°C for 4h (flow rate 80mL / min / g), preferably in 400°C H 2 Reduction for 4h (flow rate 60mL / min / g), heating rate is 10°C / min.

[0042] That is to prepare Pt / MgAlSn-LDO / Al 2 o 3 For the catalyst, the actual loading amount of Pt is 0.30%, and the actual loading amount of Sn is 0.15%.

Embodiment 3

[0044] Step A: Mg(NO 3 ) 2 ·6H 2 O, SnCl 4 ·5H 2 O, urea with Mg 2+ :urea:Sn 4+ = 3:2:0.03 ratio dissolved in deionized water, with a certain amount of Al 2 o 3 The reactor was vacuumized, then the above mixed solution was added, and crystallized at 85°C for 5h. Wash by suction filtration, wash with deionized water until neutral, and dry.

[0045] Step B: For the MgAlSn-LDH / Al synthesized in the step (A) 2 o 3 The container was vacuumized and injected with 3.745mL Na 2 PtCl 6 solution (0.046M), let stand for a while, and dry overnight.

[0046] Step C: The catalyst precursor prepared in step (B) is preferably calcined in air at 600°C for 4h (flow rate 80mL / min / g), preferably in 400°C H 2 Reduction for 4h (flow rate 60mL / min / g), heating rate is 10°C / min.

[0047] That is to prepare Pt / MgAlSn-LDO / Al 2 o 3 For the catalyst, the actual loading amount of Pt is 0.30%, and the actual loading amount of Sn is 0.38%.

[0048] The catalysts obtained in Examples 2 and 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com