Method for manufacturing recombined decorative wood with varied texture widths

A technology for recombining decorative wood and manufacturing methods, applied to chemical instruments and methods, manufacturing tools, wood layered products, etc., can solve the problem of high cost and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: a kind of manufacture method of ebony

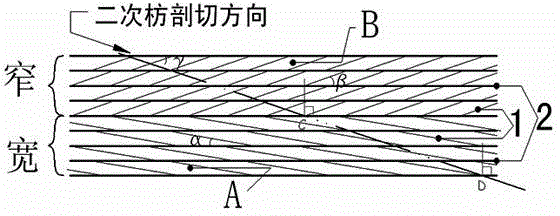

[0020] (1) Black sandalwood is made of veneer of two colors, dark and light, and there are two types of wooden slats, A and B, among which A slats: 1050 sheets / piece, B slats 860 sheets / root; the package is as follows:

[0021] The ratio of the two kinds of wooden squares is the same: 1 1 1 1 2 1 ...Loop until the total number of sheets is allocated.

[0022] The underlined numbers represent the number of dark-colored veneers, and the rest are the number of light-colored veneers.

[0023] (2) Use urea-formaldehyde resin glue, without glue color, and flat die molding. Before pressing, the thickness of the veneer is 0.7-0.85mm; after pressing, the thickness of each veneer is about 0.55mm.

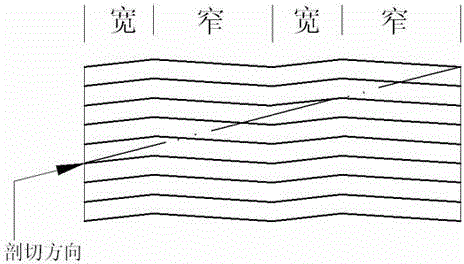

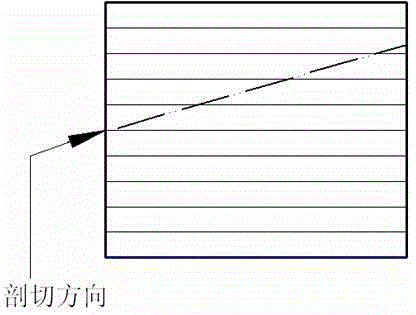

[0024] (3) Fang A does not open the angle, according to the original single-board flat particleboard, sliced to a thickness of 0.7mm, the two colors of the board present random patterns like pancakes; Fang B takes the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com