Floating island precipitation type IBR bioreactor

A bioreactor, biological reaction technology, applied in the direction of aerobic and anaerobic process treatment, can solve the problems of uneven water inflow, increased energy consumption, long aeration pipe and pipeline, etc., to avoid insufficient or excessive aeration Gas, scale adaptability becomes stronger, and the effect of ensuring the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

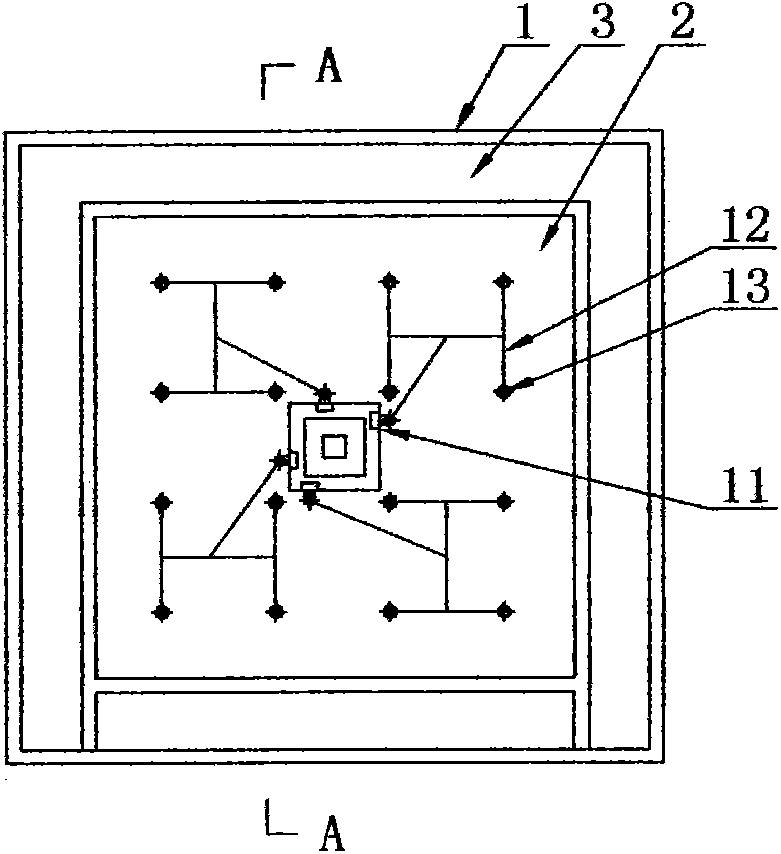

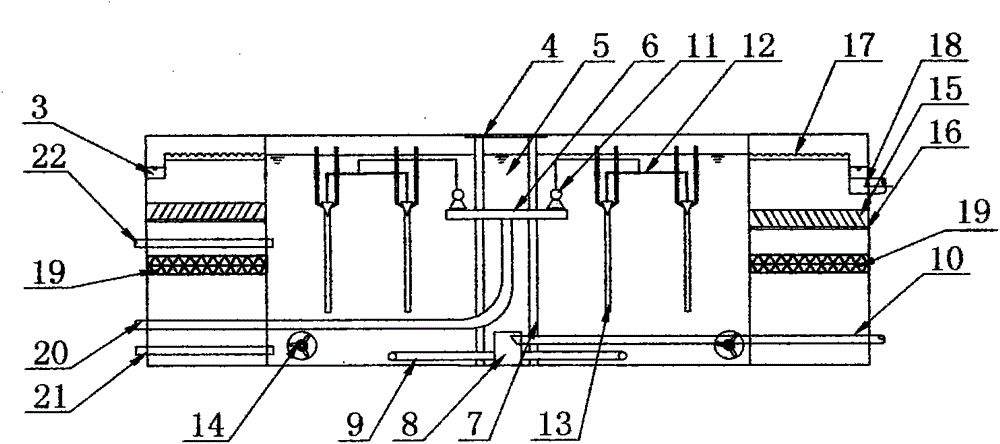

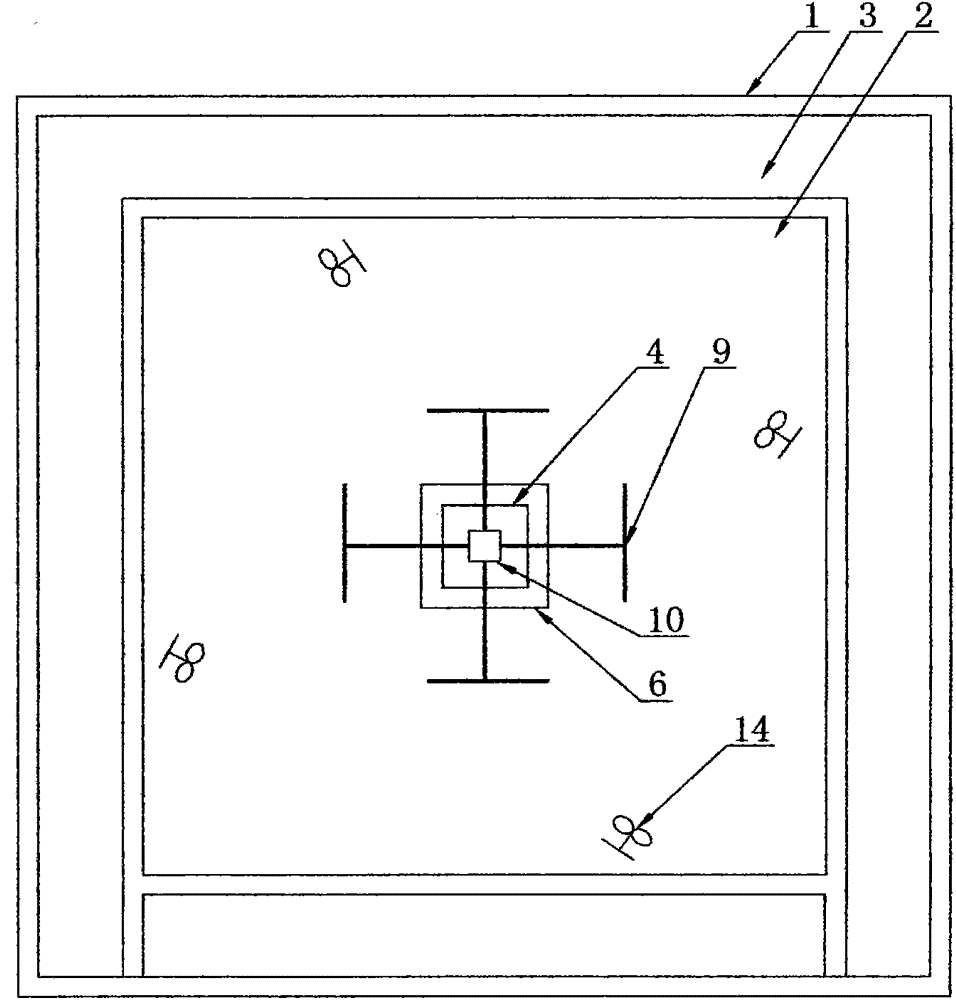

[0020] see Figure 1-Figure 3 , this specific embodiment adopts the following technical scheme: it comprises a reactor 1, a biological reaction zone 2, a sedimentation zone 3, an upper platform 4, a water distribution well 5, an aeration pump platform 6, a support column 7, a closed mud collecting well 8, Radiant T-shaped mud collecting pipe 9, mud discharging pipe 10, submersible sewage pump 11, aeration pipe 12, shock wave mass transfer device 13, submersible mixer 14, honeycomb inclined pipe 15, angle steel 16, triangular weir 17, water outlet pipe 18 , hanging modular three-phase separator 19, water inlet pipe 20, venting pipe 21 and semi-venting pipe 22, a biological reaction zone 2 is arranged in the center of the reactor 1, and a submersible mixer 15 is evenly arranged inside the biological reaction zone 2, and the biological reaction zone 2 is provided with a precipitation zone 3 around, one end of the water inlet pipe 20 is connected with the aeration pump platform 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com