Energy-saving road cutting machine

A cutting machine and sawing technology, applied in the field of energy-saving road cutting machines, can solve the problems of inconvenient charging, short continuous working time, poor working environment for staff and equipment, etc., to prevent sunburn, prolong working time, avoid The effect of direct sun damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

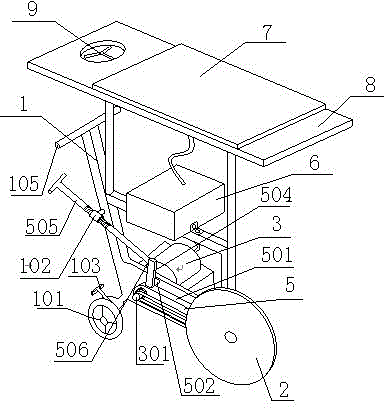

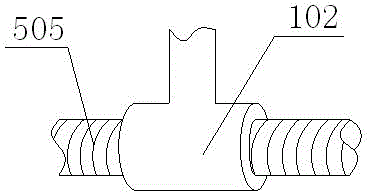

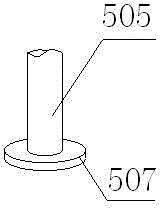

[0028] Such as Figure 1-6 As shown, the energy-saving road cutting machine includes a mounting frame 1, and a cutting saw 2, a motor 3, a battery 6 and a solar panel 7 arranged on the mounting frame 1, and a roller 101 is arranged under the mounting frame 1, and the The cutting saw 2 is installed on the mounting frame 1 through the rotator 5, and the rotator 5 includes a strip-shaped pole 501, and one end of the pole 501 is rotatably mounted on the mounting frame 1 through a pipe fitting 502, and the other A cutting saw 2 is installed at one end, and the pole 501 is aligned with the middle hole of the pipe fitting 502 to be provided with a through hole 503. The rotating shaft 301 of the motor 3 penetrates from the end of the pipe fitting 502 away from the pole 501 and is exposed from the through hole 503. The exposed part of the rotating shaft 301 from the through hole 503 is connected with the belt of the cutting saw 2, and the cutting saw 2 is driven to rotate by the motor ...

Embodiment 2

[0035] Such as Figure 8 , the structure of this embodiment is basically the same as that of Embodiment 1, except that the air inlet of the fan 9 is provided with a filter 10, because the road is generally dusty, and the eyes will be fascinated if you are not careful. It will affect the work efficiency, and it will lead to some accidents in severe cases. Set up a fan and a filter to blow out clean air, so that the environment where the staff is located is relatively clean, not only comfortable to work, but also speeds up the work efficiency.

Embodiment 3

[0037] Such as Figure 9 , the structure of this embodiment is basically the same as that of Embodiment 2, the difference is that a protective stopper 4 is provided at the cutting saw 2 on the pole 501, the protective stopper 4 wraps the cutting saw 2, and the lower end of the protective stopper 4 is open , the cutting saw 2 is exposed at the opening. The protection block 4 one is to prevent debris from splashing upwards and hurt the staff, and the other is to prevent the staff from accidentally touching the cutting saw 2 and causing personal injury.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com