Integral type heavy weight drill pipe without thickening

An integral, drill pipe technology, applied in drill pipes, drill pipes, drilling equipment, etc., can solve the problems of reduced production efficiency, unfavorable forming processing, and little anti-wear effect of anti-wear belts, and achieves high production efficiency and forming. good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

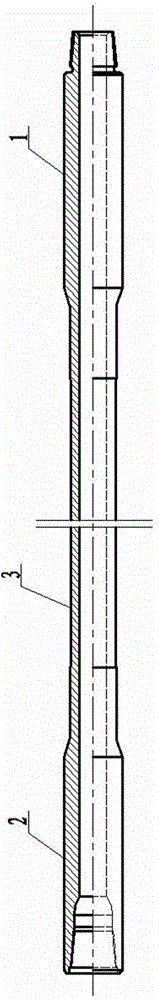

[0012] figure 1 The non-thickened monolithic heavy drill pipe shown is composed of an externally threaded joint 1 , an internally threaded joint 2 and an intermediate pipe body 3 . The external threaded joint 1 and the internal threaded joint 2 have the same outer wall diameter, and the intermediate pipe body 3 located at the waist is an equal-diameter circular tube, and its outer wall diameter is smaller than the outer wall diameter of the external threaded joint 1 or the internal threaded joint 2 located at both ends. This embodiment is a Φ127mm non-thickened integral heavy-duty drill pipe, the outer wall diameters of the external thread joint 1 and the internal thread joint 2 are both Φ168.3mm, and the outer wall diameter of the intermediate pipe body 3 is an equal-diameter circular pipe with a diameter of Φ127mm. The diameter differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com