A kind of medical zinc-based alloy strip and its preparation method

An alloy strip and zinc-based technology, which is applied in the field of medical zinc-based alloy implant device material preparation, can solve the problems of poor comprehensive mechanical properties of as-cast pure zinc, reduce economic burden, improve strength and plasticity, and have poor plastic deformation ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

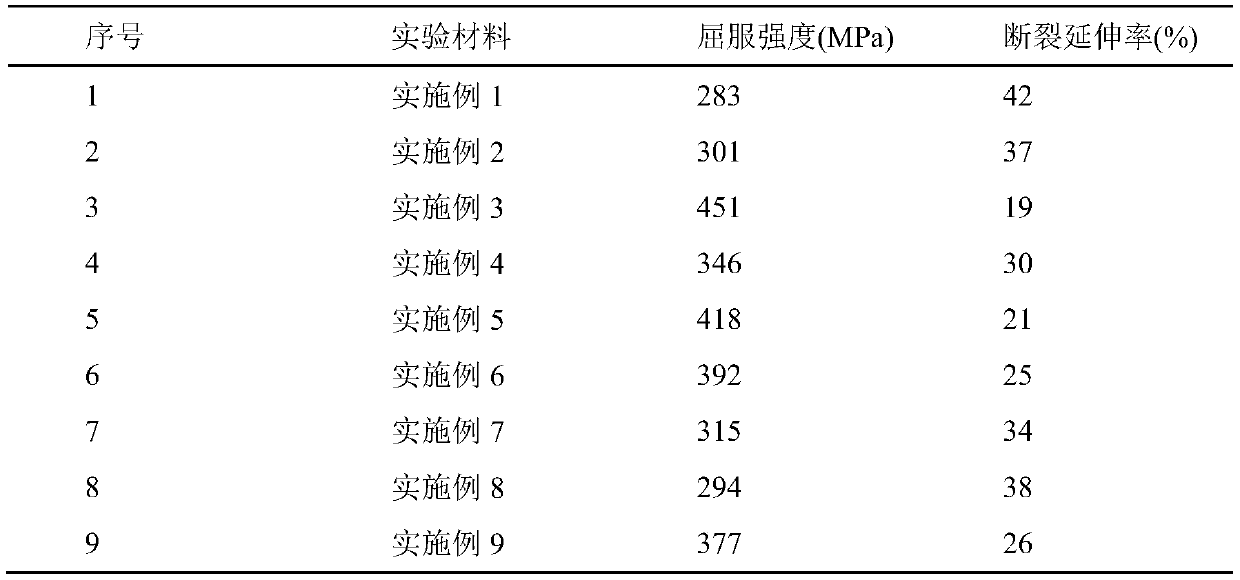

Embodiment 1

[0045] The medical zinc-based alloy strip of the present invention has the following parts by mass of raw materials: 0.2 parts of Mg, 0.05 parts of Li, 0.02 parts of Ca, 0.02 parts of Y, 99.71 parts of Zn and the rest being Zn.

[0046] The preparation steps of the zinc-based alloy strip are as follows:

[0047] step 1,

[0048] (1) take raw material according to above-mentioned alloy ratio;

[0049] (2) After preheating the iron crucible with a protective layer on the inner wall, put metal zinc in it, raise the temperature to 420°C and wait for the pure zinc to completely melt, then raise the temperature of the zinc melt to 620°C, in CO 2 and SF 6 Add metal magnesium, metal calcium, metal lithium, and metal yttrium under the protection of a mixed atmosphere, and stir evenly. After all the metals are melted, let it stand for a while to form an alloy melt, and cool down to 520°C;

[0050] (3) Adding 0.2% of hexachloroethane accounting for the total weight of the alloy melt i...

Embodiment 2

[0060] The medical zinc-based alloy strip of the present invention uses the following mass parts of raw materials: 0.3 parts for Mg, 0.1 parts for Li, 0.1 parts for Ca, 0.05 parts for Y, and 99.45 parts for Zn.

[0061] The preparation steps of the zinc-based alloy strip are as follows:

[0062] step 1,

[0063] (1) take raw material according to above-mentioned alloy ratio;

[0064] (2) After preheating the iron crucible with a protective layer on the inner wall, put metal zinc in it, raise the temperature to 420°C and wait for the pure zinc to completely melt, then raise the temperature of the zinc melt to 620°C, in CO 2 and SF 6 Add metal magnesium, metal calcium, metal lithium, and metal yttrium under the protection of a mixed atmosphere, stir evenly, wait for a period of time to form an alloy melt after all the metals are melted, cool down to 520°C, and cast to obtain an alloy ingot.

[0065] Step 2, Homogenization:

[0066] (1) heat the alloy ingot at 310°C for 24h; ...

Embodiment 3

[0074] The medical zinc-based alloy strip of the present invention has the following mass parts of raw materials: 3 parts of Mg, 1.5 parts of Li, 0.5 parts of Ca, 0.3 parts of Y, and 94.7 parts of Zn.

[0075] The preparation steps of the zinc-based alloy strip are as follows:

[0076] step 1,

[0077] (1) take raw material according to above-mentioned alloy ratio;

[0078] (2) After preheating the iron crucible with a protective layer on the inner wall, put metal zinc in it, raise the temperature to 450°C and wait for the pure zinc to completely melt, then raise the temperature of the zinc melt to 660°C, in CO 2 and SF 6 Add metal magnesium, metal calcium, metal lithium, and metal yttrium under the protection of a mixed atmosphere, and stir evenly. After all the metals are melted, let it stand for a while to form an alloy melt, and cool down to 560°C;

[0079] (3) Add 0.5% hexachloroethane accounting for the total weight of the alloy melt into the alloy melt according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com