Steam turbine generator iron loss test vibration and noise testing method

A steam turbine generator, iron loss test technology, applied in the direction of measuring device, using electric device, using electromagnetic means, etc., can solve problems such as weight, loose stator core end, and large core vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

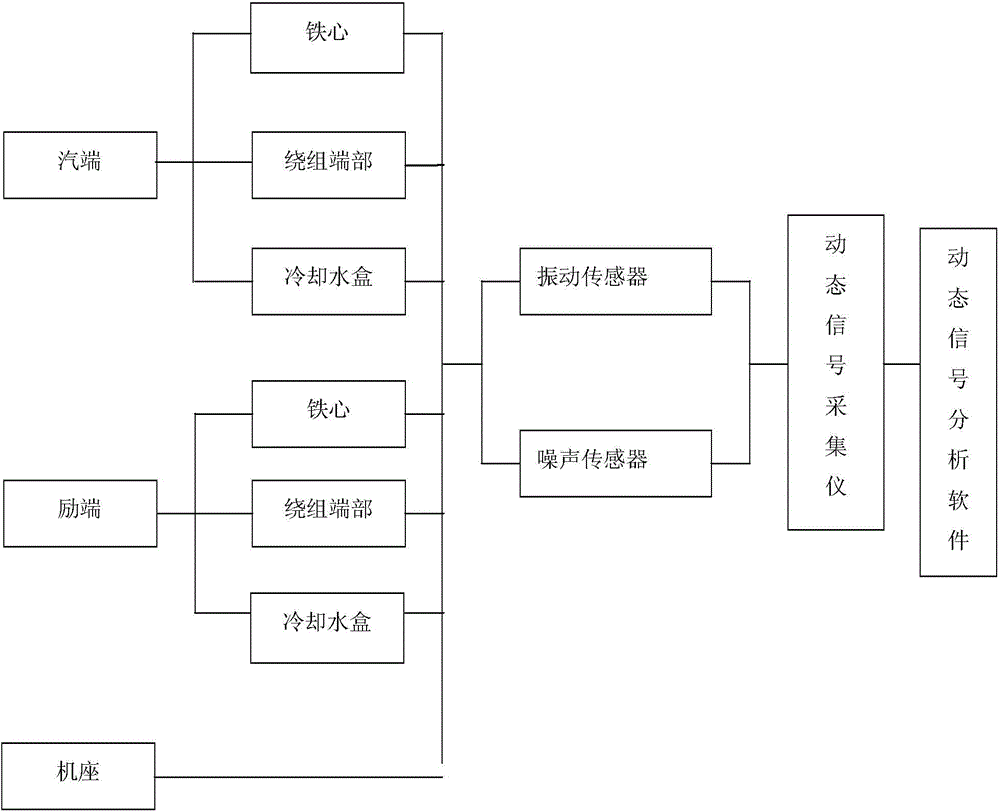

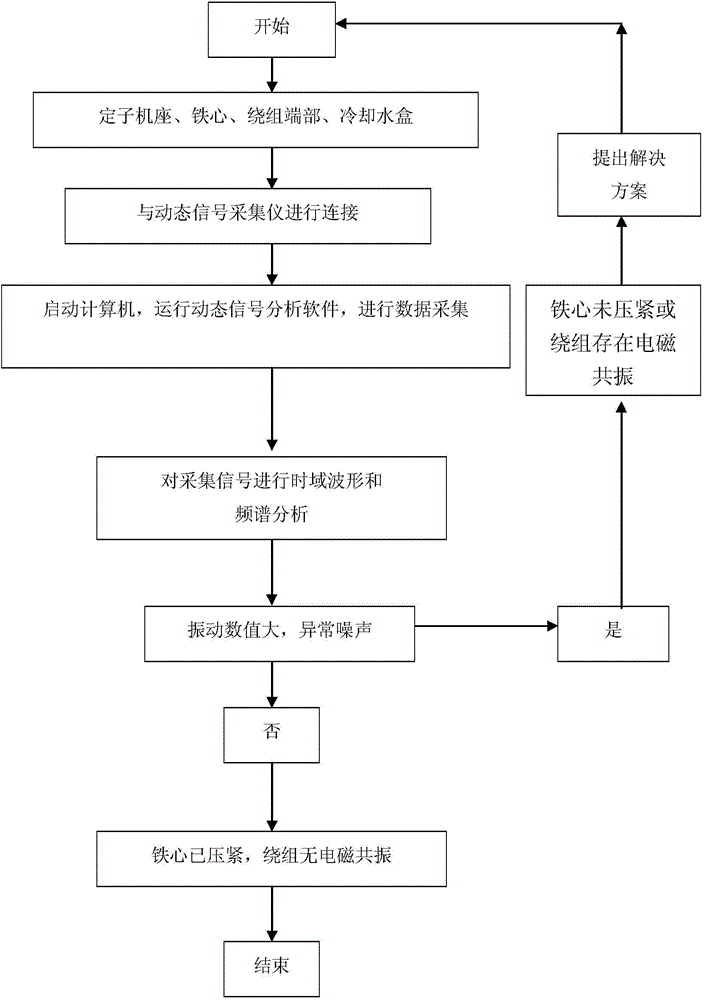

[0011] 1). Acceleration sensors are installed on the turbogenerator stator core pressure plate, core screw, yoke, pressure finger, stator winding water box, and end ring to pick up vibration signals, and install them at a distance of one meter from the steam end and the excitation end. The sound pressure sensor picks up the noise signal, and the vibration sensor adopts the PCB352B piezoelectric acceleration sensor. According to the on-site installation conditions of the iron loss test of the stator core, it is installed at the pressure plate of the excitation end and the steam end of the stator core, the end of the core screw, and the iron core. A PCB352B acceleration sensor is installed in the axial direction of the yoke to measure the axial vibration value of each part, and a PCB352B acceleration sensor is installed in the axial and radial directions of the pressing finger part of the stator core to measure the axial and radial direction of the pressing finger part. Install a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com