High-power high-frequency transformer double-layer oil temperature monitoring system and method thereof

A high-frequency transformer and high-power technology is applied in the field of monitoring systems for monitoring the double-layer oil temperature of high-power high-frequency transformers, which can solve problems such as unsatisfactory adjustment effect, affecting transformer life, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

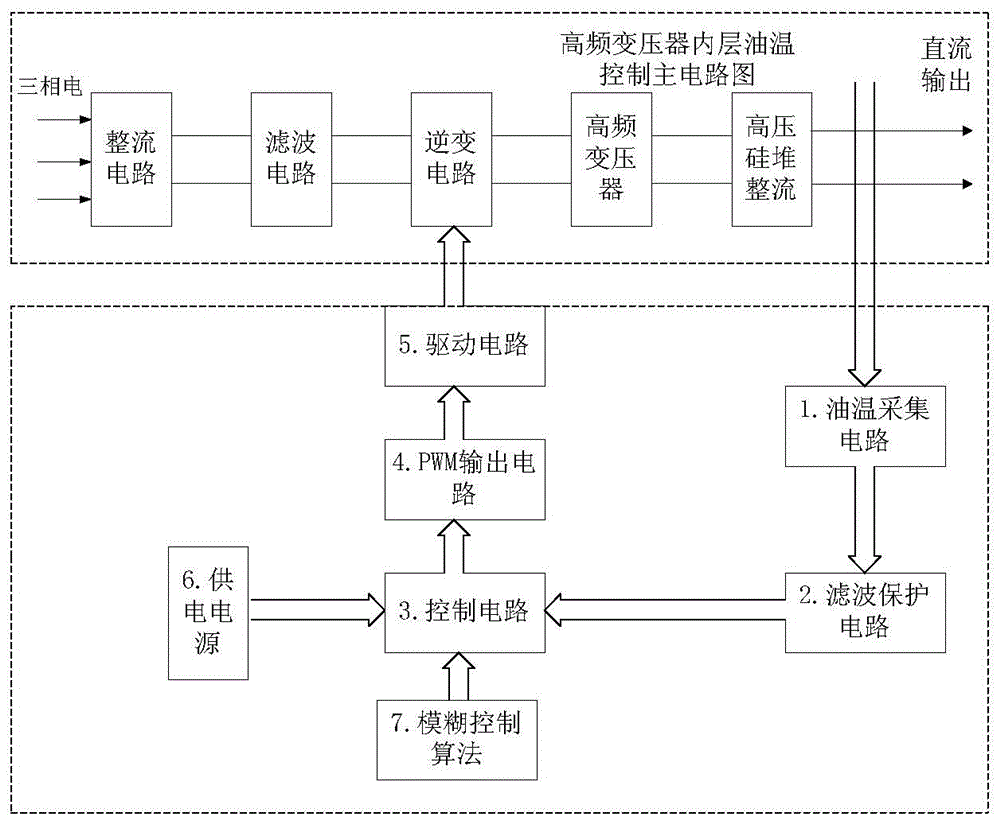

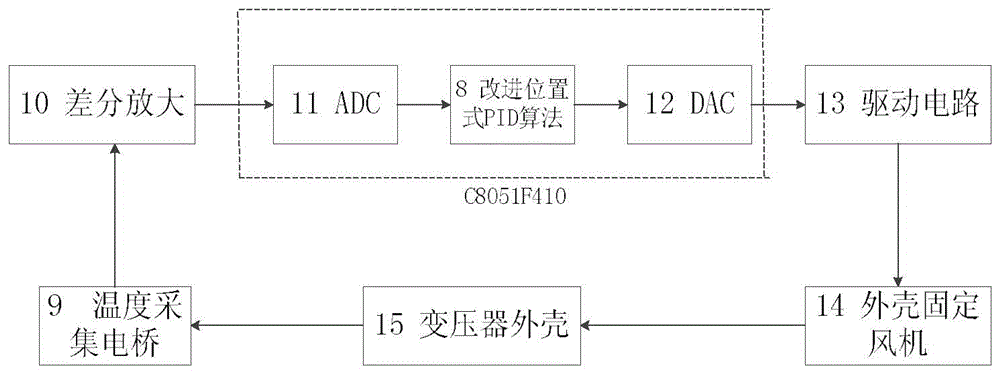

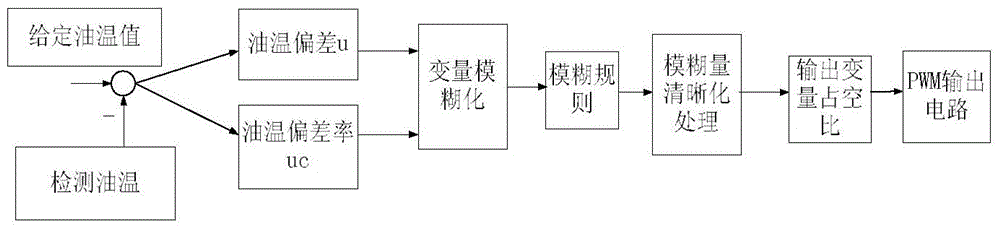

[0048] Such asfigure 1 with figure 2 As shown, the high-power high-frequency transformer double-layer oil temperature monitoring and regulating system of the present invention mainly includes:

[0049] The oil temperature acquisition circuit 1 is used to collect the oil temperature data in the oil-immersed transformer;

[0050] The filter protection circuit 2 is used to receive the data from the oil temperature acquisition circuit and send it to the control circuit after processing;

[0051] The control circuit 3 is used to receive the signal of the filter protection circuit and convert it into a digital quantity, and compare the digital quantity with a preset value, for example, to determine whether the temperature is too high;

[0052] The PWM wave output circuit 4 is connected to the output port of the control circuit, and when the temperature is higher than the preset value, the PWM wave of the expected duty ratio is output through it;

[0053] The drive circuit 5 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com