CCD signal acquisition device and method

A technology of signal acquisition and collection method, applied in conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problems of inability to store picture information, low work efficiency, inconvenient inspection and comparison, etc., to achieve information storage Large volume, improve work efficiency, facilitate comparison and check the effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

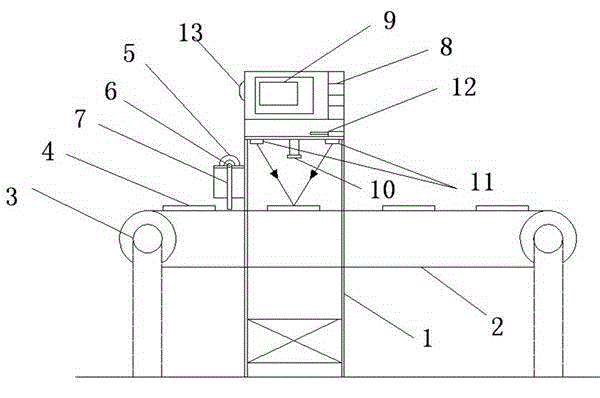

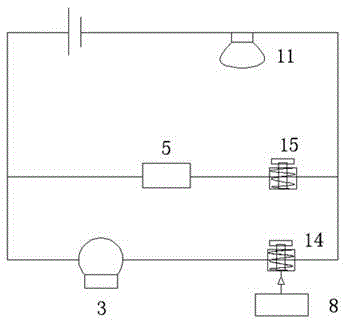

[0023] Example 1: like figure 1 and 2 Shown a kind of CCD signal acquisition device, described CCD signal acquisition device is fixedly installed on the belt transmission line 2 directly above by fixed support 1, and described CCD signal acquisition device comprises lens detection station and detection buffering station for material, so The subject lens detection station comprises imaging lens 10, lighting spotlight 11, LED display screen 9, detection control computer 8 and wireless barcode scanning gun 12; Described detection buffering material waiting station comprises micro frequency conversion motor 5, transmission shaft 6 and stop material plate 7, the material blocking plate 7 is arranged at the feed end of the lens inspection station, and the micro frequency conversion motor 5 is connected in series with the lighting spotlight 11 on an integral circuit through the switch electromagnetic control valve 15,

Embodiment 2

[0024] Example 2: like figure 1 and 2 As shown, the belt transmission line 2 of the present invention is connected to the frequency conversion transmission motor 3 through the rotating shaft, and the frequency conversion transmission motor 3 is controlled by the transmission solenoid valve 14, and the transmission solenoid valve 14 is connected to the detection control computer via a line 8; through the detection control computer 8 to control the switch of the frequency conversion drive motor 3, the signal acquisition work of the lens detection station on the belt transmission line 2 is convenient, and the operation is convenient to start and shut down.

Embodiment 3

[0025] Example 3: like figure 1 As shown, the detection and control computer 8 of the present invention is provided with a warning light 13; since the present invention is an automatic signal acquisition device, unnecessary manual operation is not required, and when the equipment breaks down in the signal collection process, it will be reminded in time by the warning light Staff, reduce the error rate in the equipment scanning process, and improve the overall work efficiency of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com