High-precision controllable nozzle gas pool

A high-precision, nozzle technology, used in electrical components, accelerators, etc., to improve work efficiency, save costs, good stability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

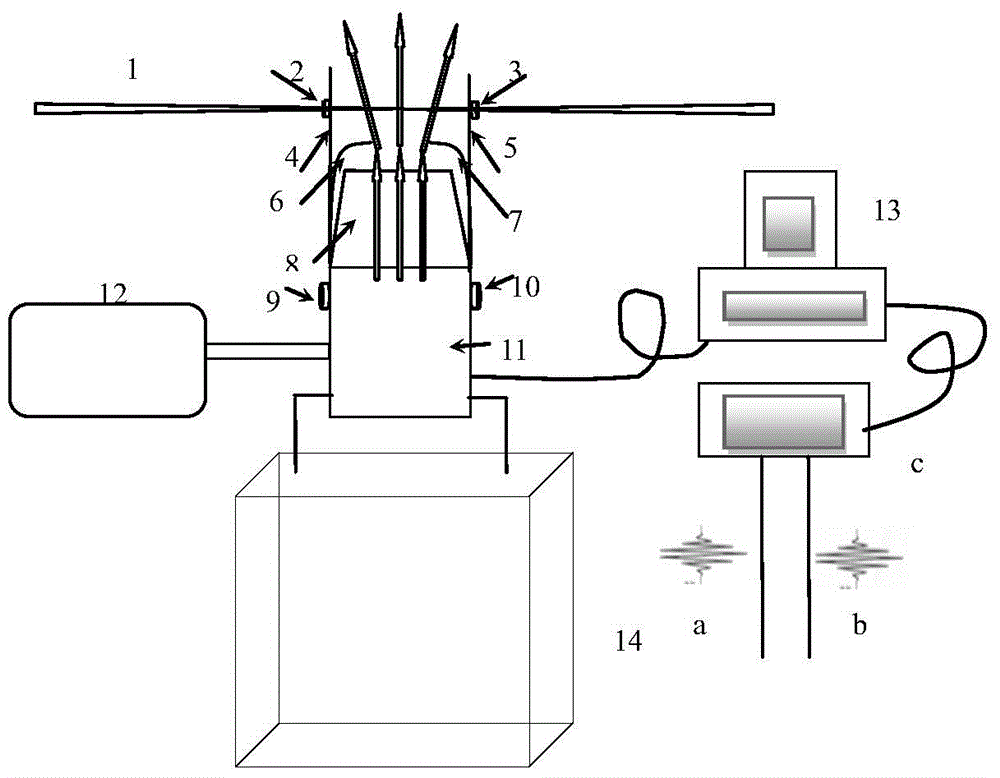

[0026] see first figure 1 , figure 1 It is a structural schematic diagram of the high-precision controllable nozzle gas pool of the present invention. As can be seen from the figure, the structure of the high-precision controllable nozzle gas pool of the present invention is that a supersonic gas valve 11 is fixed on a mobile adjustment platform 14 with front, rear, left, right, and 360-degree rotation, and the upper end of the supersonic gas valve 11 The outer thread of the outer thread is linked with the inner thread of a prolate oval spout 8, and the periphery of the prolate oval spout 8 has two screw holes for screwing in and fixing two flat head hexagon socket screws 9, 10; The both sides of prolate oval spout 8 are respectively provided with vertically upward front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com