Transmission system of a cross-flow multi-drum combine harvester

A technology of combine harvester and transmission system, applied in the field of transmission system, can solve the problems of increased manufacturing cost, increased transition transmission, long transmission distance, etc., and achieves the effects of improving work efficiency, reducing power loss and reasonable transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

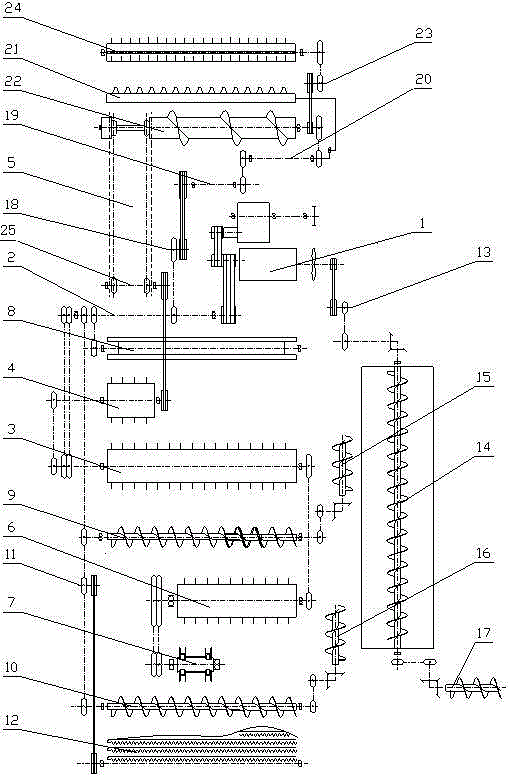

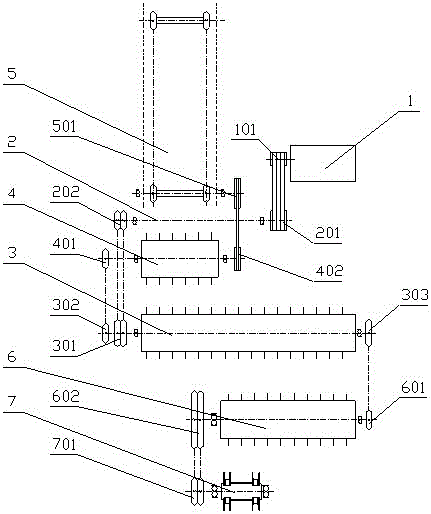

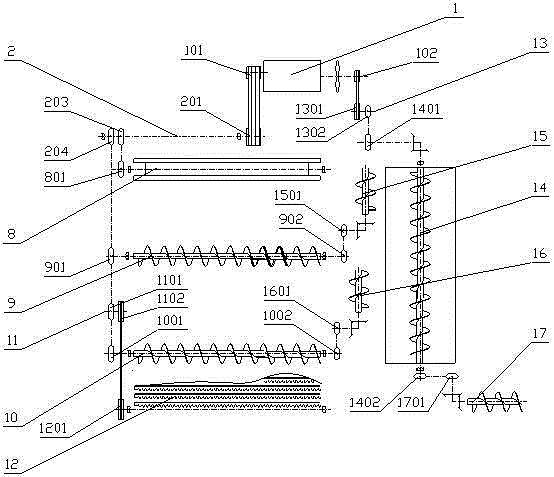

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0023] like figure 1 As shown, the transmission system of the cross-cutting flow multi-drum combine harvester of the present invention divides the transmission system of the whole combine harvester into three parts by the power distribution effect of the intermediate shaft 2.

[0024] The first part is the power distribution system of the first horizontal axial flow drum 3, the cutting flow drum 4, the conveying trough 5, the second horizontal axial flow drum 6 and the grass cutting drum 7; the second part is the fan 8 and the horizontal grain conveying auger 9 , horizontal miscellaneous auger 10, transition tensioning device 11, vibrating screen 12, grain unloading transition device 13, horizontal grain unloading auger 14, grain lifting auger 15, miscellaneous lifting au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com