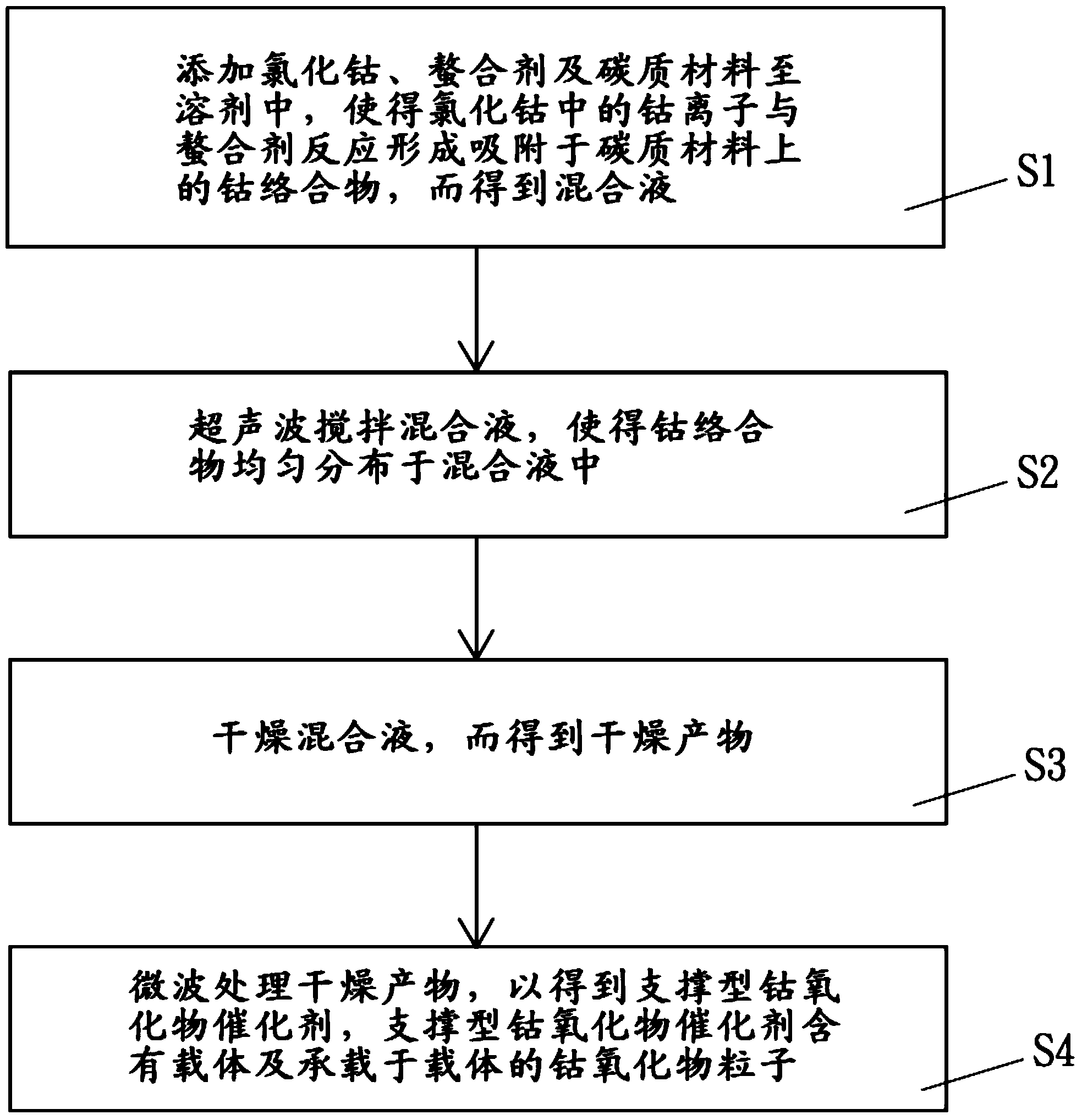

Method for preparing support-type cobalt oxide catalyst

A manufacturing method and technology of cobalt oxide, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of uneven catalyst particle size, lengthy manufacturing process, Unable to reduce fuel cell manufacturing costs and other issues, to achieve the effect of easy operation and lower manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

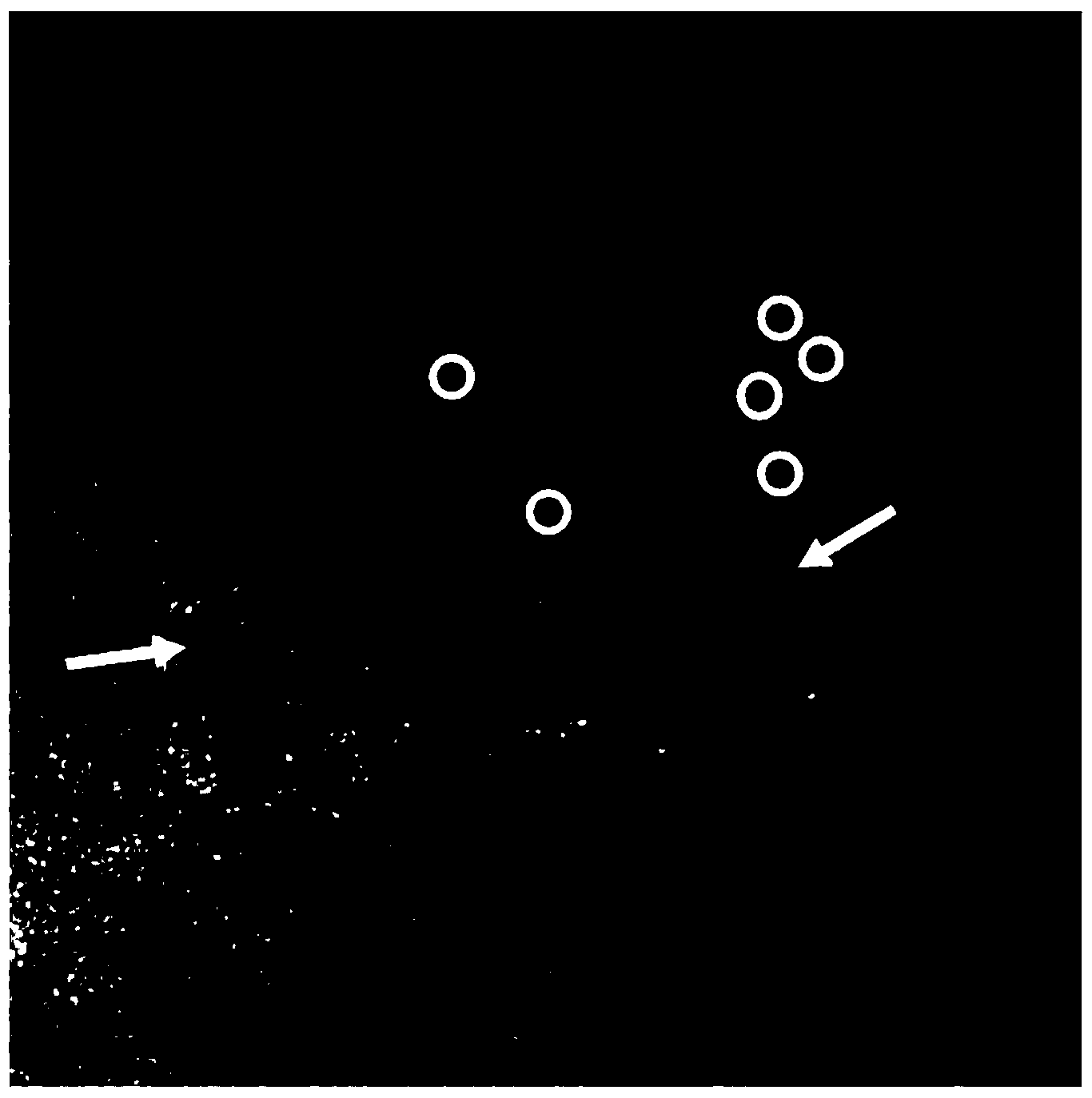

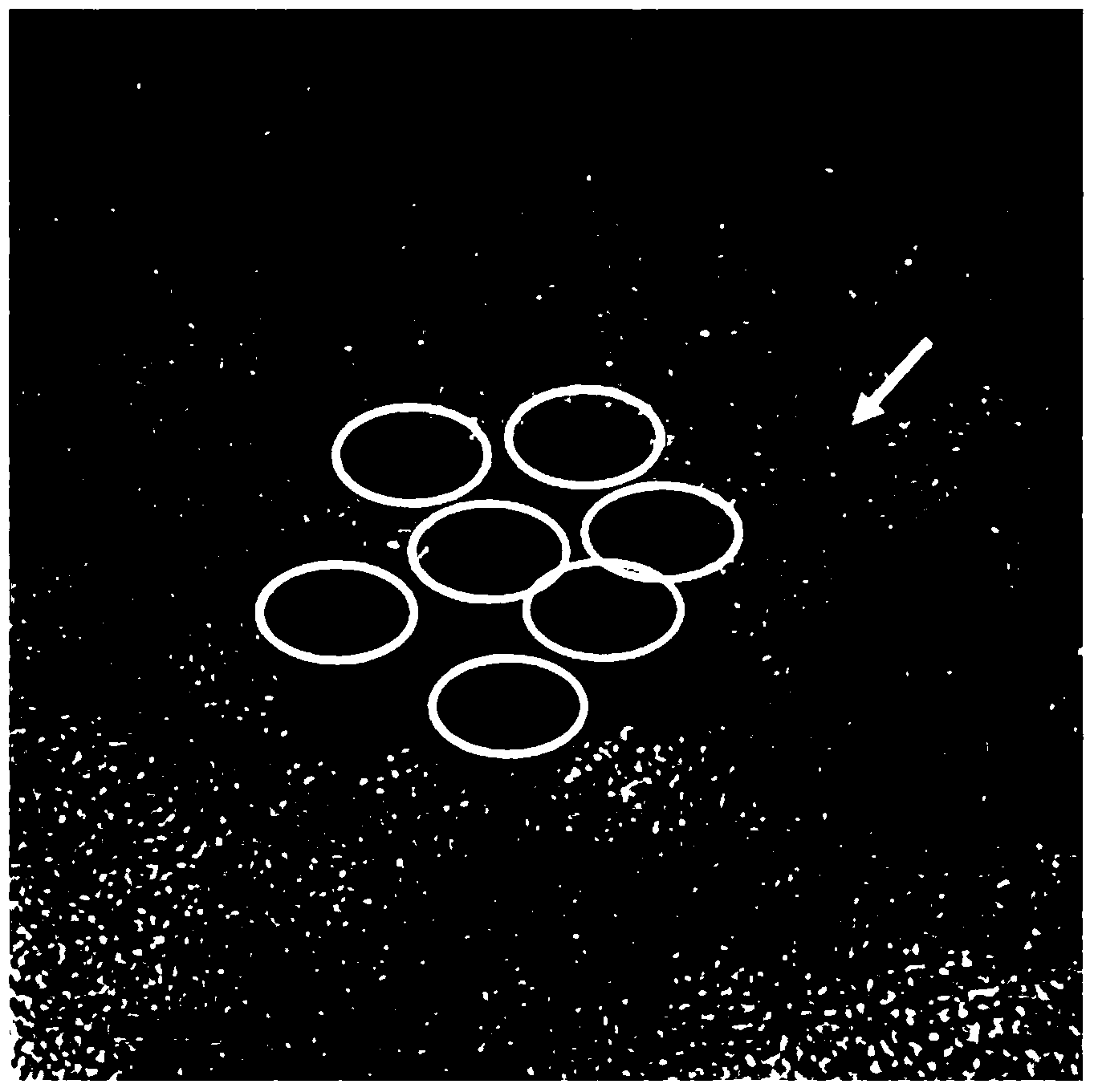

[0043] First, while stirring the aqueous ethanol solution (the volume ratio of ethanol and water is 1:1), add 0.22mmol of cobalt chloride hexahydrate and 0.22mmol of ethylenediamine to the aqueous solution to allow the cobalt ions and ethylenediamine to react to form Expressed as [Co(en) 1 (H 2 O) 4 ] 3+ of cobalt complexes. Add 450 mg of Vulcan XC-72 carbon black to the aqueous solution to allow the carbon black to adsorb the cobalt complex, and the weight ratio of cobalt ions adsorbed on the carbon black to the carbon black is about 2%. Next, ultrasonically treat the obtained mixed solution for 24 hours, so that the cobalt complex in the mixed solution is uniformly distributed therein. The mixed solution is placed in a dehydrator, and the mixed solution is dehydrated by the dehydrator in a vacuum environment, and the aqueous solution in the mixed solution is removed to obtain a dry product. Finally, the product was dried by microwave treatment with an output power of 2,...

preparation example 2

[0046] First, while stirring the aqueous ethanol solution (the volume ratio of ethanol and water is 1:1), add 0.22mmol of cobalt chloride hexahydrate and 0.22mmol of diethylenetriamine to the aqueous solution to allow cobalt ions and diethylenetriamine The reaction forms expressed as [Co(DETA) 1 (H 2 O) 3 ] 3+ of cobalt complexes. Add 450 mg of Vulcan XC-72 carbon black to the aqueous solution to allow the carbon black to adsorb the cobalt complex, and the weight ratio of cobalt ions adsorbed on the carbon black to the carbon black is about 2%. Next, ultrasonically treat the obtained mixed solution for 24 hours, so that the cobalt complex in the mixed solution is uniformly distributed therein. The mixed solution is placed in a dehydrator, and the mixed solution is dehydrated by the dehydrator in a vacuum environment, and the aqueous solution in the mixed solution is removed to obtain a dry product. Finally, the product was dried by microwave treatment with an output power...

preparation example 3

[0049] First, while stirring the aqueous ethanol solution (the volume ratio of ethanol and water is 1:1), add 0.22mmol of cobalt chloride hexahydrate and 0.22mmol of porphyrin to the aqueous solution, allowing cobalt ions and porphyrin to react to form [Co(pP) 1 (H 2 O) 2 ] 3+ of cobalt complexes. Add 450 mg of Vulcan XC-72 carbon black to the aqueous solution to allow the carbon black to adsorb the cobalt complex, and the weight ratio of cobalt ions adsorbed on the carbon black to the carbon black is about 2%. Next, ultrasonically treat the obtained mixed solution for 24 hours, so that the cobalt complex in the mixed solution is uniformly distributed therein. The mixed solution is placed in a dehydrator, and the mixed solution is dehydrated by the dehydrator in a vacuum environment, and the aqueous solution in the mixed solution is removed to obtain a dry product. Finally, the product was dried by microwave treatment with an output power of 2,500 W for 10 minutes to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com