Metal separation device special for PET bottle grades

A technology of metal separation and bottle flakes, which is applied in the direction of solid separation, magnetic separation, recycling technology, etc., to avoid incomplete separation and improve the detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

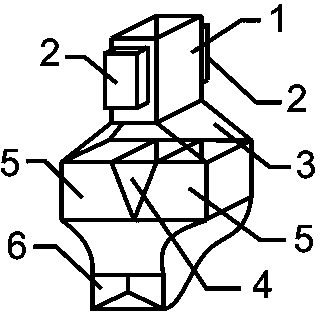

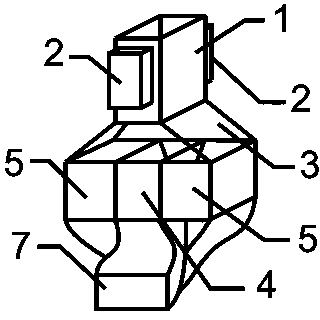

[0013] Special metal separation device for PET bottle flakes, including feed inlet 1, magnet 2, transparent connecting belt 3, impurity channel 4, PET bottle flake channel 5, PET bottle flake outlet 6, and impurity outlet 7. It is characterized in that the impurity channel 4 is set on In the middle of the two PET bottle flake channels 5, the feed port 1 is set directly above the PET bottle flake channel 5 and the impurity channel 4 arranged side by side, and the transparent The connection belt 3 is connected, the magnet 2 is set in the front and rear directions of the feed port 1, the impurity channel 4, the PET bottle flake channel 5, and the feed port 1 have the same length, and the lower ends of the two PET bottle flake channels 5 are merged and connected on one side. On the PET bottle flake outlet 6, the impurity channel 4 is connected to the impurity outlet 7 on the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com