Automatic welding and cooling device and welding method

An automatic welding and cooling device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to weld, difficult to weld thin-walled pipes, etc., to reduce heat input, reduce high temperature residence time, and reduce growing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1. The method of the present invention is mainly to insert an automatic welding cooling device containing circulating cooling water into the inside of the pipe when welding the pipe, so that the high temperature generated by welding on the outer wall of the pipe is conducted to the automatic welding cooling device through the pipe wall, and then The heat is taken away by the circulating cooling water, so as to achieve the purpose of rapidly cooling the pipe welding place while welding, which can ensure that the pipe will not be deformed or melted due to the high temperature of the welding place during welding, which will affect the welding effect. Wall pipes are generally difficult to weld or even impossible to weld. The thin-walled pipes are often melted due to the high temperature during welding because of the thin pipe walls. Not only can they not be welded, but they will also damage the pipes. Many places that can use thin-walled pipes can only use thicker...

Embodiment 2

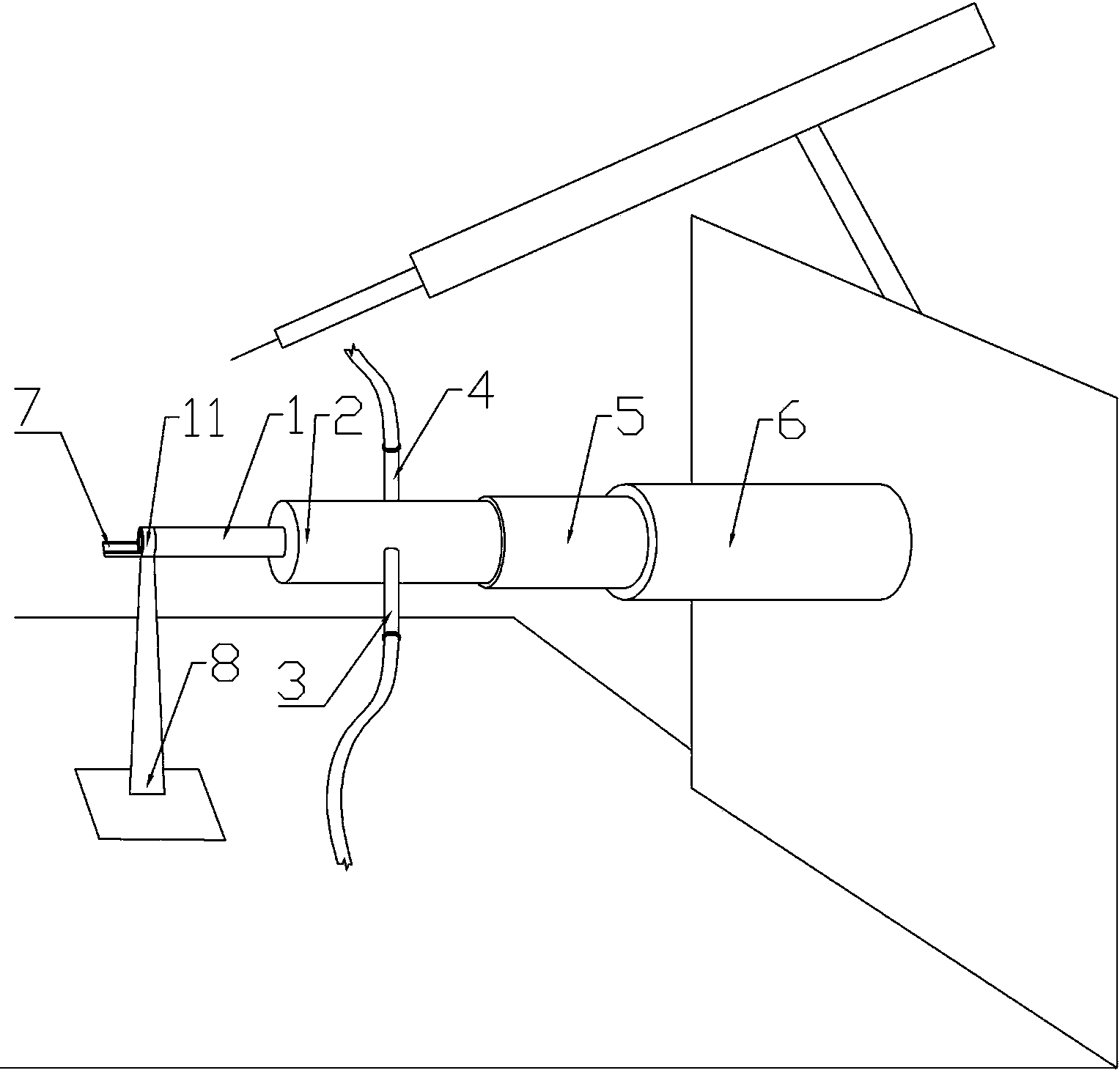

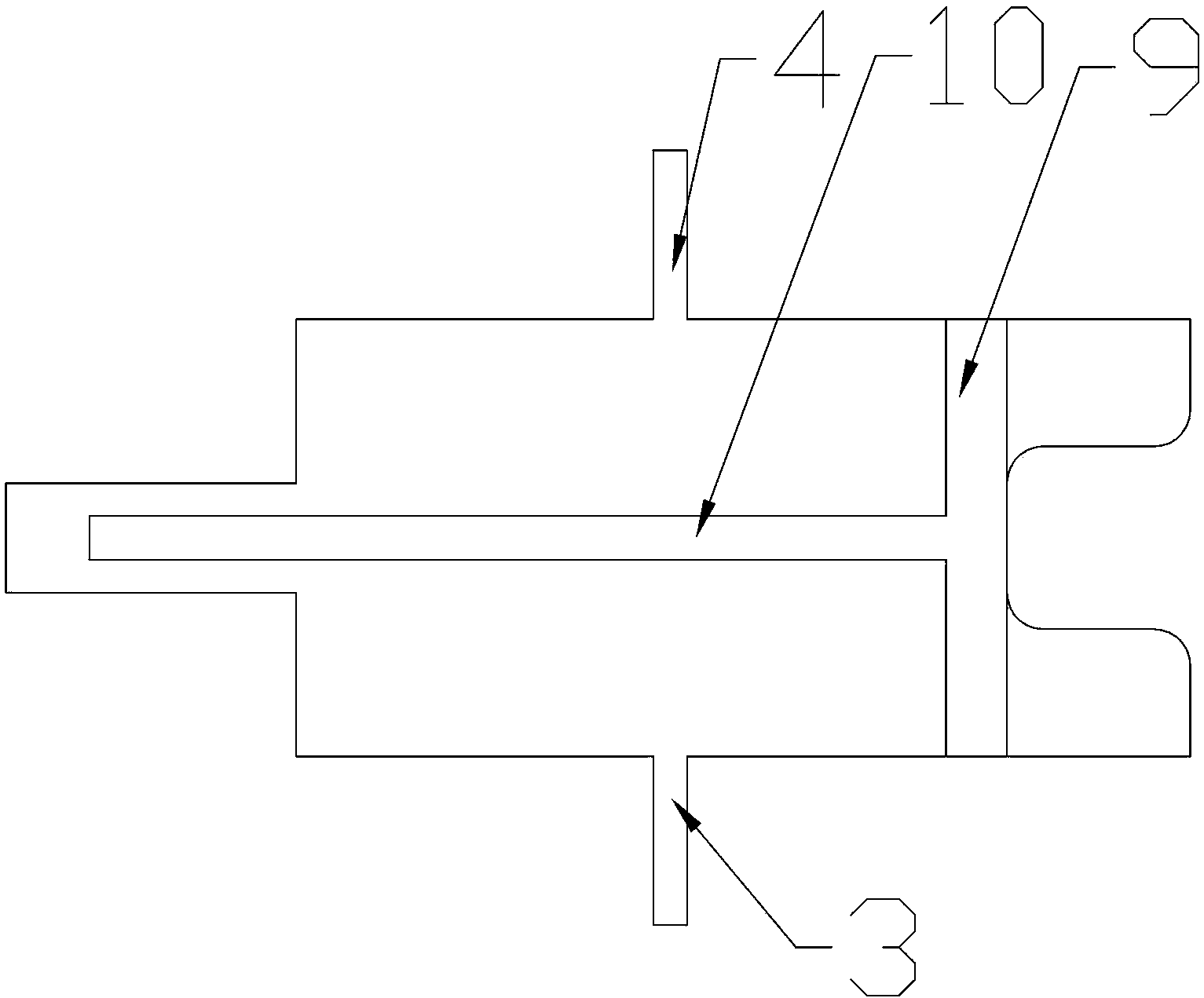

[0019] Embodiment 2, the present invention comprises cylinder liner 6, telescopic cylinder 5 is characterized in that: one end of telescopic cylinder 5 is arranged in cylinder liner 6, the other end of telescopic cylinder 5 is provided with cooling chamber 2, and the other end of cooling chamber 2 is provided with cooling chamber. Both sides of the pipe 1 and the cooling chamber 2 are provided with a water outlet 3 and a water inlet 4, and the front end of the cooling pipe 1 is provided with a balance bracket 8. During welding, the telescopic cylinder 5 and the cooling chamber 2 are extended forward to push the cooling pipe 1 into the target In the pipe, the heat in the welding area is transferred to the cooling pipe 1 through the pipe, and then transferred to the cooling water in the cooling pipe 1 by the cooling pipe 1 to achieve the purpose of controlling the temperature of the welding area. During the welding process, the water inlet and outlet 4 continuously input cooling w...

Embodiment 3

[0020] Embodiment 3, the outer diameter of the telescopic cylinder 5 according to the present invention is slightly smaller than the inner diameter of the cylinder liner 6, so that the telescopic cylinder 5 can be installed in the cylinder liner 6. refer to Figure 1 to Figure 2 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com