Transverse cutting device of extruded polystyrene foam plate production equipment

A technology of extruded polystyrene and cross-cutting device, which is applied in the direction of metal processing, etc., can solve the problems of low precision, affecting stable work, and inability to make any changes, so as to improve the quality of the section, improve the accuracy of the length, and improve the cutting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

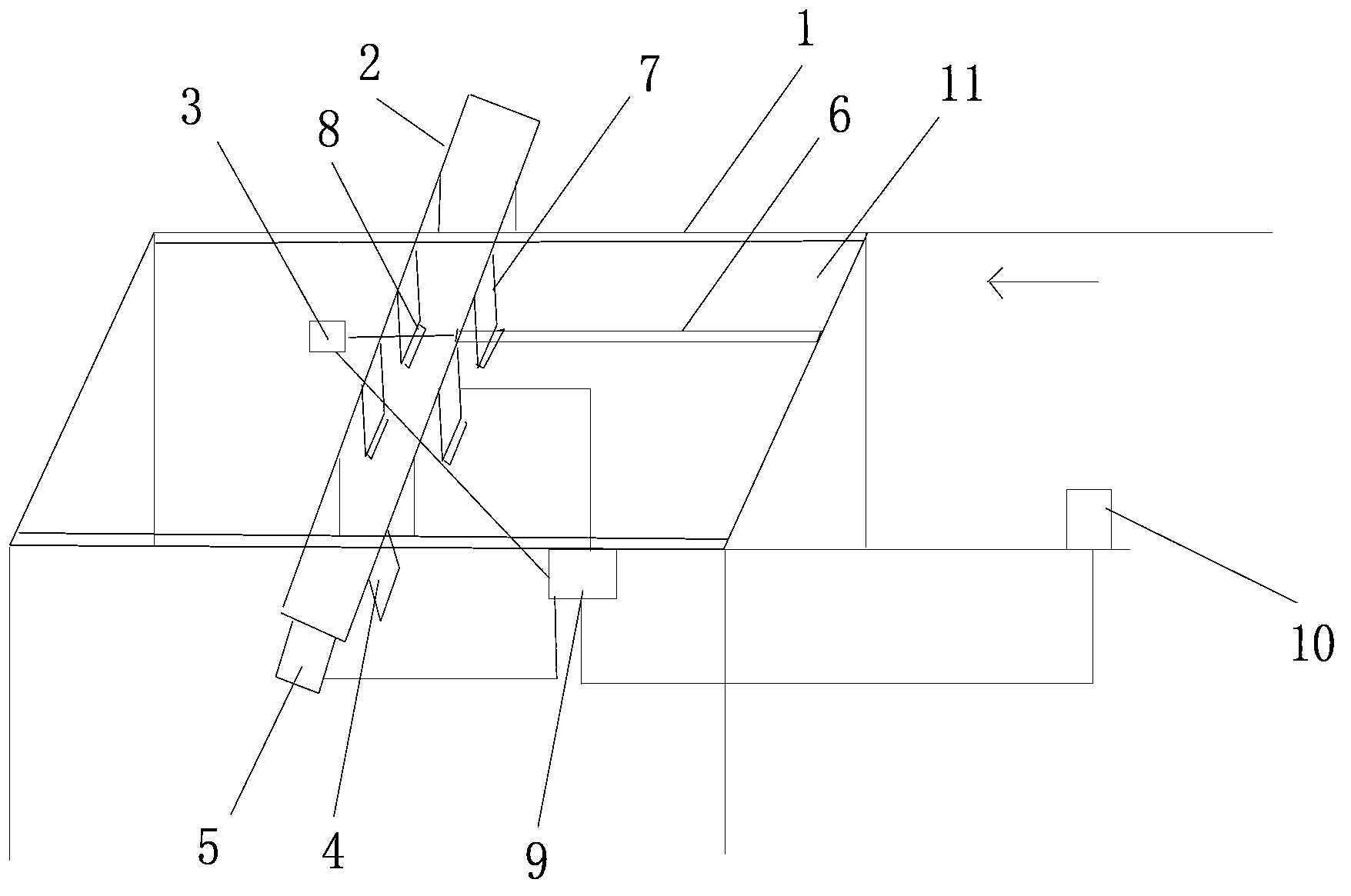

[0015] As shown in Figure 1: a cross-cutting device for producing extruded polystyrene foam board equipment, including a frame 1, a cross-cutting trolley 2, a trolley servo drive motor 3, a blade 4, a blade drive motor 5, a screw rod 6, Cylinder 7, fixed plate 8, controller 9 and encoder 10, described cross-cut trolley 2 is erected above the extruded polystyrene foam board channel 11, and cross-cut trolley 2 is installed on the vehicle frame 1 through longitudinal guide rail, cross-cut The trolley 2 is connected to the screw mandrel 6, and the screw mandrel 6 is connected to the trolley servo drive motor 3. The blade 4 is installed on the end of the cross-cutting trolley 2 through a transverse guide rail. The blade 4 is a double-edged blade on both sides, and the cylinder 7 is installed on the cross-cutting trolley 2, the cylinder 7 is four, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com