Spunlace circulating water treatment process

A treatment process and circulating water technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, textile industry wastewater treatment, etc., to achieve the effects of small footprint, easy operation and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

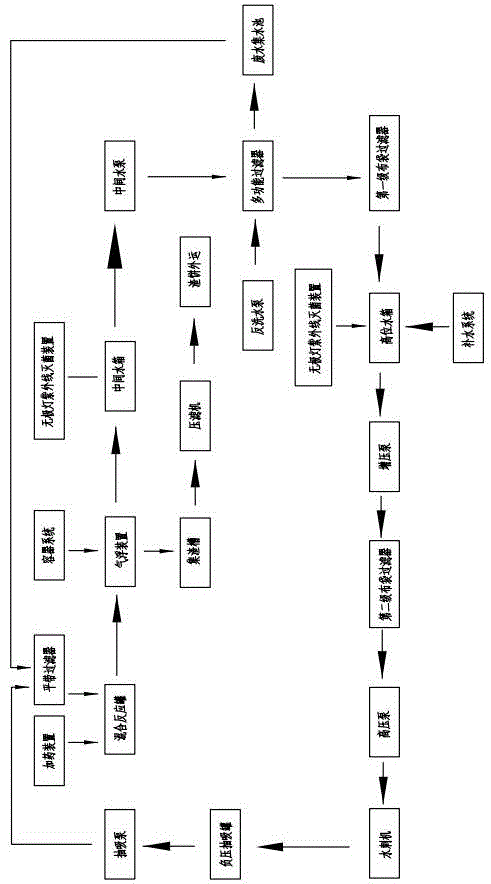

[0034] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0035] Such as figure 1 As shown, the spunlace circulating water treatment process of the present embodiment includes the following steps:

[0036] The first step: the waste water enters the mixing reaction tank through the flat belt filter, and the dosing device connected to the mixing reaction tank performs the dosing and mixing reaction;

[0037] Step 2: After the waste water is reacted in the mixing reaction tank, it enters the air flotation device, and the upper scum and bottom clean water are formed through the air flotation device, and the clean water at the bottom flows to the middle water tank;

[0038] Step 3: The intermediate water tank sends water to the multi-functional filter through the intermediate feed water pump;

[0039] Step 4: The water filtered by the multifunctional filter enters the first stage bag filter;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com