A kind of ferronickel slag pavement permeable brick and preparation method thereof

A technology of nickel-iron slag and permeable bricks, which is applied in the field of building materials, can solve the problems of consumption of nickel-iron slag, and achieve the effects of reducing energy consumption, production costs, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

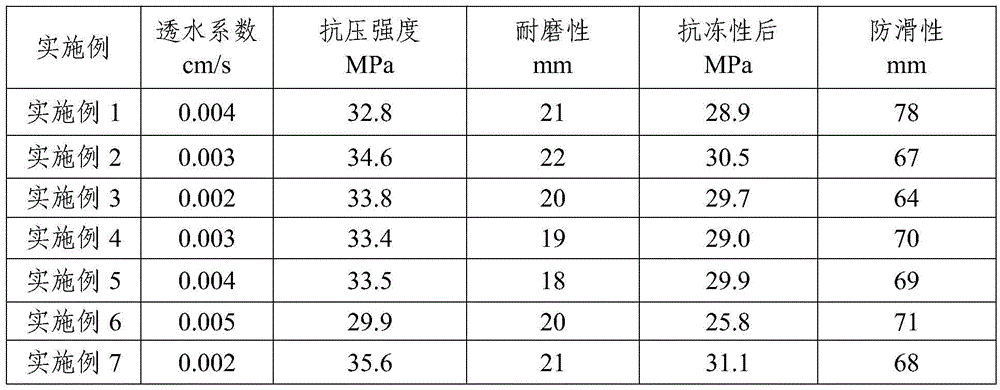

Examples

Embodiment 1

[0029] The invention discloses a pavement permeable brick made of nickel-iron slag. The raw materials (calculated on a dry basis) are 75 kg of nickel-iron slag, 1 kg of active fine powder, and 15 kg of cement.

[0030] Among them, the active micropowder is composed of 97kg ferronickel slag fine powder and 3kg active agent, and the ferronickel slag fine powder and active agent are mixed evenly according to the proportion, and then ground into 500 meshes by a mill.

[0031] The active agent is industrial gypsum.

[0032] Among them, the ferronickel slag fine powder is 500 mesh particles.

[0033] The particle size of the ferronickel slag is 15-20mm.

[0034] Its preparation method is:

[0035] Mix the raw materials according to the ratio, and use a mixer to stir evenly at a stirring speed of 30r / min; then add water to it, and control the ratio of the added water to raw materials to be 0.23, continue to stir and mix for 3 minutes, and then send the mixture to Put it into a for...

Embodiment 2

[0038] A nickel-iron slag pavement permeable brick, on the basis of embodiment 1, other preparation method steps are the same as embodiment 1, raw material (by weight on a dry basis) is nickel-iron slag 85kg, active micropowder 5kg, cement 25kg.

[0039] The active micropowder is composed of 99kg ferronickel slag micropowder and 1kg active agent, and is made by mixing the ferronickel slag micropowder and active agent uniformly according to the ratio, and then grinding it into 400 meshes with a pulverizer.

[0040] Wherein the active agent is natural gypsum.

[0041] Among them, the ferronickel slag fine powder is 400 mesh particles.

[0042] The particle size of the ferronickel slag is 10-15mm.

[0043] The curing adopts steam curing, and the steam temperature is 100°C.

Embodiment 3

[0045] A kind of ferronickel slag pavement permeable brick, on the basis of embodiment 1, other preparation method steps are the same as embodiment 1, raw material (by dry basis weight) is ferronickel slag 80kg, active micropowder 3kg, cement 20kg.

[0046] Among them, the active micropowder is composed of 95kg ferronickel slag fine powder and 5kg active agent, and the ferronickel slag fine powder and active agent are mixed evenly according to the proportion, and then ground into 300 mesh by a mill.

[0047] The active agent is industrial gypsum.

[0048] Among them, the ferronickel slag fine powder is 300 mesh particles.

[0049] The particle size of the ferronickel slag is 5-10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com