Heat exchanger for slow cooling and preheating of isothermal normalizing furnace

A technology of heat exchangers and normalizing furnaces, which is applied in the direction of preheating costs, maintenance of heating chambers, furnaces, etc., to achieve the effect of improving full recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention solves many problems encountered in the process practice of the traditional isothermal normalizing furnace, and innovatively proposes a heat exchanger for slow cooling and preheating of the isothermal normalizing furnace, so as to optimize the energy consumption of the normalizing and air-cooling quenching processes .

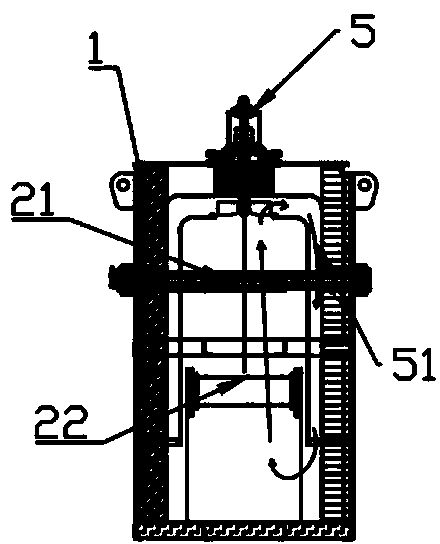

[0012] The structural features of the heat exchanger of the present invention are as figure 1 shown. In a common isothermal normalizing furnace, the furnace body 1 is provided with an upper furnace passage and a lower furnace passage. In the cold section, the middle and rear ends of the lower furnace are sequentially divided into the rapid cooling section and the isothermal section according to the material conveying direction. Conveyor mesh belts are set in the upper and lower furnace passages to carry workpieces through various temperature zones for process treatment.

[0013] As a structural improvement of this invention, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com