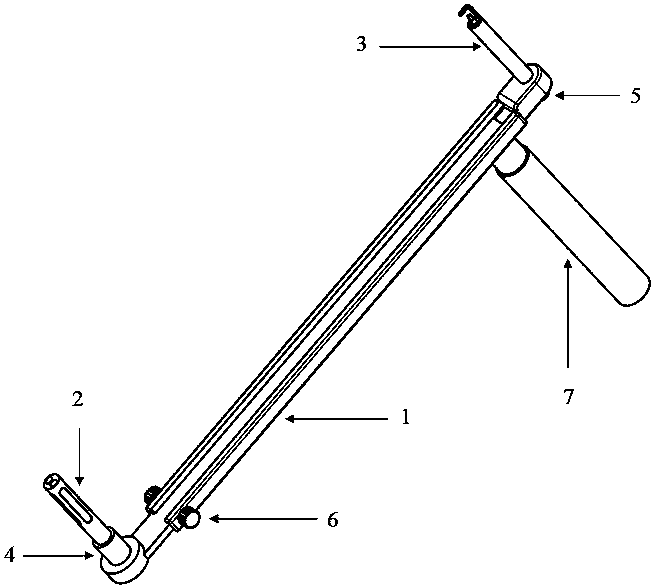

Apparatus and method for measuring acoustical absorption coefficient by using pulse sound source and sound pressure-particle velocity (PU) probe

A sound absorption coefficient and sound source technology, which is applied in the processing of detection response signals, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of limited effective frequency response range of speakers, unguaranteed, large error of sound absorption coefficient, etc. Achieve the effect of convenient measurement and adjustment, and expand the measurement frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

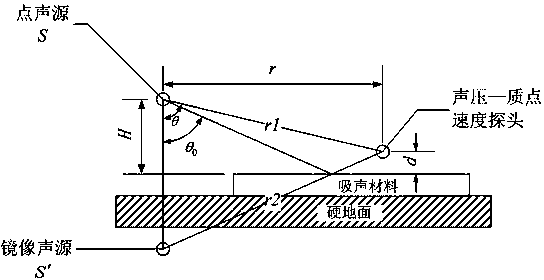

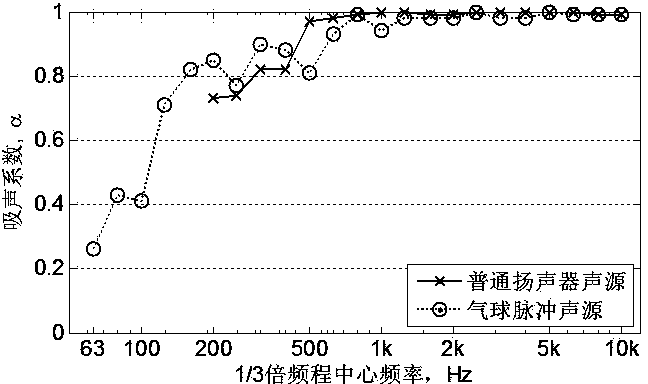

[0055] The acoustic material measured in the case is melamine foam, and the length, width, and thickness are 1500 mm×670 mm×100 mm, respectively. LMS Q-sources mid-frequency volume sound source is used as the speaker sound source, and the effective frequency range of the sound source is 200 Hz~8 kHz. A B&K 3560C was used as a signal generator and data acquisition system, emitting pink noise with a frequency bandwidth of 6.4 kHz. A balloon was used as the pulse sound source, and Matlab was used for data post-processing.

[0056] Such as figure 2 As shown, the material to be tested is laid flat on the ground, the sound pressure-particle velocity probe is located at the geometric center of the material, and the height of the probe from the surface of the material is d =1 cm. Place the sound source directly above the sound pressure-particle velocity probe, that is , the height of the sound source from the surface of the material H =100 cm. Excite the sound source of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com