Method for testing surface free energy of graphene by using inverse gas chromatographic method

An inverse gas chromatography, graphene surface technology, applied in the field of nanomaterial characterization, can solve the problems of poor repeatability and complicated operation, and achieve the effect of high repeatability, simple operation and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

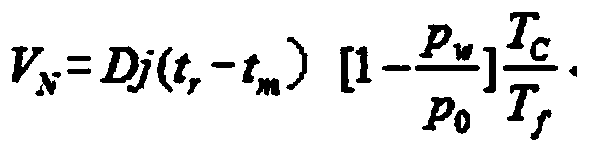

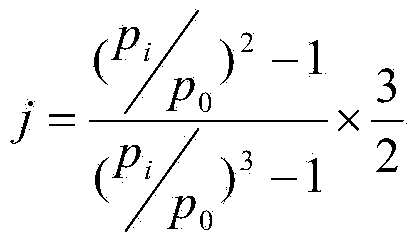

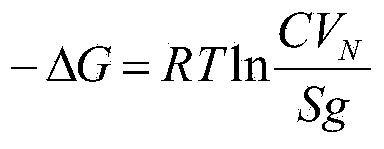

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in combination with specific embodiments.

[0037] Concrete steps of the present invention are as follows:

[0038] 1) Dry the graphene sample to be tested in a vacuum oven at 200° C. for 5 hours.

[0039] 2) Put 0.35 g of the sample obtained in step 1) into a clean stainless steel packed column with an inner diameter of 3 mm, an outer diameter of 4 mm, and a length of 30 cm; before filling, the packed column should be purified, washed with acetone, dried at high temperature, and then filled into graphene.

[0040] 3) Before the test, the packed column should be activated to eliminate the effect of surface volatile substances on the graphene adsorption performance. The specific operation is: install the packed column obtained in step 2) on the chromatograph, and under the condition that the oven temperature is 180°C and the helium gas flow rate is about 16mL / min, only helium gas is passed through, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface energy | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com