Automatic measuring system for insulating material surface charge two-dimensional distribution

A surface charge, two-dimensional distribution technology, applied in the measurement device, measuring electrical variables, testing dielectric strength and other directions, can solve problems such as low signal-to-noise ratio, inaccurate scanning results, and poor anti-interference performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

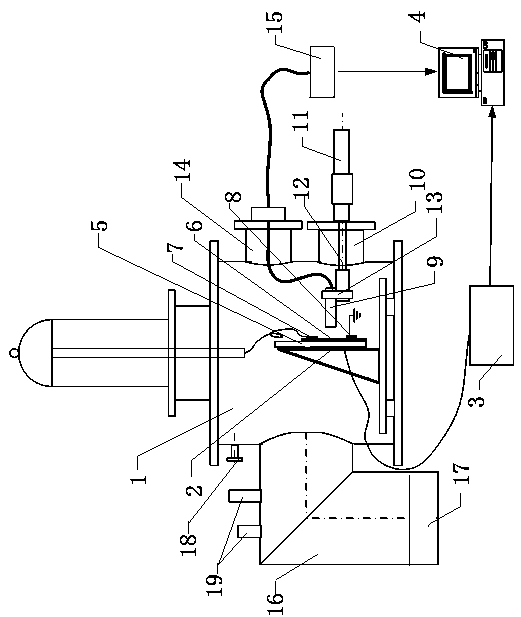

[0019] Such as figure 1 As shown, the automatic measurement system for the two-dimensional distribution of the surface charge of insulating materials according to the present invention includes a closed cavity 1, the closed cavity 1 can be a stainless steel closed cavity 1, and the gas atmosphere in the stainless steel closed cavity 1 can be vacuum, atmospheric or other gases.

[0020] The stainless steel airtight cavity 1 is provided with a two-dimensional electronically controlled displacement platform 2, and the two-dimensional electronically controlled displacement platform 2 is composed of two electronically controlled displacement platforms with a horizontal axis X and a vertical axis Y. Among them, the horizontal axis X electronically controlled translation stage adopts Zhuoli Hanguang TSC30, the moving range is 30mm, and the minimum step distance is 0.625μm; the vertical axis Y electronically controlled translation stage adopts Zhuoli Hanguang TSA100, the moving range ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com