A fast-response thermosensitive chip and its manufacturing method

A fast response and manufacturing method technology, applied in the direction of resistors with negative temperature coefficients, etc., can solve the problem that the reaction speed cannot meet the requirements of high sensitivity of temperature detection, can not respond to temperature well, and the porcelain body is prone to cracks, etc. Achieve the effect of meeting high sensitivity requirements, improving mechanical strength, and small thermal time constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

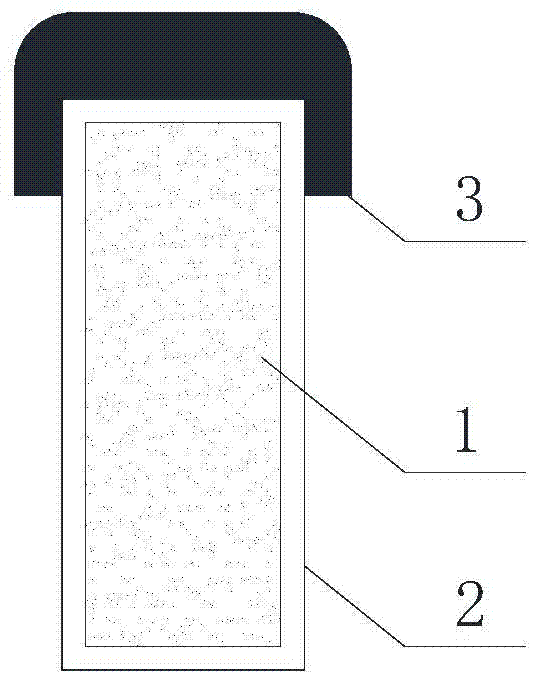

[0036] Such as image 3 As shown, a kind of rapid response thermosensitive chip 10 of the present invention comprises a ceramic substrate 1, the two surfaces of the ceramic substrate 1 are printed with surface electrodes 2, and one end of the ceramic substrate 1 passes through The heat-sensitive material layer 3 is sealed, and the ceramic substrate is an alumina substrate, and the heat-sensitive material is made of at least two or two kinds of oxides such as manganese oxide, cobalt oxide, iron oxide, nickel oxide, etc. The above oxides are prepared according to a certain ratio of NTC semiconductor materials.

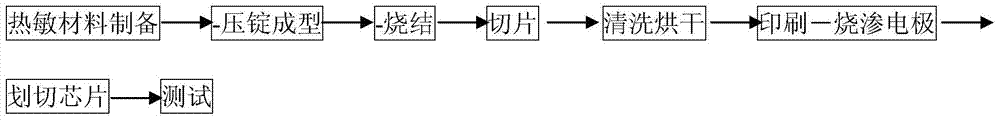

[0037] The present invention also discloses a method for manufacturing the above-mentioned rapid response thermal chip, the specific steps of which are:

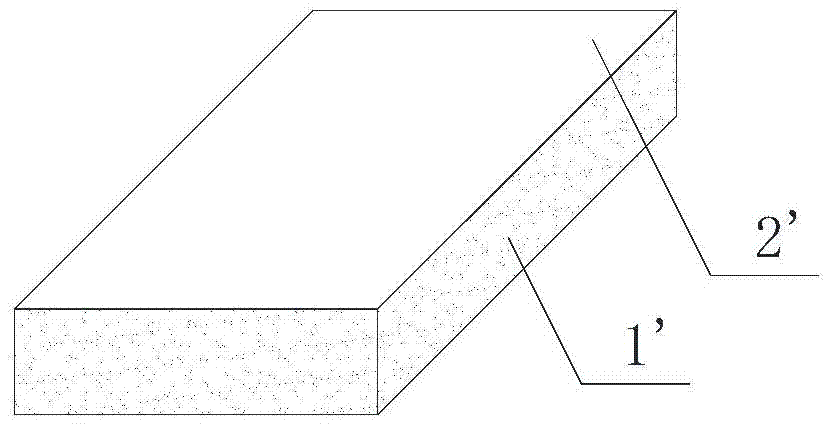

[0038] (1) Choose ceramic substrate 1: such as Figure 4a As shown, the ceramic substrate 1 made of alumina with a thickness of 0.1-0.2 mm is selected, which has high hardness and strong wear resistance, can be used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com