Preparation method for blending type contrast agent with T1 and T2 contrast functions

A technology of contrast agent and function, which is applied in the field of preparation of blended contrast agent, which can solve the problems of brightening the enhanced picture and not being able to achieve image signals at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Dissolve 0.718g of F127 in 25mL of secondary deionized water, and sonicate at 50°C for 30min to fully dissolve it.

[0027] 2. Slowly add 0.189g of terephthalic acid, 0.160g of gadolinium trichloride and 0.041g of ferric chloride hexahydrate into the above solution, and continue to sonicate until a uniform and transparent solution is obtained.

[0028] 3. Put the transparent solution obtained in 2 into the hydrothermal reaction kettle, and react at 150°C for 24h.

[0029] 4. After the reaction, centrifuge the reaction solution to remove the secondary deionized water reaction solution.

[0030] 5. The crude product was then washed twice with N,N-dimethylformamide to remove unreacted raw materials.

[0031] 6. Put the solid obtained in 5 into ethanol at 80°C for 1d to remove F127.

[0032] 7. Finally, the product from which F127 was removed in 6 was washed 3 times with ethanol. The target product Gd was obtained after vacuum drying at 60 °C for 24 h 80 Fe 20 . Ex...

Embodiment 2

[0033] 1. Dissolve 0.718g of F127 in 25mL of secondary deionized water, and sonicate at 50°C for 30min to fully dissolve it.

[0034] 2. Slowly add 0.189g of terephthalic acid, 0.04g of gadolinium trichloride and 0.164g of ferric chloride hexahydrate into the above solution, and continue to sonicate until a uniform and transparent solution is obtained.

[0035] 3. Put the transparent solution obtained in 2 into the hydrothermal reaction kettle, and react at 150°C for 24h.

[0036] 4. After the reaction, centrifuge the reaction solution to remove the secondary deionized water reaction solution.

[0037] 5. The crude product was then washed twice with N,N-dimethylformamide to remove unreacted raw materials.

[0038] 6. Put the solid obtained in 5 into ethanol at 80°C for 1d to remove F127.

[0039] 7. Finally, the product from which F127 was removed in 6 was washed 3 times with ethanol. The target product Gd was obtained after vacuum drying at 60 °C for 24 h 20 Fe80 .

Embodiment 3-6

[0041] The difference between embodiment 3-6 and embodiment 1~2 is shown in the table below:

[0042]

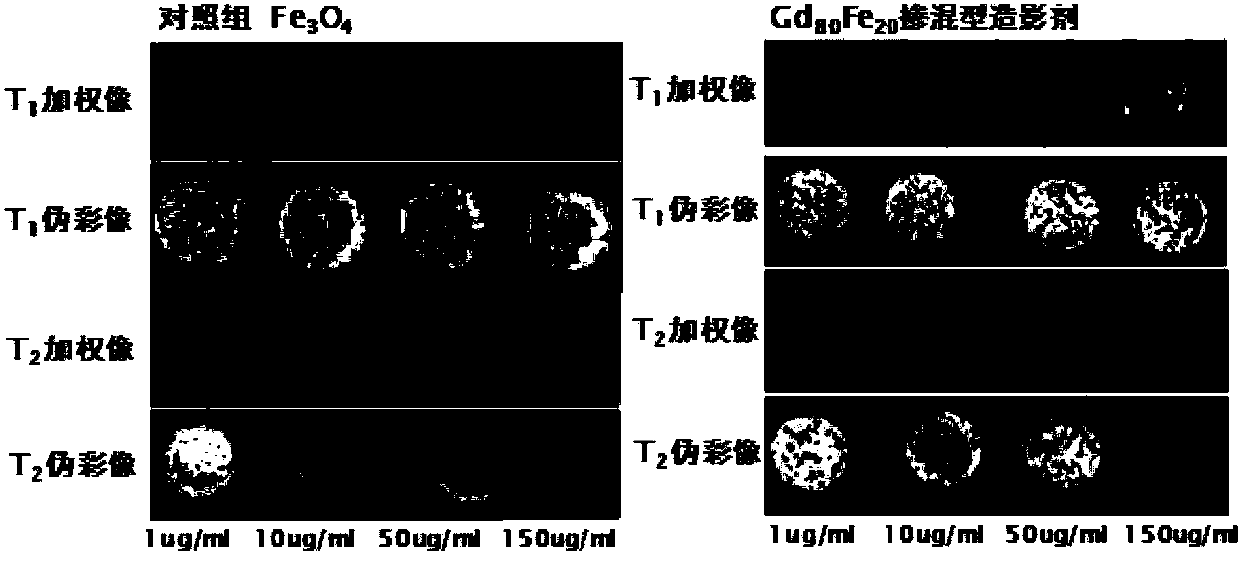

[0043] T 1 , T 2 Contrast agent structure and MR properties characterization

[0044] The JEM-2000EX transmission electron microscope produced by Japan JEOL Electronics Co., Ltd. and the MinMR-60 and NMI20 magnetic resonance instrument produced by Shanghai Numai Electronic Technology Co., Ltd. were used to analyze the blended contrast agent Gd prepared by the present invention. 80 Fe 20 and Gd 20 Fe 80 The particle size morphology and contrast agent imaging were characterized, and the results are as follows Figure 1~4 shown.

[0045] Figure 1~4 The blended contrast agent Gd prepared in Examples 1-2 of the present invention is shown 80 Fe 20 and Gd 20 Fe 80 The materials are evenly dispersed, the former resembles a mulberry structure and the latter resembles a needle-like structure, with sizes at 70nm (short end), 150nm (long end) and 140nm (short end), 890nm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com