Driving and rake lifting device of center driving thickener

A transmission device and concentrator technology, applied in chemical instruments and methods, separation methods, precipitation separation, etc., to achieve the effect of improving transmission efficiency, improving stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

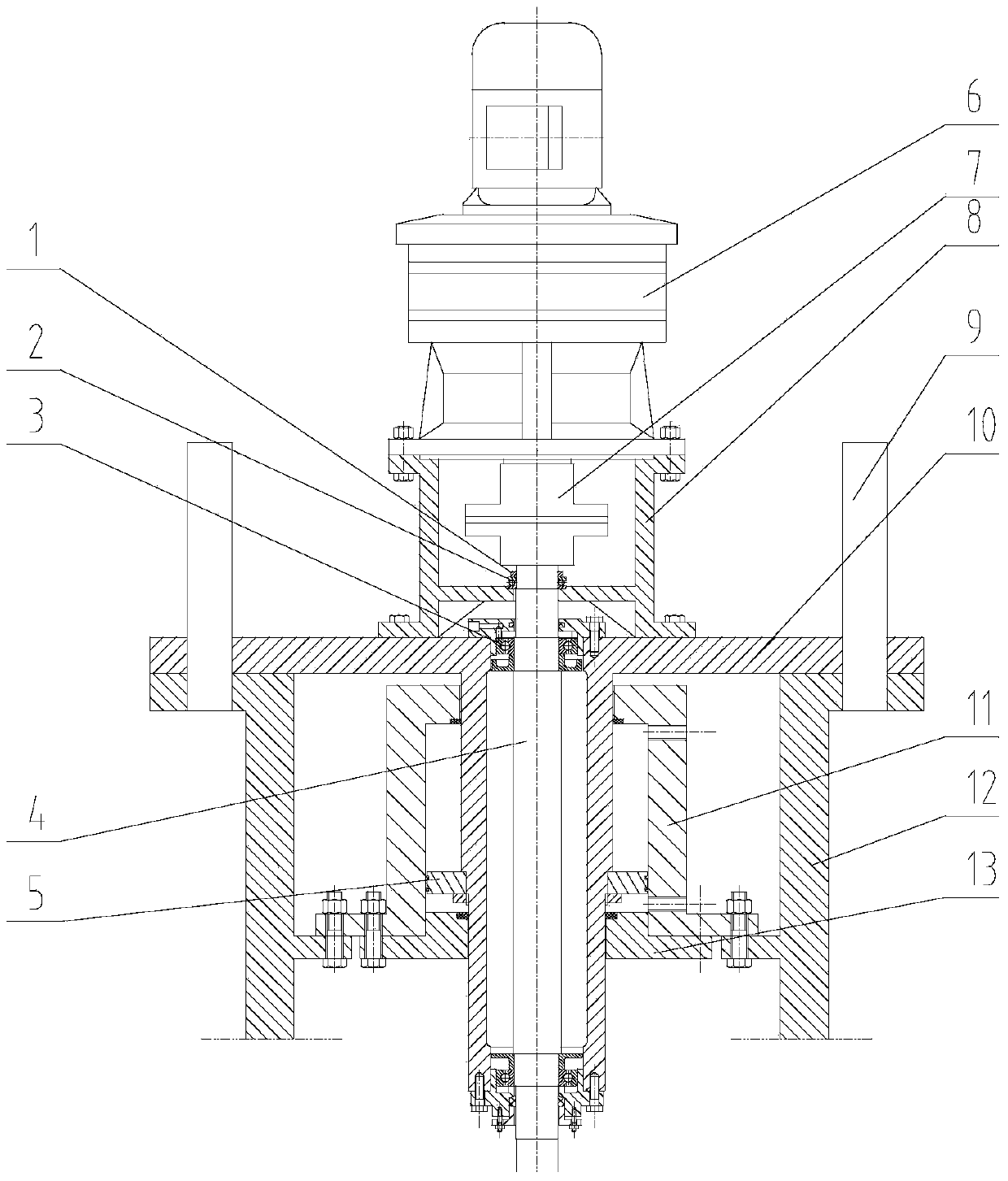

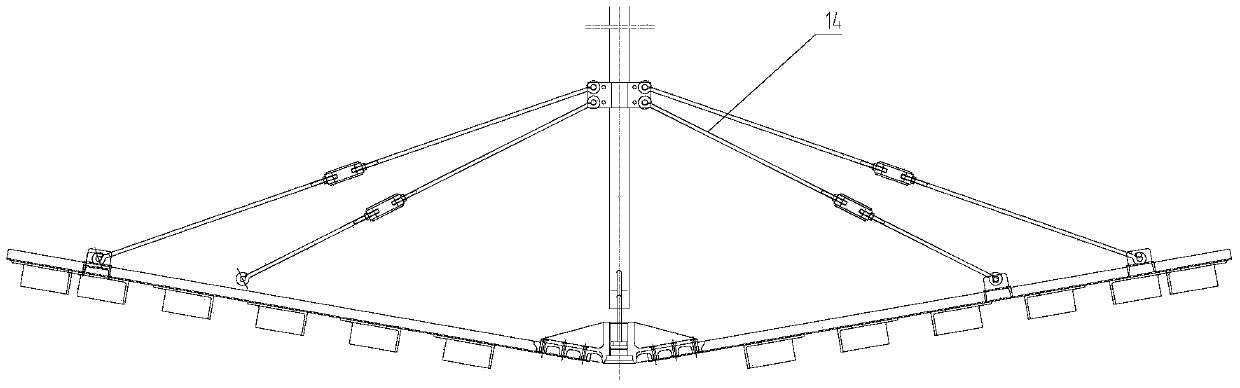

[0023] The rake 14 is installed on the bottom of the transmission shaft 4, and the transmission shaft 4 is supported by two pairs of rolling bearings 3 up and down to bear radial force, and the rolling bearings 3 are installed in the bearing body 10. A thrust ball bearing 2 and a retaining ring 1 are installed on the upper part of the transmission shaft 4, and the thrust ball bearing 2 is installed on the top of the bearing body 10, so that the axial force of the entire transmission shaft 4 is borne by the bearing body 10 through the thrust ball bearing 2 . The transmission shaft 4 is connected to the motor direct-coupled reducer 6 on its upper part through a coupling 7 , and the motor direct-coupled reducer 6 is fixed on the top of the bearing body 10 through a bracket 8 . And piston 5 is also installed on the bearing body 10, and its outside is covered with cylinder body 11, and bearing body 10, piston 5, cylinder body 11 have formed a double-acting hydraulic cylinder. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com