Rail-spraying magnetic drill floor

A technology of magnetic drilling and rail spraying, which is applied to workbenches, dust removal, chemical instruments and methods, etc., can solve problems such as dust pollution, poor processing environment, and potential safety hazards, improve safety and sanitation, and solve safety problems , the effect of reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

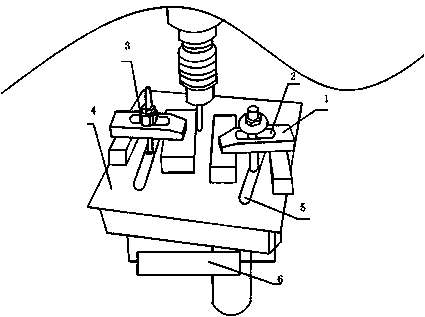

[0020] see figure 1 , The spray rail magnetic drilling platform includes a pressing block 1, a fixing bolt 3, a supporting platform 4, a U-shaped chute 5 and an electromagnet 6. The above-mentioned supporting platform 4 is provided with a U-shaped chute 5 on the horizontal plane, and the pressing block 1 is perpendicular to the horizontal plane. The axis of the axis passes through the U-shaped chute 5, and the above-mentioned fixing bolt 3 passes through the pressing block 1 and extends into the U-shaped chute 5. The pressing block 1 can be moved and adjusted along the U-shaped chute 5 according to the position requirements of the drilling of industrial components. At the processing position, the above-mentioned electromagnet 6 is set under the support platform 4. The electromagnet 6 is set to absorb the waste chips left by the drill bit processing, so that the waste chips will not splash around and affect the worker's operation. It is set under the support platform. It is to...

Embodiment 2

[0023] Similar to Embodiment 1, the spray rail magnetic drill floor includes a pressure block 1, a fixing bolt 3, a support platform 4, a U-shaped chute 5 and an electromagnet 6. The difference is that the above-mentioned support platform 4 is rectangular, and a U-shaped The chute 5, the U-shaped chute 5 is parallel to one side of the support table 4. The axis of the pressing block 1 perpendicular to the horizontal plane passes through the U-shaped chute 5, and the above-mentioned fixing bolt 3 passes through the U-shaped groove 2 of the pressing block 1 and extends into the U-shaped chute 5. The pressing block 1 can be used according to industrial parts The location of the drill hole needs to move along the U-shaped chute 5 to adjust the processing position of the parts. The above-mentioned electromagnet 6 is arranged under the support table 4. The electromagnet 6 is arranged to absorb the waste chips left by the drilling process, so Waste chips will not splash around and aff...

Embodiment 3

[0025] Similar to Embodiment 1 and Embodiment 2, the difference is that the above-mentioned electromagnet 6 is a suction cup type electromagnet, a suspension type electromagnet or a frame type electromagnet, and the magnetic size of the above-mentioned electromagnet 6 is ≧80N / cm 2 . The sucker type electromagnet, suspension type electromagnet or frame type electromagnet is convenient to be placed under the support table 4 .

[0026] The adsorption capacity of the electromagnet 6 should not be too large, so as to prevent affecting the normal operation of other workpieces, it can absorb waste chips and prevent them from splashing, and a certain amount of waste chips can be collected for centralized treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com