Liquid phase laser three-dimensional printing system and method based on nanoparticles

A nanoparticle and laser three-dimensional technology, applied in the field of 3D printing, can solve the problems of increased powder adhesion, rough surface of the processing structure, insufficient internal bonding, etc., to achieve high printing resolution and printing accuracy, reduce laser power, The effect of high-efficiency printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

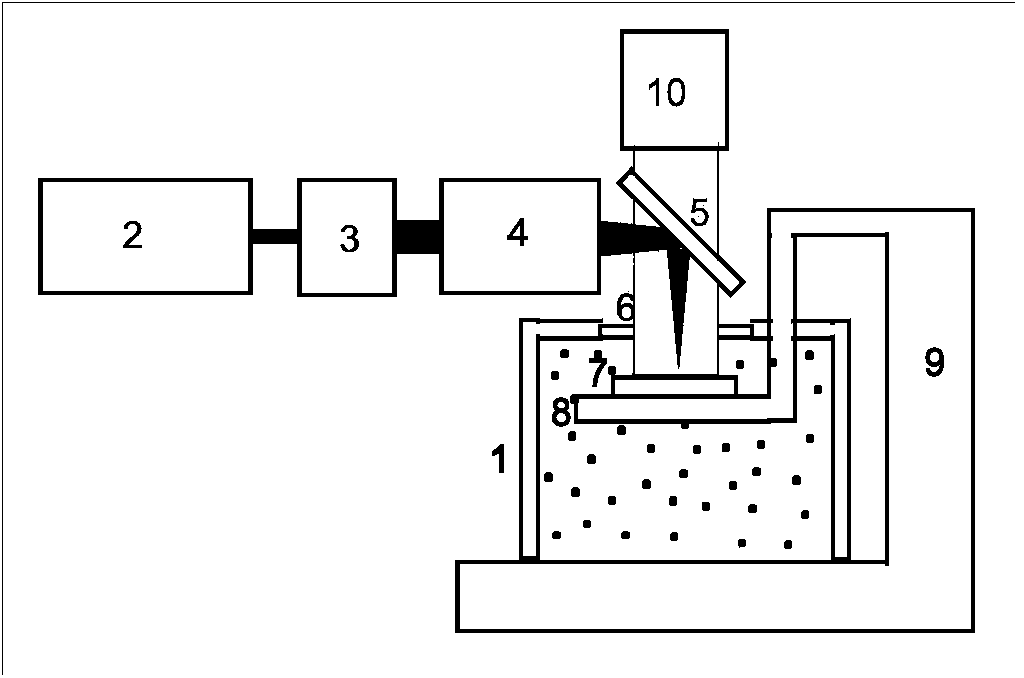

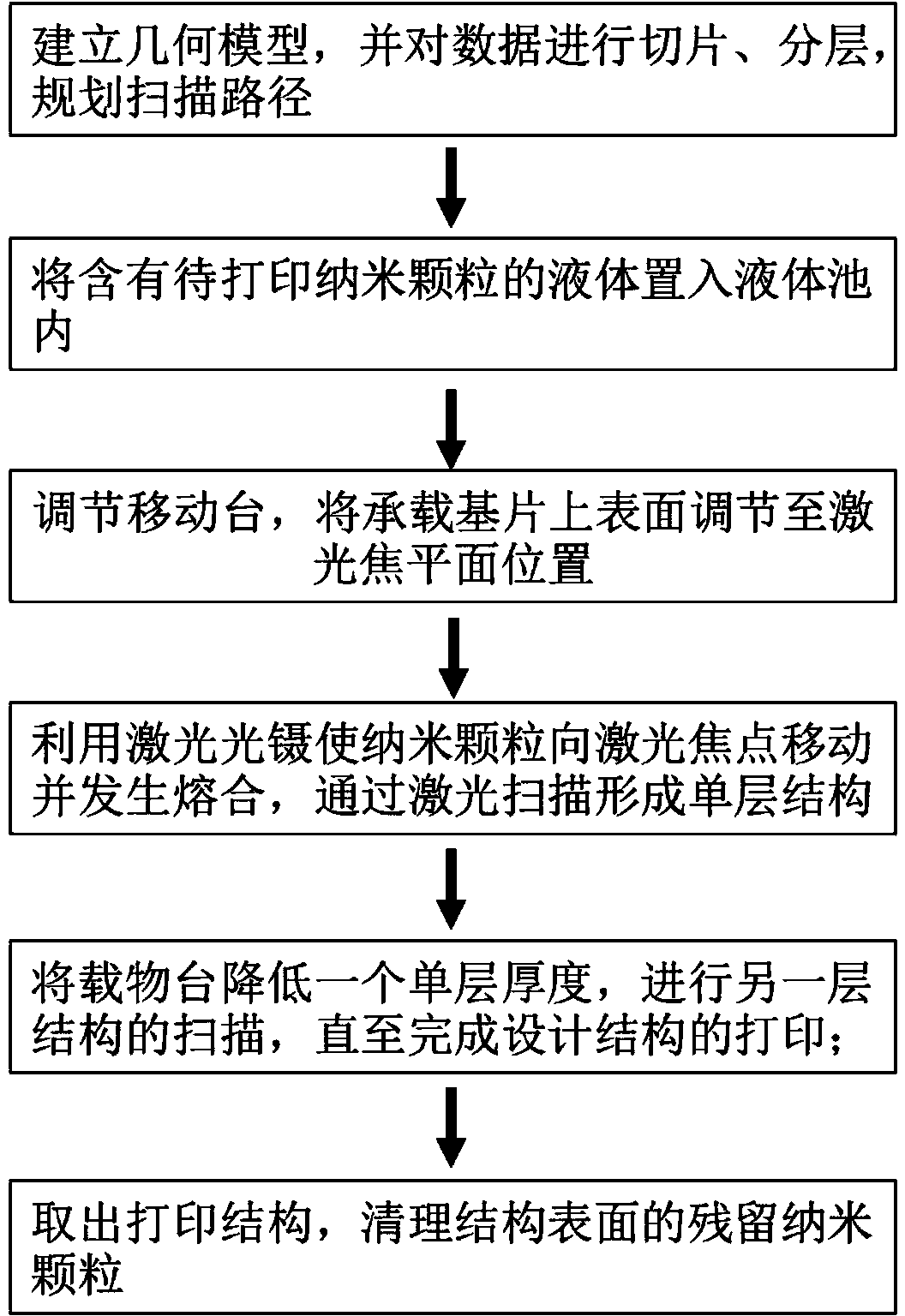

[0047] Combine the following figure 1 and figure 2 , the present invention will be described in detail by taking the nanoparticle-based liquid-phase laser three-dimensional printing system and method of gold structure as an example. The selected gold nanoparticles have a particle size of 5 nm.

[0048]First, use computer graphics software to establish a geometric model, slice and layer the data, and plan the scanning path.

[0049] Put the liquid containing the gold nanoparticles to be printed into the liquid pool 1 .

[0050] Adjust the moving stage 9 to adjust the upper surface of the carrier substrate 7 placed on the stage 8 to a position close to the upper surface of the liquid in the liquid pool, and to be on the focused laser focal plane.

[0051] A 532nm green laser is selected as the laser light source 2, and the laser power is 20-100mW. Using laser optical tweezers, the gold nanoparticles in the solution move to the laser focus and fuse under the action of light ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com