Honeycomb-type composite material laminboard and hot press molding method thereof

A composite material and hot pressing forming technology, which is applied in the field of composite material forming, can solve the problems of low internal shear and exploitation performance, poor buckling deformation resistance, uncontrollable molding quality, etc., and achieve high internal shear and exploitation performance, Stable mechanical properties and good buckling deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

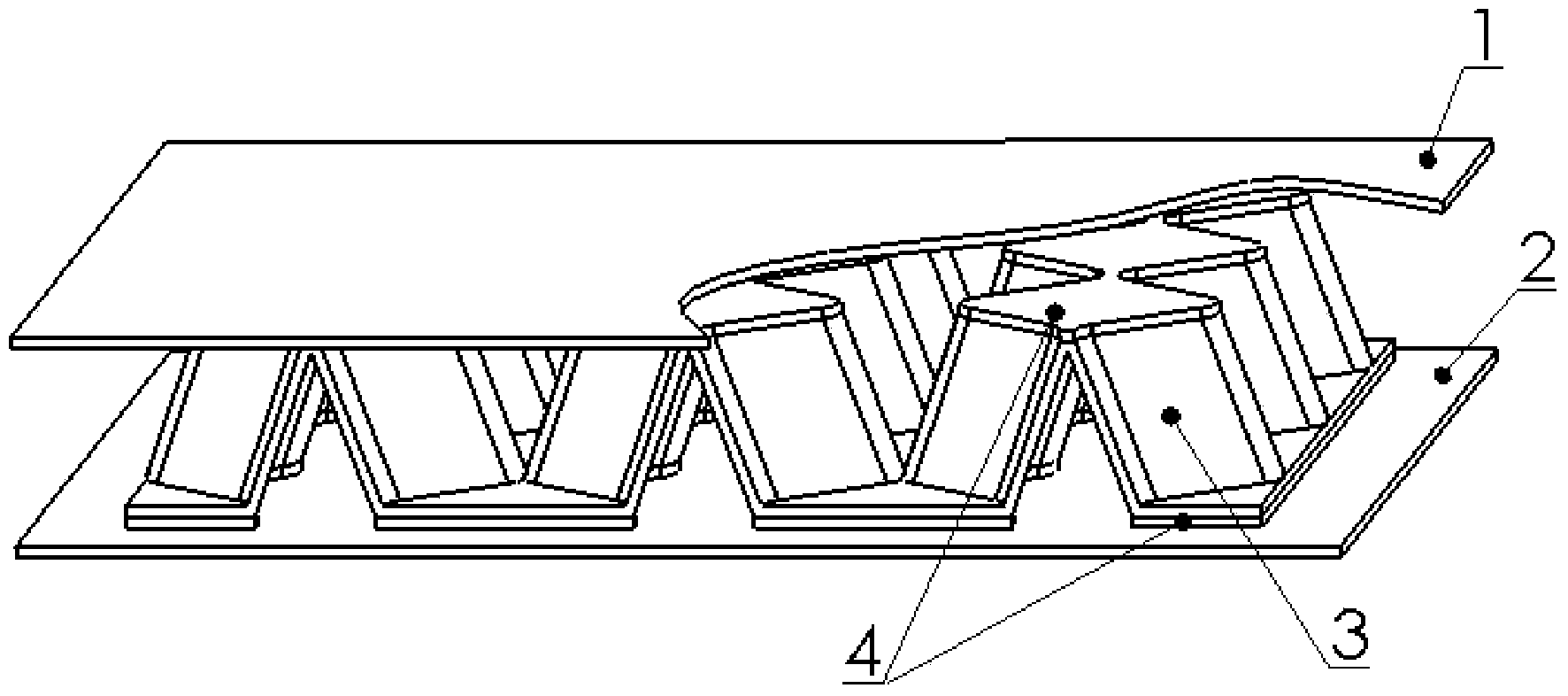

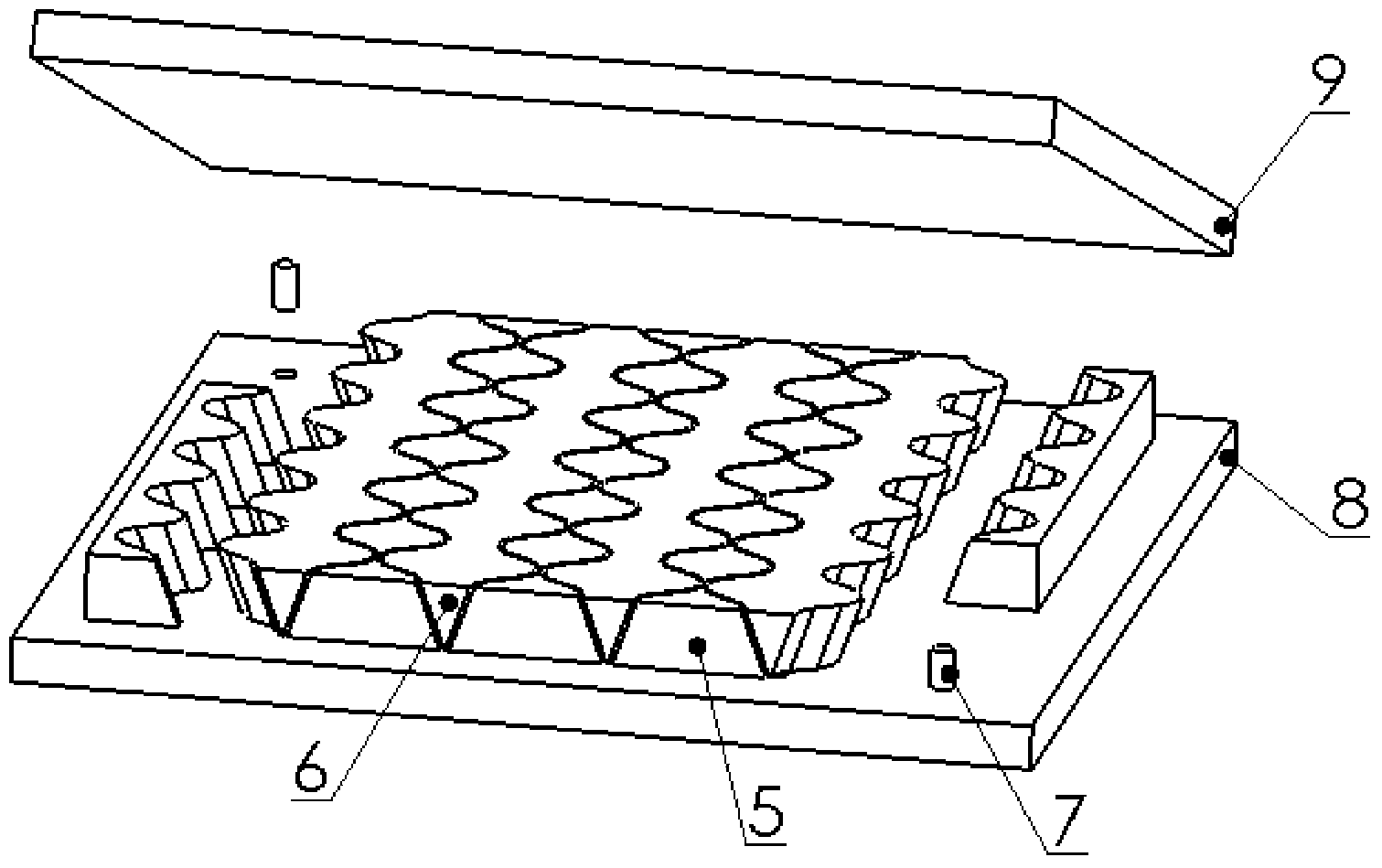

[0022] Specific implementation mode one: as Figure 1~2 As shown, the honeycomb-like composite sandwich panel in this embodiment includes an upper panel 1, a lower panel 2 and a core layer 3, the core layer 3 is fixedly arranged between the upper panel 1 and the lower panel 2, and the core layer 3 is composed of multiple Composed of herringbone units, multiple herringbone units are arranged in a matrix between the upper panel 1 and the lower panel 2, adjacent herringbone units are interwoven horizontally and vertically and fixed as a whole, and the space formed between two adjacent rows of herringbone units Tapered from top to bottom, the space formed by the lower part of each row of herringbone units is gradually expanded from top to bottom, and the upper and lower edges of each row of herringbone units are wavy.

specific Embodiment approach 2

[0023] Specific implementation mode two: as figure 1 As shown, in this embodiment, the space formed between two adjacent rows of herringbone units is consistent with the space formed by the lower part of each row of herringbone units. Such setting can ensure that the prepreg maintains consistent deformation during the folding process. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: as figure 1 As shown, the core layer 3 in this embodiment is bonded between the upper panel 1 and the lower panel 2 , and the core layer 3 is bonded to the upper panel 1 and the lower panel 2 through the adhesive layer 4 . With such a design, compared with riveting, a large number of rivets are saved, and the mechanical properties are improved at the same time. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com