Choke plug structure for primary mold of glass mold

A technology of glass moulds, bulkheads, applied in glass molding, glass blowing, glass manufacturing equipment, etc., which can solve problems such as spring fatigue, complex structure, and affecting the smooth flow of gas, so as to achieve convenient production and assembly and smooth guarantee Flowing, simple structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable the examiners of the patent office, especially the public, to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail the following in the form of examples, but none of the descriptions to the examples is an explanation of the solutions of the present invention. Any equivalent transformation made according to the concept of the present invention which is merely formal but not substantive shall be regarded as the scope of the technical solution of the present invention.

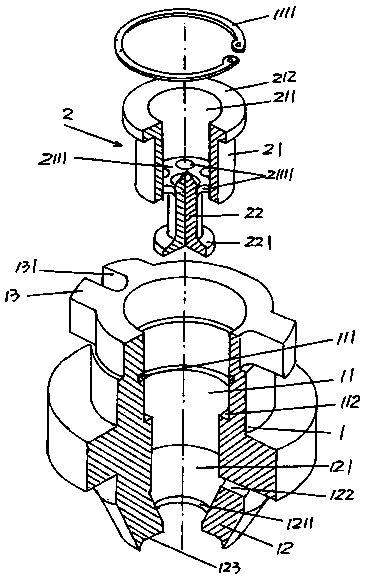

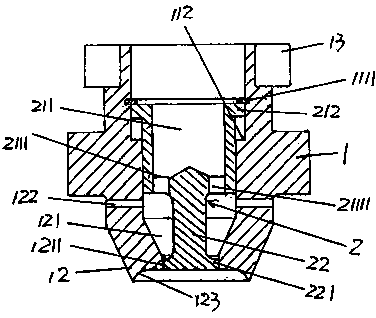

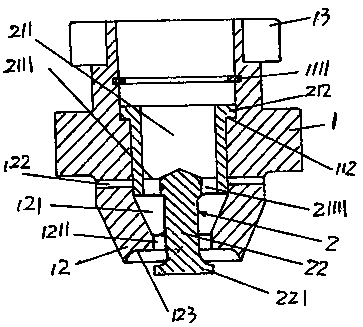

[0019] See figure 1 , a valve body 1 and a valve core 2 arranged in the valve body cavity 11 of the valve body 1 in a floating state are provided, and there are ( That is to say, it is processed with) a spool limiter groove 111 that is recessed in the surface of the cavity wall of the valve body cavity 11 and is circular or through, and a spool limiter 1111 is embedded in the spool limiter groove 111 , In th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap