Controllable mechanical seal based on closing force change

A mechanical seal, closing force technology, applied in the direction of engine seal, mechanical equipment, engine components, etc., can solve the problems of slow dynamic control response and poor reliability of mechanical seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

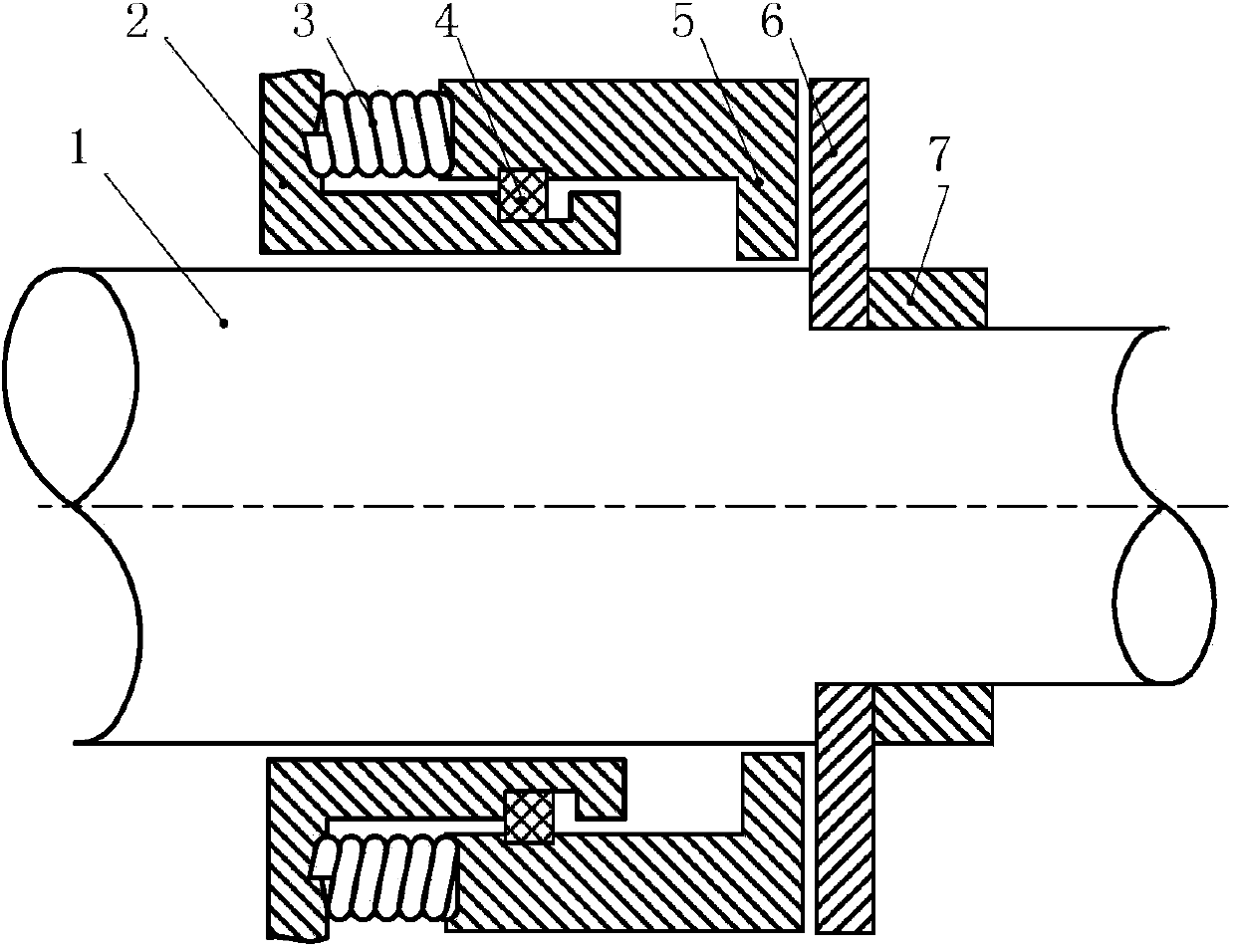

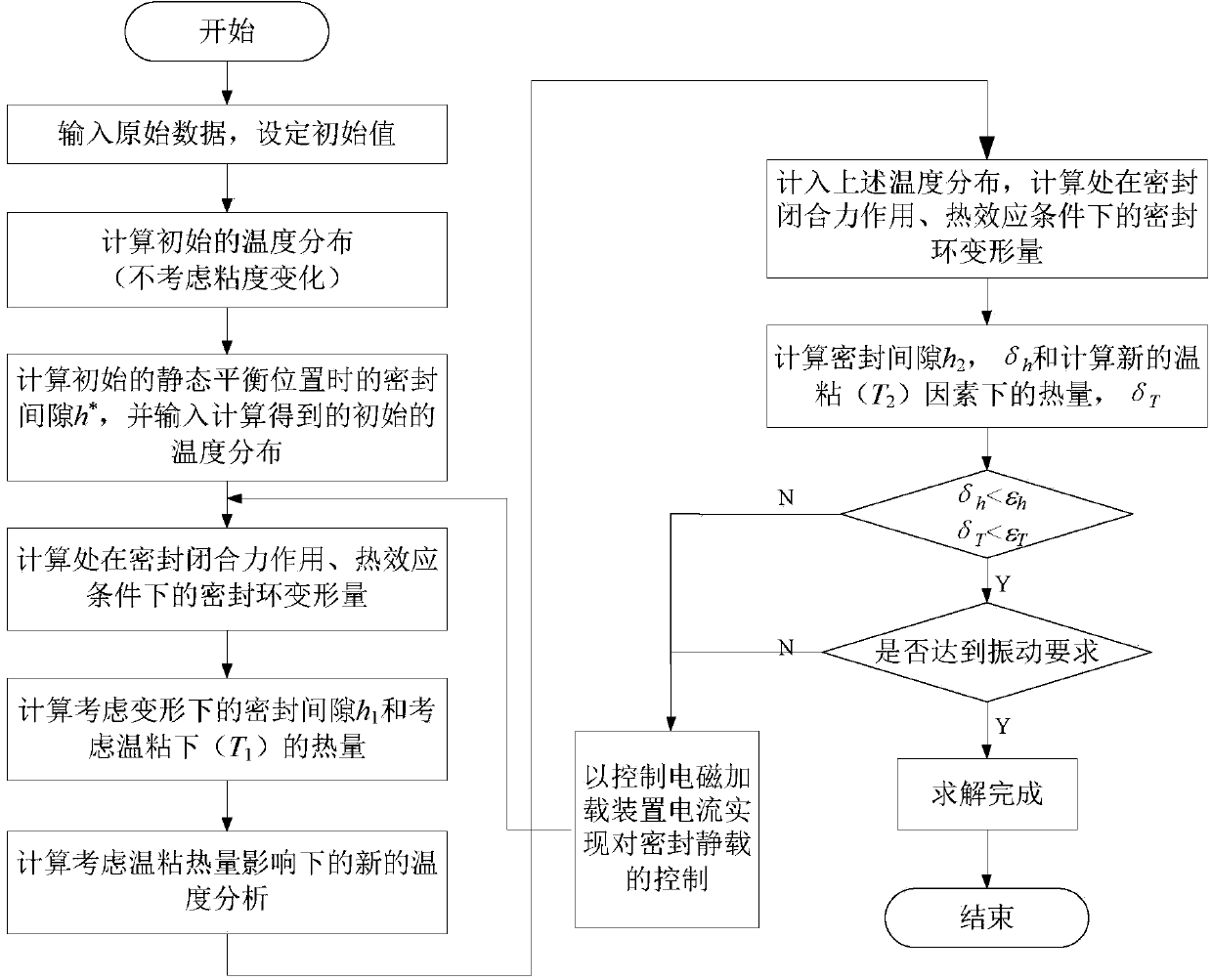

[0036] In order to expand the working range of the mechanical seal, improve the service life and working reliability of the seal, and solve the main contradiction of ensuring low friction and low wear of the sealing pair while ensuring low leakage, the present invention proposes a controllable seal based on changing the closing force. Type mechanical seal, (controllable mechanical seal is classified according to the controlled quantity, which can be divided into the following two types: one is to control the working condition of the sealing by adjusting the opening force, and the other is to control the working condition of the sealing by adjusting the closing force According to the control method of the mechanical seal, it can be divided into two types: open loop and closed loop; the earliest controllable mechanical seals are all adjusted to the closing force through the open loop control system.) Including the static ring seat 2, the installation The electromagnetic loading d...

Embodiment 2

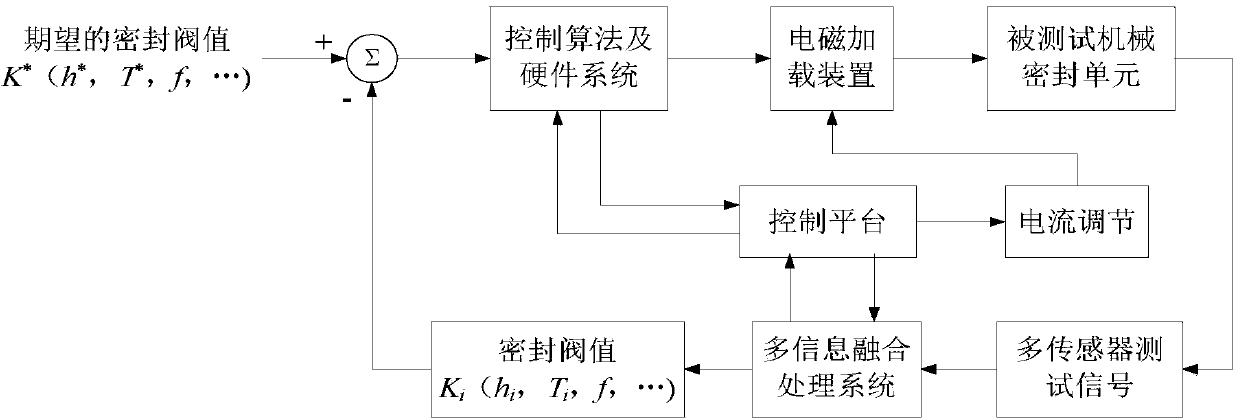

[0043] The technical scheme of sealing control proposed in this proposal is to adjust the closing force of the sealing by changing the dynamic compensation force of the sealing to realize the closed-loop control of the sealing. attached figure 1 A structural schematic diagram of a mechanical seal is given. The dynamic compensation force is supplied and realized by the axial electromagnetic loading device 13 loaded on the end cover part, such as Figure 4 shown.

[0044] After using the electromagnetic loading device 13, the closing force of the mechanical seal is composed of three parts, namely the spring compensation unit F s , The hydrostatic pressure load F caused by the seal gap fluid d and the electromagnetic force F provided by the electromagnetic loading device 13 e .

[0045] f c =F d +F s +F e (1)

[0046] After monitoring and comparing the state parameters of the controllable seal during operation, the state of the seal can be controlled by changing the m...

Embodiment 3

[0073] attached figure 1 A schematic diagram of the mechanical seal structure is given, with Figure 4 A schematic diagram of the structure of a controllable mechanical seal with an electromagnetic loading device is given.

[0074] As mentioned earlier, the closing force of most previous sealing devices is determined by the hydrodynamic and static pressure F in the sealing gap d and spring force F s Composition, in the process of sealing operation, dynamic adjustment cannot be realized, it can only be realized by changing the number of springs in the stop state. Therefore, an electromagnetic loading closing force control device is introduced, which can realize real-time adjustment of the sealing closing force during operation, so as to more effectively study the influence of axial load on the sealing performance and the controllability of the sealing.

[0075] Most of the existing mechanical seals and their device systems test the seal power consumption, including the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com