Medium-and-low temperature hot fume powder feeding type coal powder combustion device and combustion process thereof

A combustion device and pulverized coal technology, which are applied to burners, burners, and combustion methods for burning powder fuels, can solve the problems of large NOx emissions, poor flame stability, and poor adaptability to coal types, and can reduce NOx. The effect of generation, enhanced ignition and stable combustion, and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

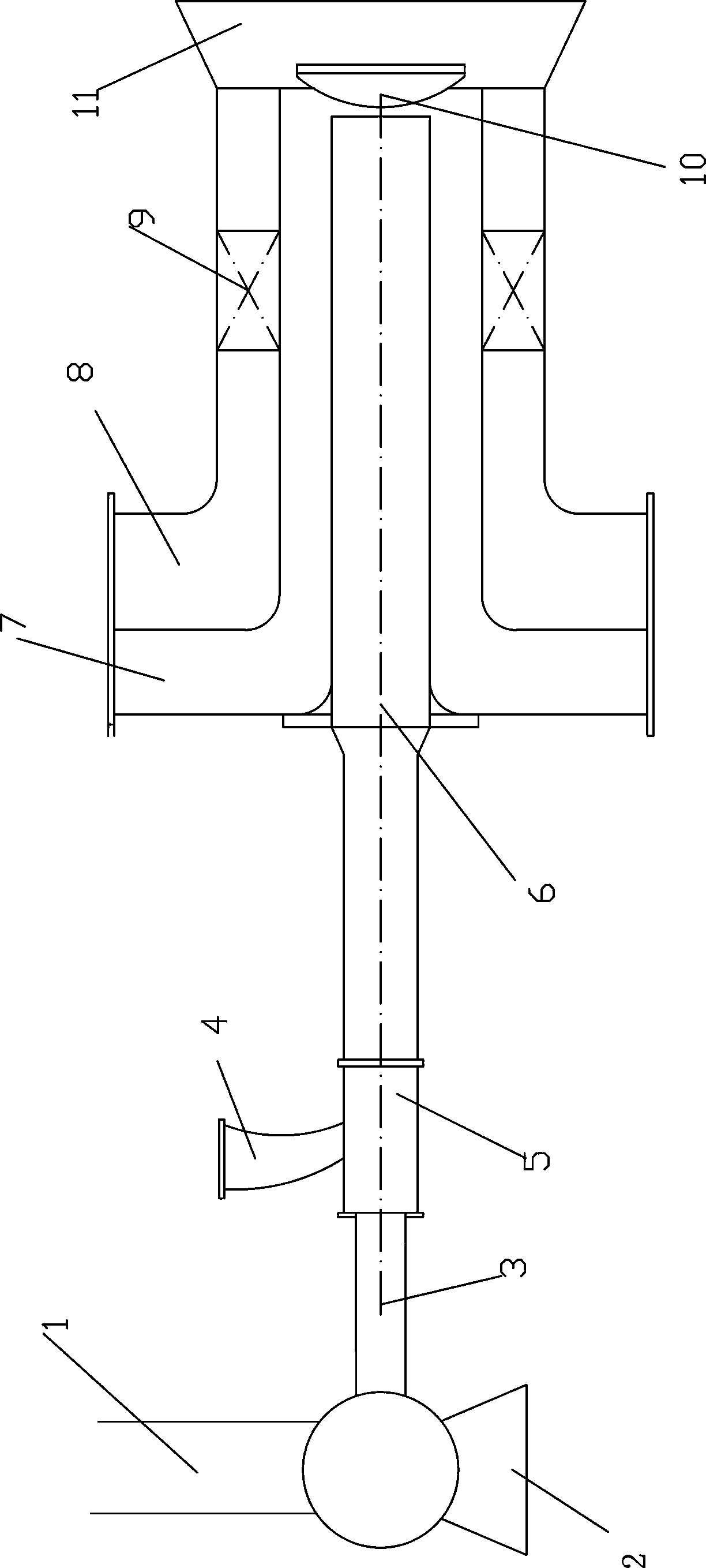

[0020] For a better understanding of the technical features, purpose and beneficial effects of the present invention, now refer to the attached figure 1 The technical solution of the present invention is described in detail as follows, but it should not be understood as limiting the scope of the present invention.

[0021] This embodiment provides a medium and low temperature hot flue gas feeding pulverized coal combustion device, as attached figure 1 As stated, the device includes: Roots fan 2, flue gas circulation pipe 3, pulverized coal mixer powder falling pipe 4, pulverized coal mixer air pipe 5, primary air central pipe 6, inner secondary air pipe 7, outer two Secondary air duct 8, swirl vane 9, blunt body 10, flaring 11, wherein:

[0022] The inlet end of the Roots blower 2 is connected to the flue gas pipeline between the pulverized coal industrial boiler and the air preheater;

[0023] The outlet end of the Roots blower 2 is connected to the inlet end of the flue ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com