Rapid forced cooling furnace device for electronic powder materials

A technology of forced cooling and bulk materials, which is applied in the direction of furnace, furnace components, and the treatment of discharged materials, can solve the problems of long time, unseen, and influence on the quality of electronic powder materials, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

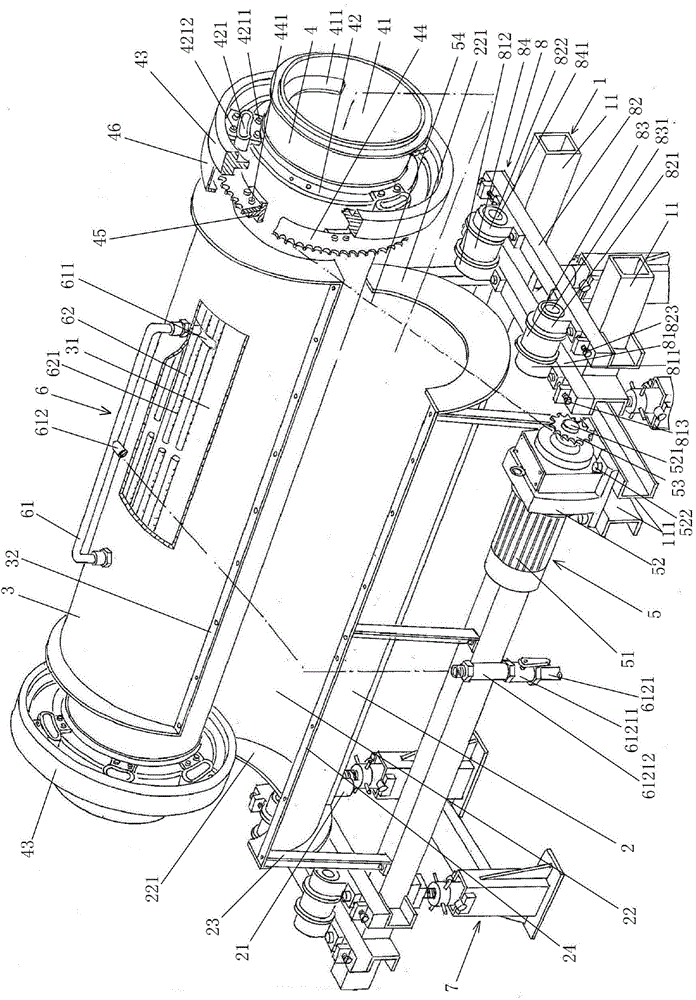

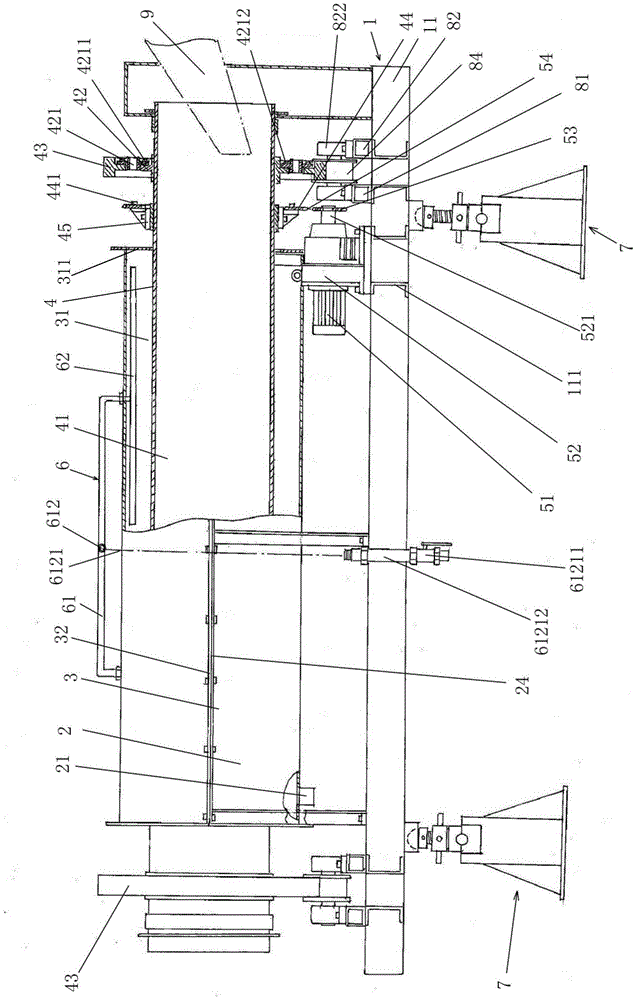

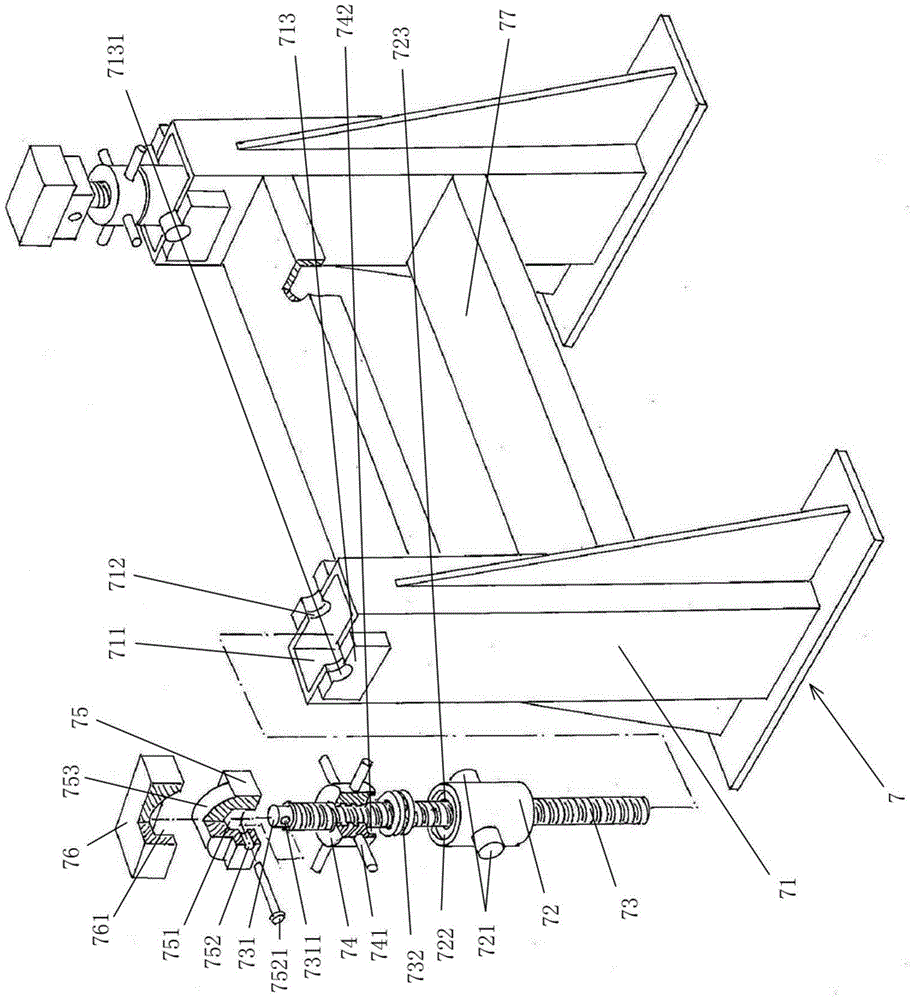

[0023] See figure 1 and figure 2 , given: a frame 1, the frame 1 includes a pair of bottom beams 11 parallel to each other in the length direction, that is to say, the frame 1 is composed of a pair of bottom beams 11, at both ends of the pair of bottom beams 11 Each is provided with a bottom beam height adjustment mechanism 7 which is used to support the bottom beam 11 and can also adjust the distance between the bottom beam 11 and the floor as required, and a pair of bottom beams 11 are respectively provided with a left end and a right end. Cool the drum support mechanism 8 . It can be seen that, in this embodiment, the number of the aforementioned bottom beam height adjustment mechanisms 7 is four, but it is not absolutely limited to four. Each additional bottom beam height adjustment mechanism 7. Preferably, the pair of bottom beams 11 are served by hollow rectangular tubes, that is, the hollow rectangular tubes are used as the bottom beams 11 .

[0024] A lower furnac...

Embodiment 2

[0047] A spiral plate 411 is provided on the cavity wall of the cooling furnace cavity 41 , and the spiral plate 411 extends from the right end port of the cooling furnace cavity 41 to the left end port in a spiral state. Due to the setting of the spiral plate 41, the cooling furnace tube 4 can be arranged without the right end inclined to the left end, and the aforementioned upper and lower furnace shells 3, 2 are the same example. That is to say, if the spiral plate 411 is provided in the cooling furnace cavity 41, the cooling furnace 4, the upper furnace shell 3 and the lower furnace shell 2 can all be arranged horizontally. The feeding pipeline is changed into the feed tank 9 to feed the cooling furnace cavity 41 in a continuous state. All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com