Method for manufacturing electrochromic element

A component manufacturing, electrochromic technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of inability to isolate infrared rays and harmful light wave frequencies, high driving voltage, poor color contrast, etc., and achieve the isolation of infrared rays and harmful light wave frequencies. , long-term color change memory effect, low driving voltage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the above-mentioned purposes, features and advantages of the present invention more understandable, the preferred embodiments of the present invention will be specifically cited below, together with the accompanying drawings, to be described in detail as follows, wherein:

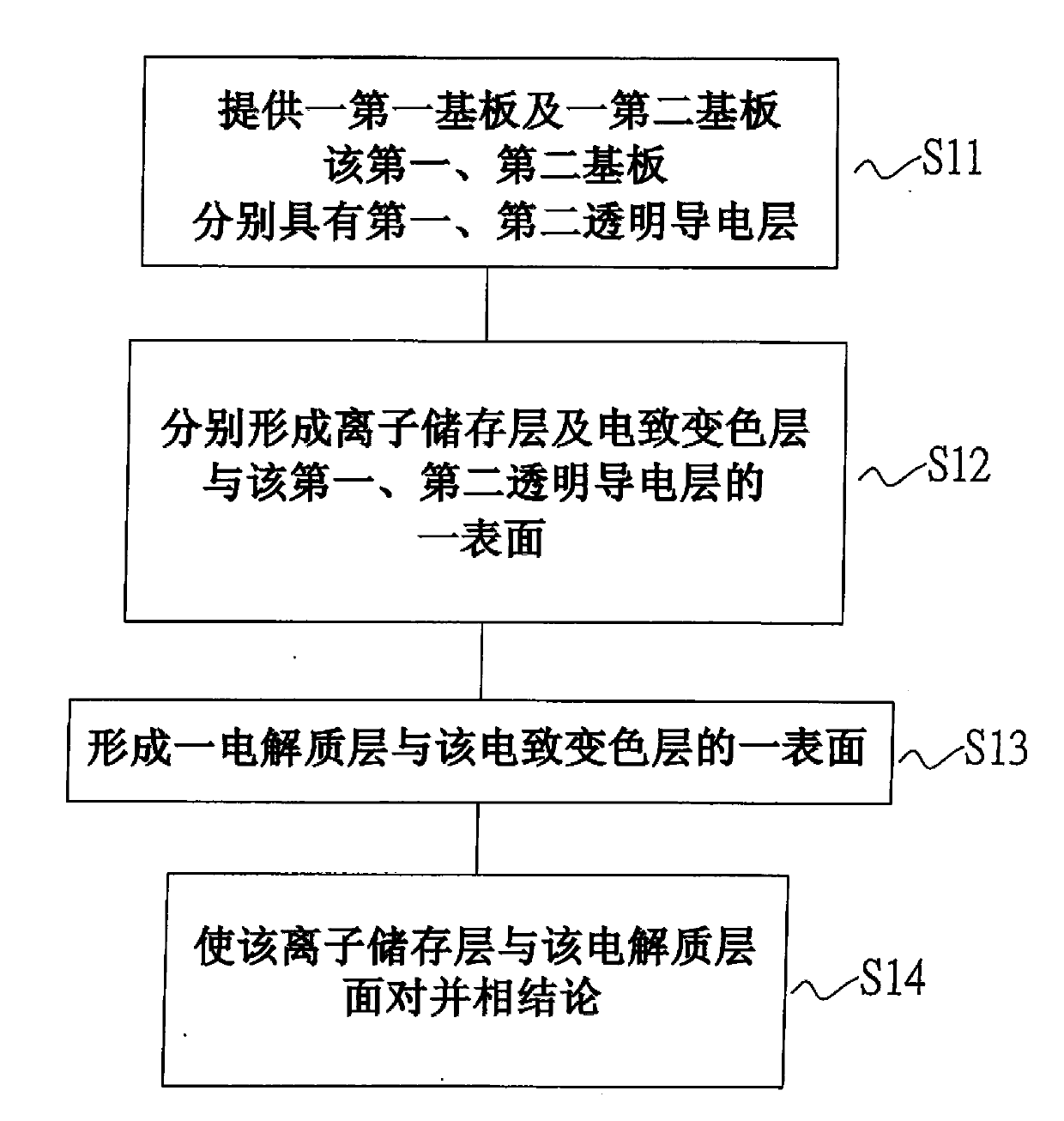

[0037] figure 1 It is a flowchart of a method for manufacturing an electrochromic element according to a preferred embodiment of the present invention; and

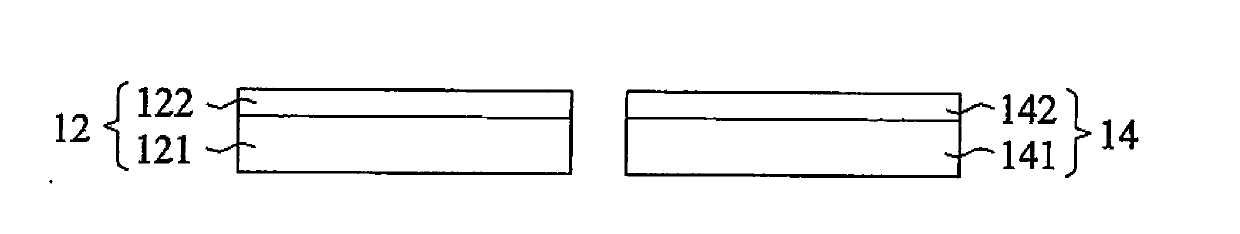

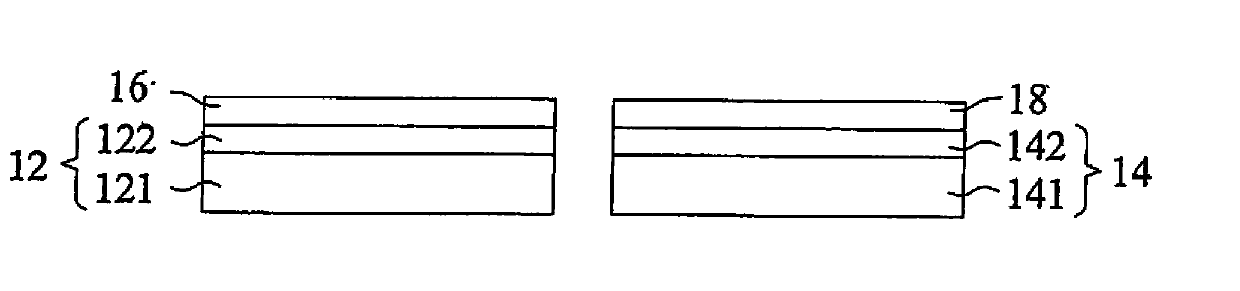

[0038] Figure 2 to Figure 6 It is a schematic diagram of the manufacturing method of the electrochromic element in a preferred embodiment of the present invention.

[0039] Please refer to figure 1 and figure 2 , first proceed to step S11, providing a first substrate (12) and a second substrate (14), the first substrate (12) including a first base material layer (121) and a first transparent conductive layer (122) , the second substrate (14) includes a second base material layer (141) and a second transparent conductive la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com