Self-inspection and burning device and method of stamp hole packaging core board

A burning method and stamp hole technology, applied in the field of core boards, can solve problems such as large program code, long burning time, and reduced production efficiency, and achieve the effects of low operator requirements, saving production steps, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

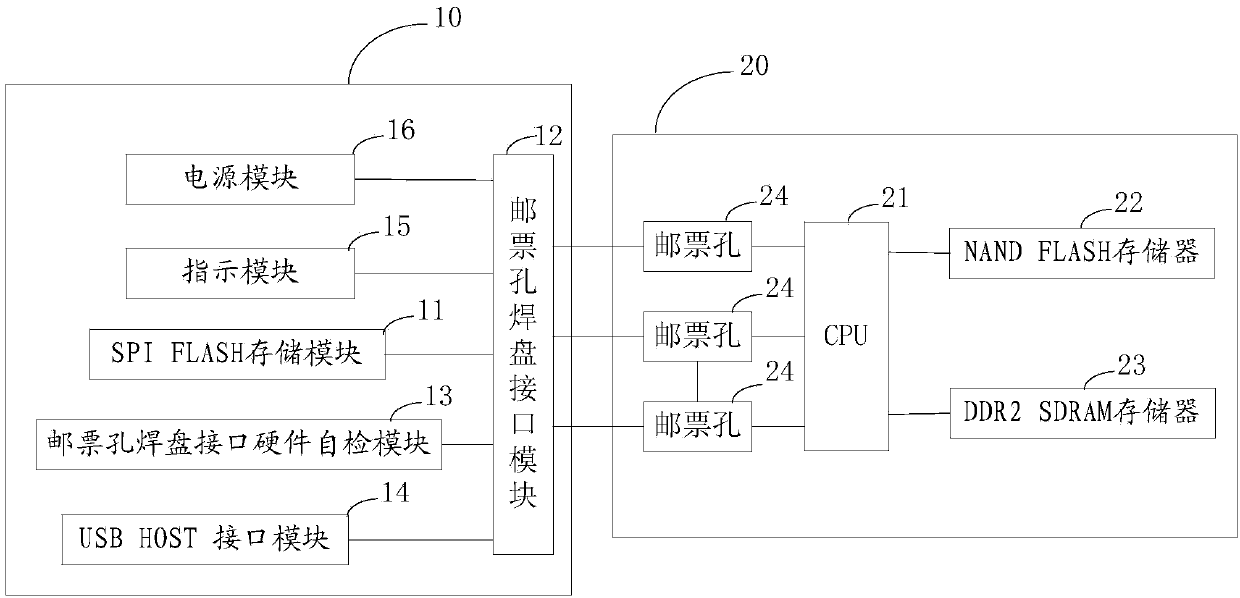

[0034] like figure 1 As shown, the core board self-checking and burning device of stamp hole packaging according to the present invention includes a test board 10, a stamp hole pad interface module 12, and the stamp hole pad interface module 12 has several thimbles, and the thimble One-to-one contact with the stamp hole 24, the test board 10 includes a SPI FLASH (SPI: serial peripheral interface serial peripheral interface) storage module 11, stamp hole 24 pad interface hardware self-test module 13, the stamp The hole pad interface module 12 is electrically connected to the SPI FLASH storage module 11 , and the stamp hole pad interface module 12 is also electrically connected to the stamp hole pad interface hardware self-test module 13 .

[0035] By adopting the self-checking and burning device of the stamp hole packaging interface board of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com