Multi-axis multi-speed motor

A motor and axial technology, applied in the mechanical field, can solve the problems of unsatisfactory use effect and efficiency, and the inability to fully utilize the output mechanical power, and achieve the effects of low noise, simple structure and flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

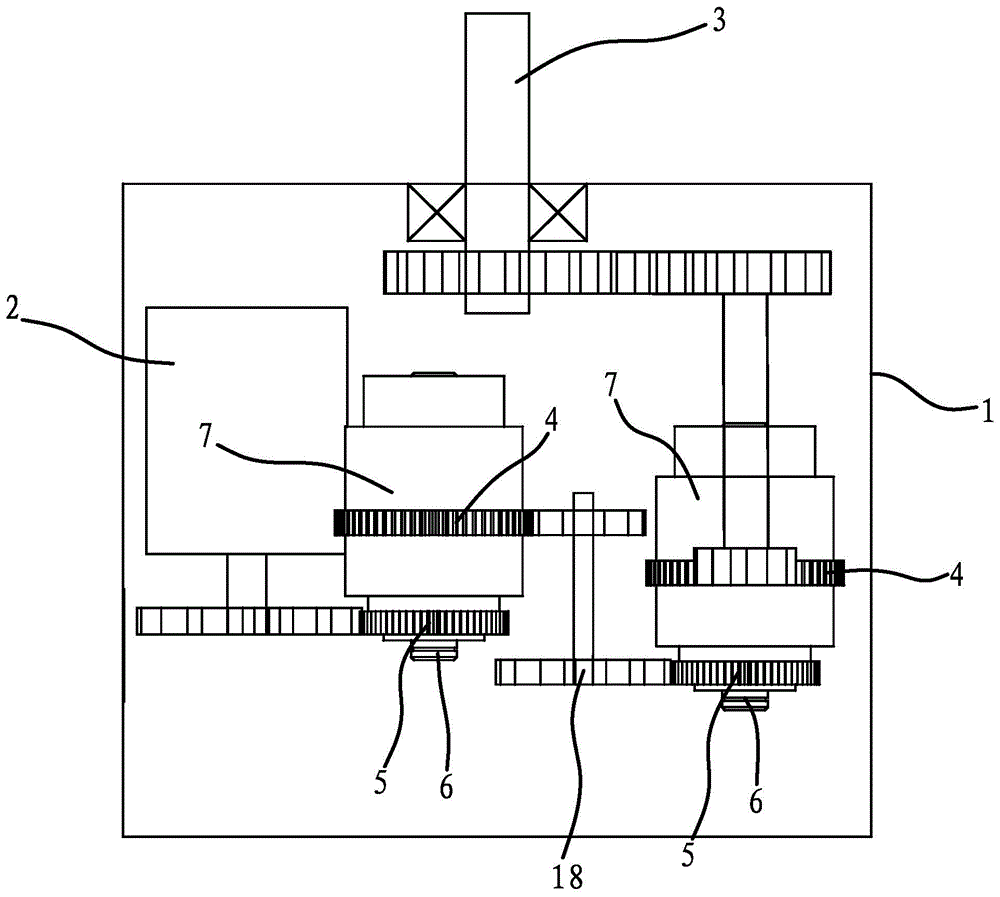

[0031] Such as figure 1 , as shown, the multi-shaft multi-speed motor includes a cylindrical shell 1, the shell 1 is provided with a motor 2 and a transmission 7, and one end of the shell 1 is axially fixed with an output shaft 3. The transmission 7 includes a cylindrical output end 4, an input end 5 and a central shaft 6 fixed axially in the cavity of the output end 4, the output end 4, the input end 5 and the central shaft 6 are coaxially arranged and the input end 5 It can drive the output end 4 to rotate around the central axis 6 , the input end 5 is connected to the rotating shaft of the motor 2 through gear transmission, and the output end 4 is connected to the output shaft 3 through transmission.

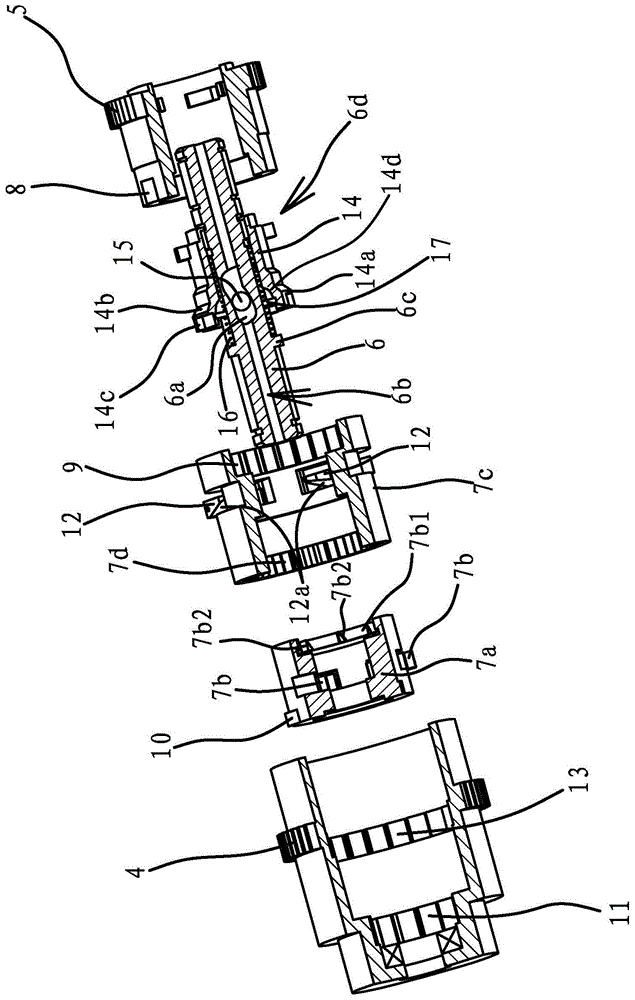

[0032] Such as image 3 and 4 As shown, more specifically, the multi-shaft multi-speed motor also includes a speed regulating mechanism 6d capable of adjusting the output end 4 at different speeds. The cavity of the output end 4 is also provided with a planet wheel frame 7...

Embodiment 2

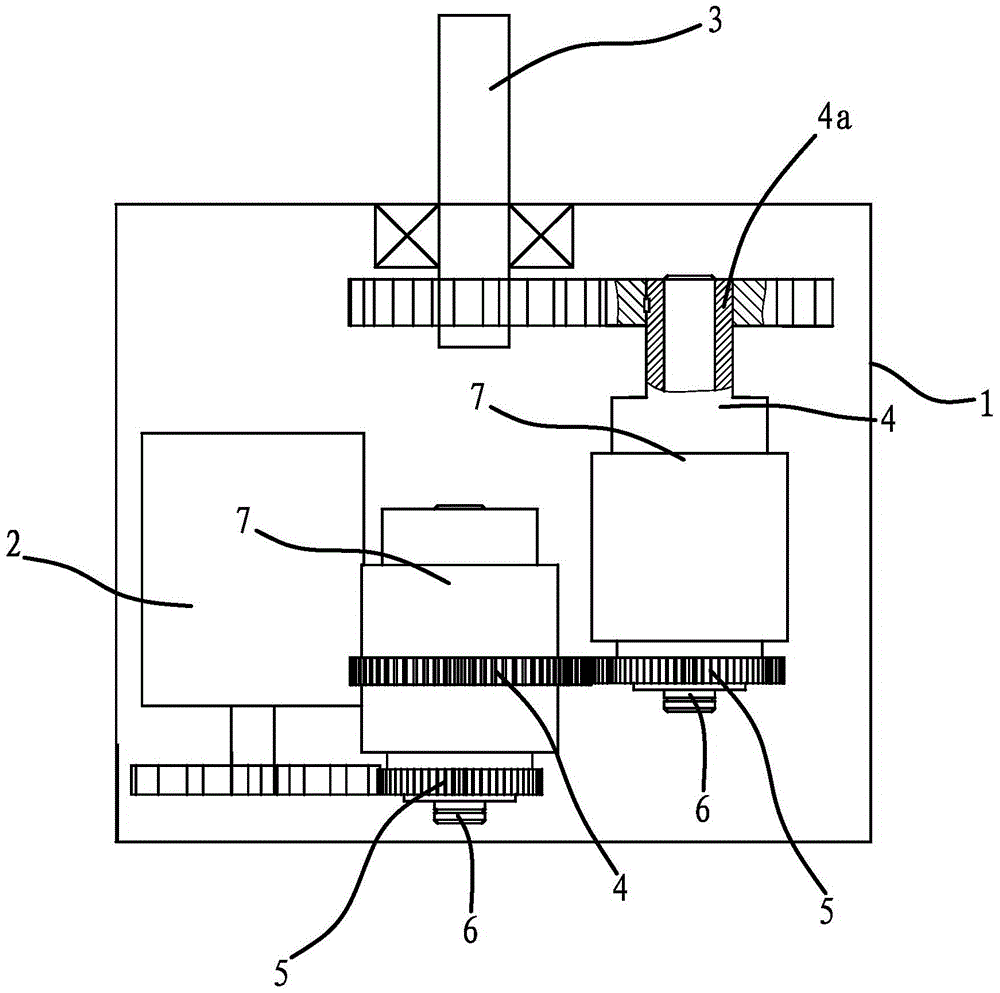

[0040] The structure and characteristics of the multi-axis multi-speed motor of the present embodiment are basically the same as those of the first embodiment, the difference being that the transmission directions of the two speed changers 7 are reversed, figure 2 As shown, the two transmissions 7 are directly connected through gears, that is, the output end 4 of the transmission 7 connected to the rotating shaft of the motor 2 is connected with the input end 5 of the other transmission 7 through gear transmission. The output end 4 of the speed changer 7 connected to the output shaft 3 is fixedly connected with the hollow shaft 4a coaxially arranged therewith, the central shaft 66 is embedded in the cavity of the hollow shaft 4a, and the hollow shaft 4a and the output shaft 3 are passed through a gear Drive connection.

Embodiment 3

[0042] The structure and characteristics of the multi-axis multi-speed motor of this embodiment are basically the same as those of Embodiment 1, the difference is that the speed regulating mechanism includes a drive motor capable of driving the central shaft to rotate, and the central shaft is connected to the inner thread of the clutch sleeve. When in use, the casing of the driving motor is positioned on the casing, and the clutch sleeve is driven to and fro by the forward and reverse rotation of the motor, which has the advantages of simple structure and convenient clutching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com