Rice paste water production process

A production process and technology for rice paste water, applied in the treatment of tobacco, tobacco, application, etc., can solve problems such as bad safety hazards, uneven heating of milled rice, aggravating the environment, etc. The effect of tobacco leaf aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

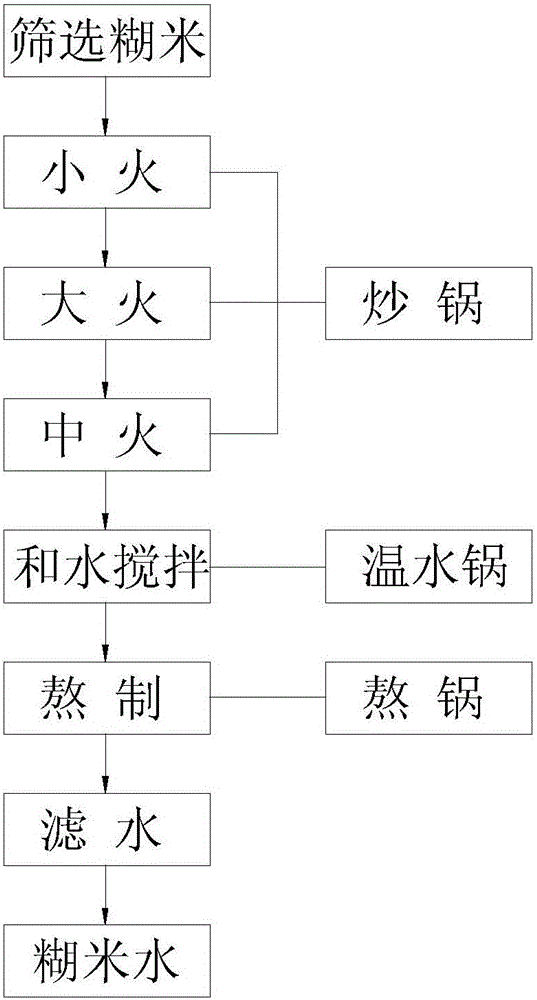

[0025] A kind of paste rice water production process, such as figure 1 described, including the following steps:

[0026] Step 1. Put 6kg of glutinous rice into the frying pan, stir-fry the glutinous rice for 5 minutes with a temperature of 160°C in the pot, and stir-fry at a frequency of 20 times per minute until most of the glutinous rice turns yellow At this time, the paste rice is heated slowly and evenly, and can gradually penetrate into all the paste rice, and it is not easy to paste or carbonize during the frying process; when the paste rice is put into the frying pan, it is generally screened, and the selection of indica rice Or mid-season rice, which has less starch content and less oil content, and chooses glutinous rice with a water content of less than 14%;

[0027] Step 2. Continue to stir-fry the glutinous rice in step 1 with a high fire at a temperature of 320°C for 4 minutes at a frequency of 30 times per minute. The glutinous rice starts to foam and turns in...

Embodiment 2

[0033] A kind of paste rice water production process, comprises the following steps:

[0034] Step 1. Put 6kg of glutinous rice into the frying pan, and stir-fry the glutinous rice for 5 minutes with a temperature of 170°C in the pot. The frequency of stirring is 25 times per minute, until most of the glutinous rice turns yellow At this time, the paste rice is heated slowly and evenly, and can gradually penetrate into all the paste rice, and it is not easy to paste or carbonize during the frying process; when the paste rice is put into the frying pan, it is generally screened, and the selection of indica rice Or mid-season rice, which has less starch content and less oil content, and chooses glutinous rice with a water content of less than 14%;

[0035] Step 2. Continue to stir-fry the glutinous rice in step 1 with a high temperature of 325°C in the pot for 4 minutes at a frequency of 35 times per minute. The glutinous rice starts to foam and turns into a black ball;

[0036]...

Embodiment 3

[0041] A kind of paste rice water production process, comprises the following steps:

[0042] Step 1. Put 6kg of glutinous rice into the frying pan, stir-fry the glutinous rice for 4 minutes with a temperature of 170°C in the pot, and stir-fry at a frequency of 30 times per minute until most of the glutinous rice turns yellow At this time, the paste rice is heated slowly and evenly, and can gradually penetrate into all the paste rice, and it is not easy to paste or carbonize during the frying process; when the paste rice is put into the frying pan, it is generally screened, and the selection of indica rice Or mid-season rice, which has less starch content and less oil content, and chooses glutinous rice with a water content of less than 14%;

[0043] Step 2. Continue to stir-fry the glutinous rice in step 1 with a high temperature of 330°C in the pot for 3 minutes at a frequency of 40 times per minute. The glutinous rice starts to foam and turns into a black ball;

[0044] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com