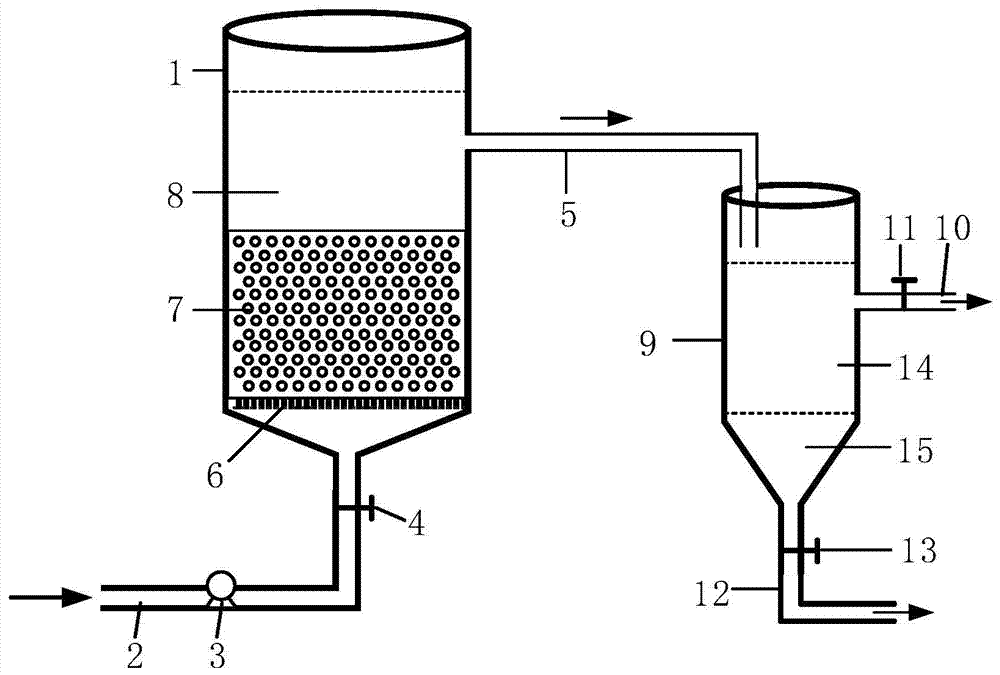

Oil-water separation device and method for water-in-oil emulsion

An oil-water separation device and water-in-oil emulsion technology, which is applied in the field of oilfield chemistry, can solve the problems of increasing the amount of demulsifier, high operating pressure, and increased cost, and achieve the effects of long maintenance-free time, low cost, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

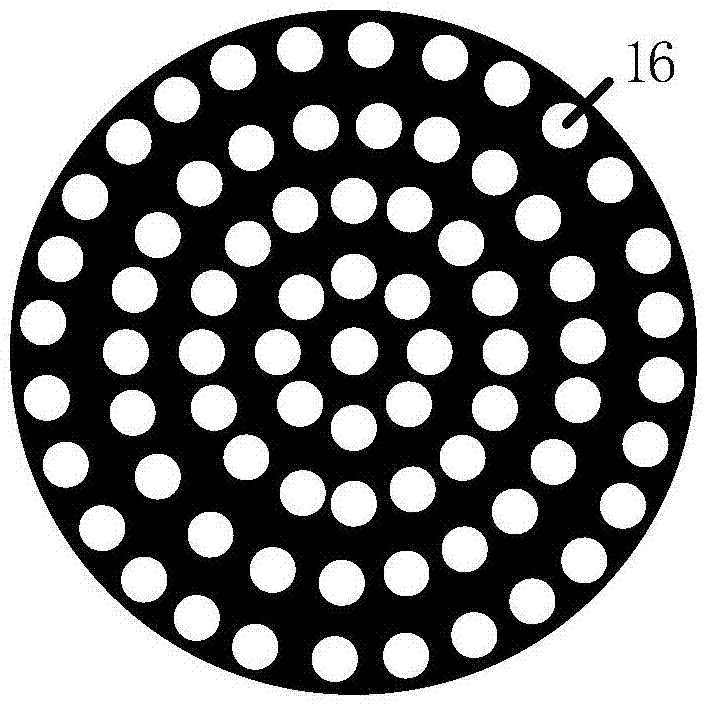

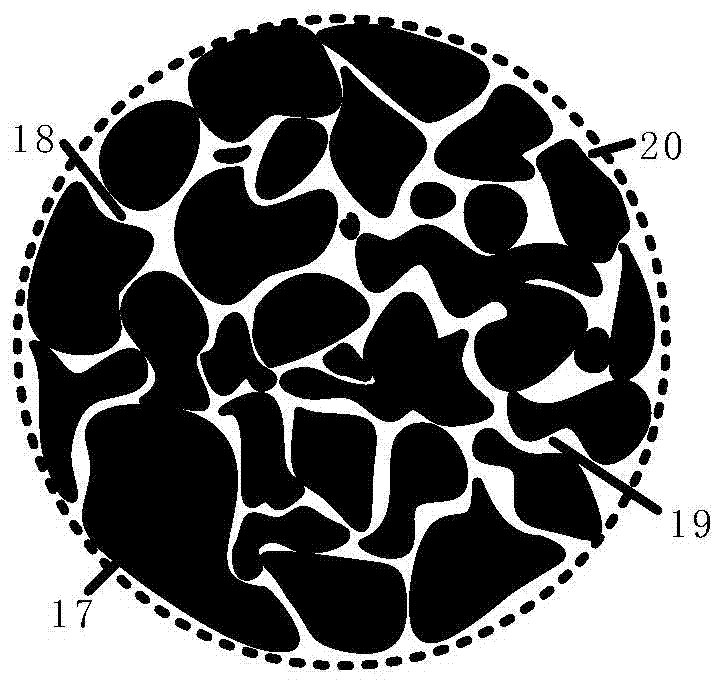

Method used

Image

Examples

Embodiment 1

[0031] Take 1000g of water-in-oil emulsion, divide it into five parts, add demulsifier according to the concentration of 0, 50, 100, 190, 300mg / L respectively and stir well, balance at 70°C for 4 hours, rely on demulsifier and gravity Oil and water are separated by differentiation, and the demulsification efficiencies are: 0, 27.50%, 39.71%, 54.72% and 63.25%.

Embodiment 2

[0033] Take 5000g of water-in-oil emulsion, divide it into five parts, add demulsifier according to the concentration of 0, 50, 100, 190 and 300mg / L respectively and stir well, pump it into the filling thickness at a flow rate of 2mL / min at 21°C It is a 6.8cm short-tube coalescing device. After flowing out of the coalescing device and balancing in the oil-water gravity device for 4 hours, the oil and water are further separated. The measured demulsification efficiency is: 13.48%, 82.19%, 85.11%, 91.34% , 96.59%.

Embodiment 3

[0035] Configure five water-in-oil emulsions with the same demulsifier concentration as in Example 2, pump them into a long tube coalescing device with a filling thickness of 14.0 cm at a flow rate of 2 mL / min, and flow out from the coalescing device in the oil-water gravity device After equilibrating for 4 hours, the measured demulsification efficiencies were: 22.88%, 87.66%, 90.06%, 94.25%, 99.39%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com