Sugar dissolving method in beverage preparation

A technology for dissolving sugar and beverages, applied in chemical instruments and methods, dissolving, dissolving, etc., can solve problems such as bad taste, harsh production environment, high labor intensity, etc., to improve labor intensity and production environment, improve production environment, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

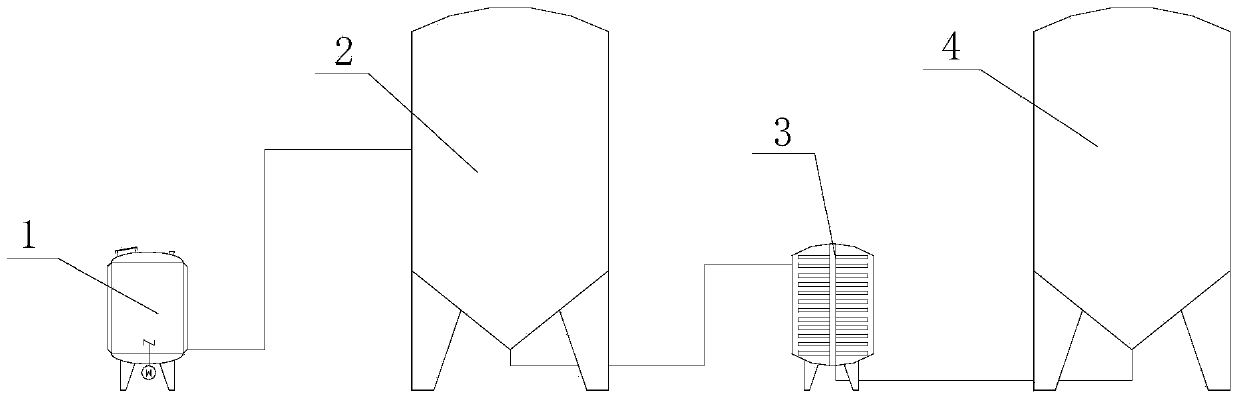

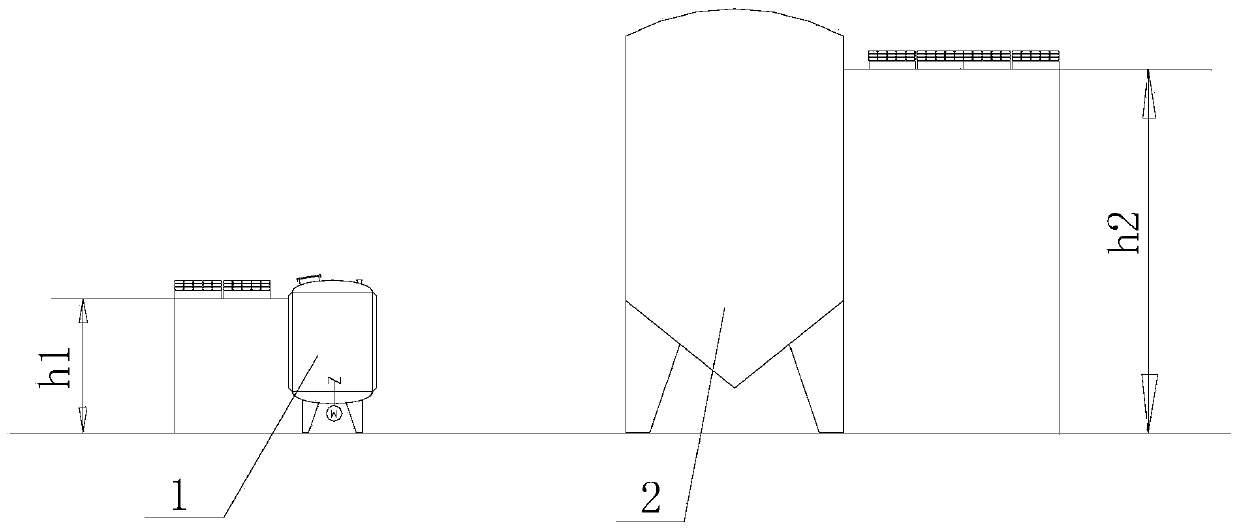

[0016] see figure 1 and figure 2 , the sugar dissolving method in a kind of beverage production of the present invention is carried out in the special sugar dissolving equipment of making beverage, and this sugar dissolving equipment comprises the high-speed shear tank 1, reaction tank 2, filter 3 and storage tank connected in sequence 4; wherein, the height h1 of the high-speed shear tank 1 is 3.5 to 4 meters lower than the height h2 of the reaction tank 2, and the volume of the high-speed shear tank 1 is 7 times smaller than that of the reaction tank 2; the reaction tank 2 is equipped with a stirrer ; Filter 3 is a diatomaceous earth filter.

[0017] Sugar dissolving method of the present invention comprises the following steps:

[0018] In the dissolving step, 60% by weight of granulated sugar and 40% of hot water at 80°C to 85°C are added into the high-speed shear t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com