S-shaped channel solder ejecting head driven by ampere force

A spray head and flow channel technology, applied in the field of S-shaped flow channel solder spray head, can solve the problems of small electromagnetic driving force, large diameter of metal droplets, and low spray frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

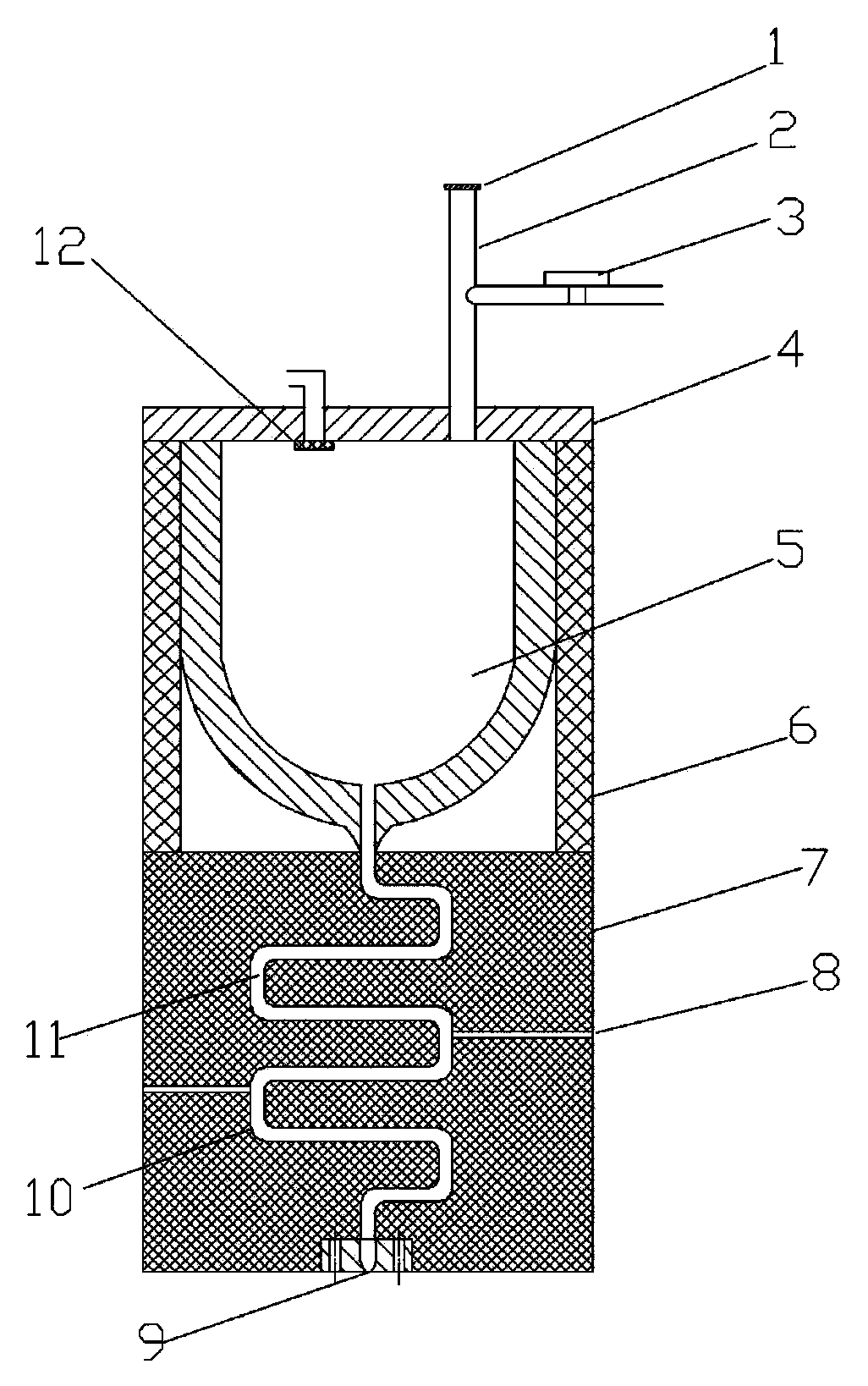

[0017] see figure 1 , the embodiment of the present invention includes a vent hole 1, a vent pipe 2, a solenoid valve 3, a cover plate 4, a heating chamber 5, a heating ring 6, a substrate 7, an electrode extraction hole 8, a nozzle 9, a conductive film 10, a flow channel 11 and a pressure sensor 12.

[0018] The substrate 7 is provided with an S-shaped bent micro-droplet flow channel 11, and the bottom of the flow channel 11 is connected with the nozzle 9, and the nozzle 9 is used for spraying molten solder. A conductive film 10 is plated on the wall of the flow channel 11 as an electrode, and the material of the conductive film 10 is a conductive material. There is also an electrode lead-out hole 8 in the base body, the electrode lead-out hole 8 is connected with the conductive film, and after the electrode is led out, it is connected with an exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com